Full-automatic shale gas content testing analyzer

A shale gas content, test and analysis technology, applied in the field of oil and gas exploration, can solve the problems of incomplete measurement of the desorption environment, low degree of automation, inconvenient portability, etc., and realize the visualization of the whole test process, full automation, and easy packing carrying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

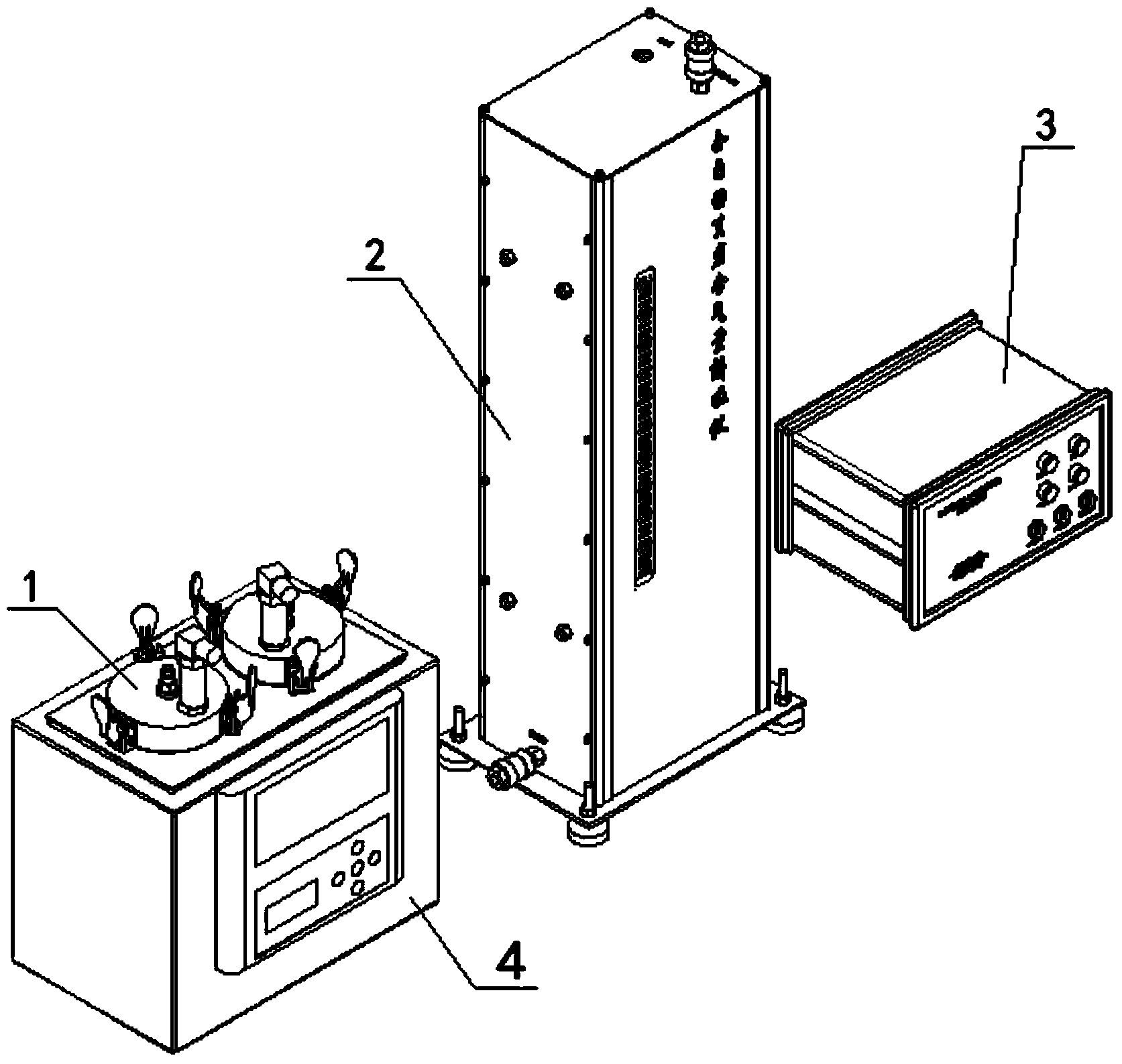

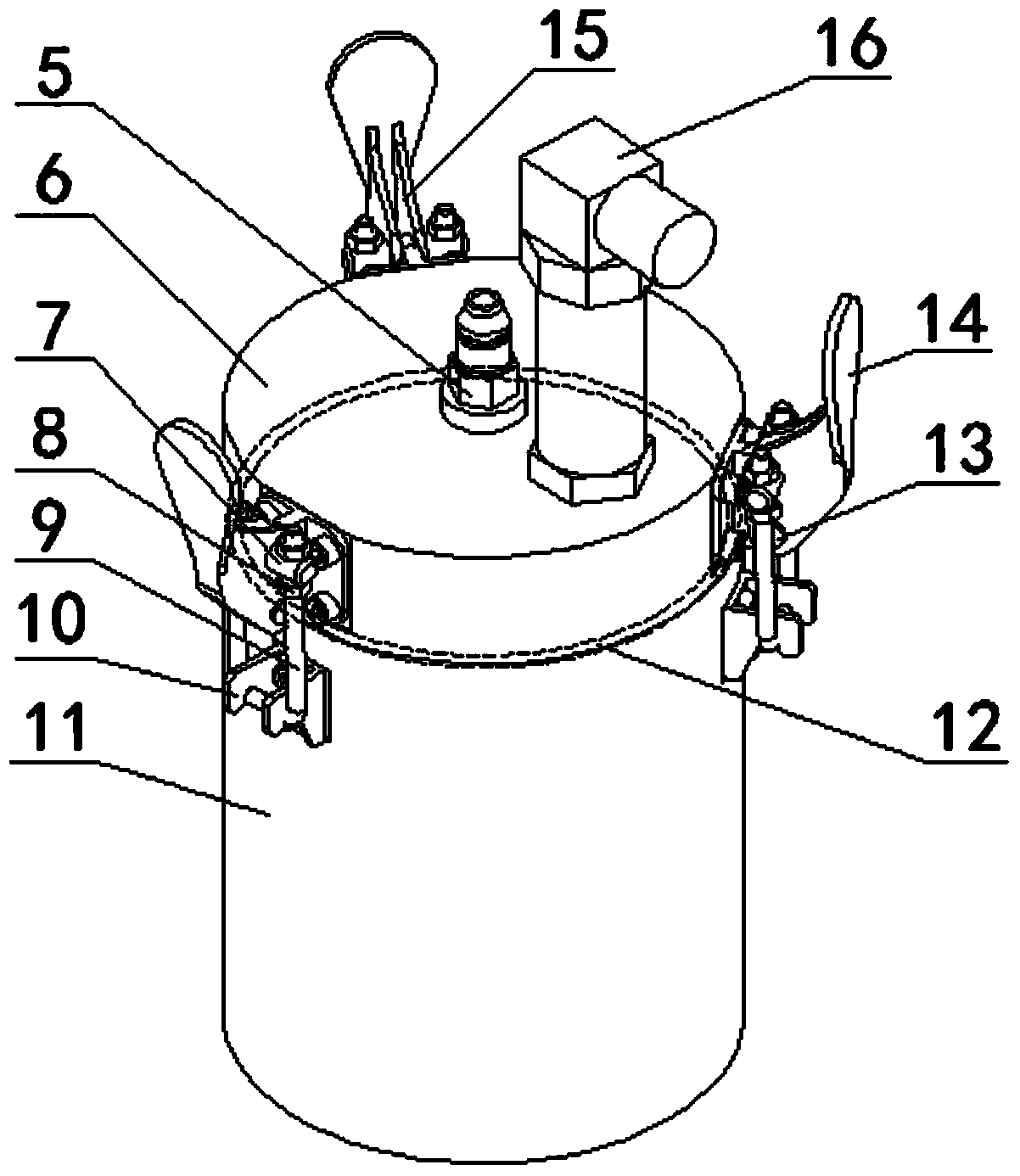

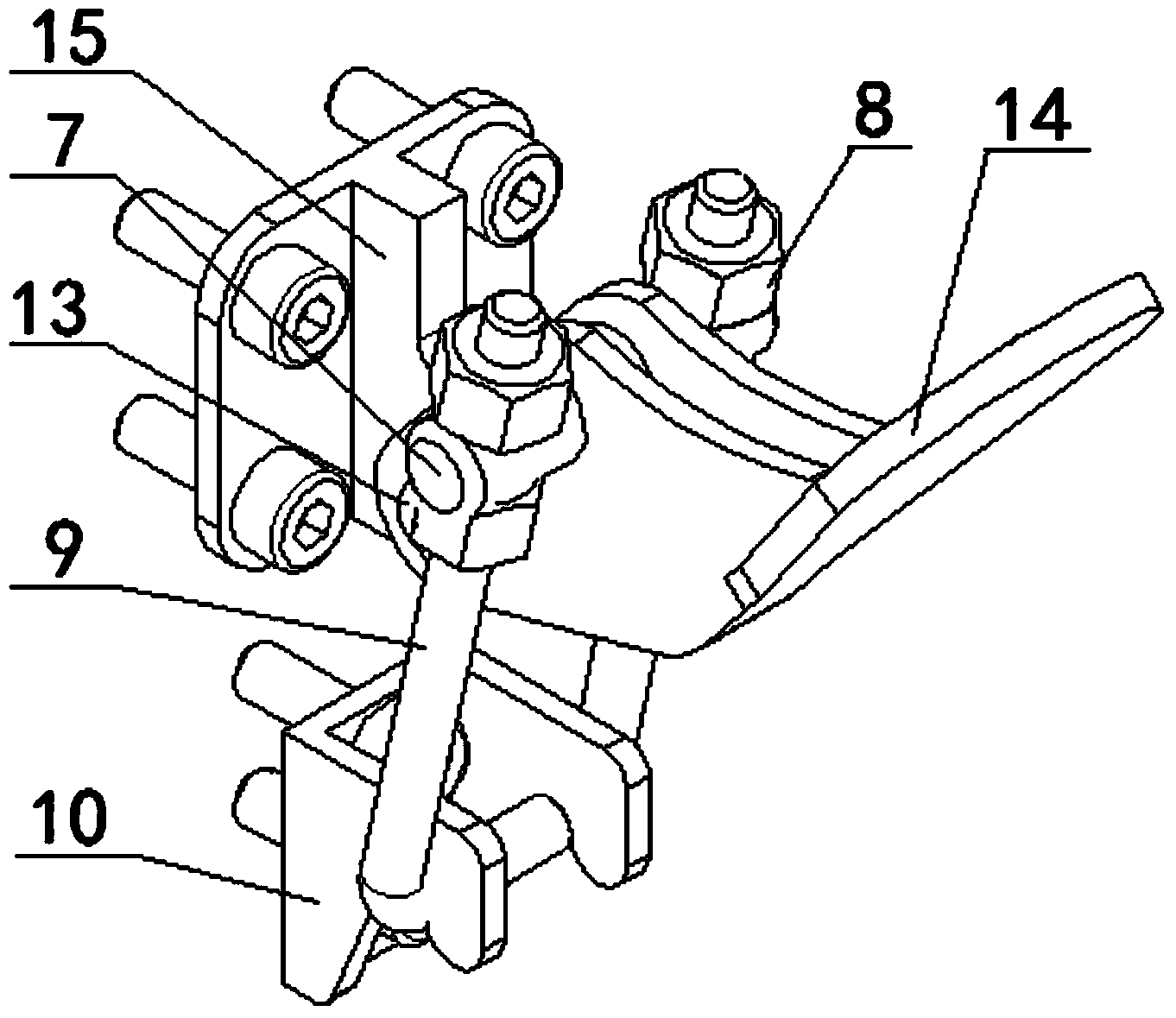

[0033] Embodiment 1: a kind of automatic shale gas content test analyzer provided by the present invention, its overall appearance is as follows figure 1 , including desorption device 1, gas detection device 2, data acquisition box 3 and host computer; see figure 2 , the desorption device 1 contains a constant temperature water bath 4 and two desorption tanks, and the two desorption tanks are placed in the constant temperature water bath 4; each desorption tank consists of a tank cover 6, a tank body 11, a quick connector A5, a quick clamp, The temperature sensor A16 is composed of an O-shaped sealing ring 12 between the tank cover 6 and the tank body 11; three matching quick clamps are evenly distributed on the upper part of the tank body 11 and around the tank cover 6, so that the gap between the tank body 11 and the tank cover 6 is formed. The press-button connection; the quick connector A5 and the temperature sensor A16 are installed on the tank cover 6 through threads; t...

Embodiment 2

[0040] Embodiment 2: Apply the fully automatic shale gas content test analyzer provided in Example 1 to test the shale gas content.

[0041] The process of desorption gas measurement is as follows: before the test starts, the sample is first quickly loaded into the desorption tank, and the tank body 11 and the tank cover 6 are tightly pressed with quick clamps to seal the desorption tank; quickly put the desorption tank into the desorption tank. In the constant temperature water bath box 4 of the set temperature, connect the conduit, especially the conduit between the quick connector A5 connected on site and the manual valve 39.

[0042] Liquid is injected into the gas collecting bottle 29 through the water injection valve 42, and then the gas desorption begins. The gas desorbed in the desorption device 1 passes through the conduit 24, passes through the manual valve 39, connects the pressure sensor 37, and finally enters the gas collection bottle 29, and the liquid in the gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com