Preparation method and application of PD composite mineral admixture containing silica fume

A composite admixture and composite mineral technology, which is applied in the preparation and application of PD composite mineral admixture containing microsilica, and achieves the effects of good popularization and application value, beneficial to industrial production, and comprehensive utilization of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The test material of the PD composite mineral admixture of the present invention, the pozzolan raw material selects the pumice produced in Baoshan, Yunnan, the raw material of the stone powder selects the dolomite sand produced in Baoshan, Yunnan, and the microsilica selects the encrypted silicon powder and gypsum of Zhenyuan Silicon Industry Co., Ltd. in Baoshan, Yunnan. Dihydrate gypsum produced in Yongping, Yunnan was selected. The chemical compositions of the various materials are listed in Table 3.

[0028] Table 3 The chemical composition of each component material used in the test

[0029] material name

Embodiment 2

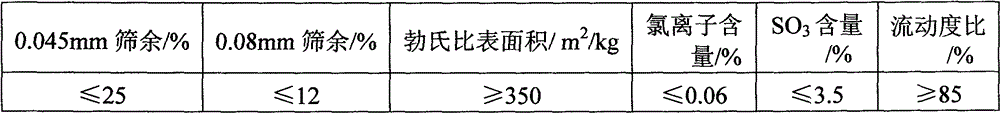

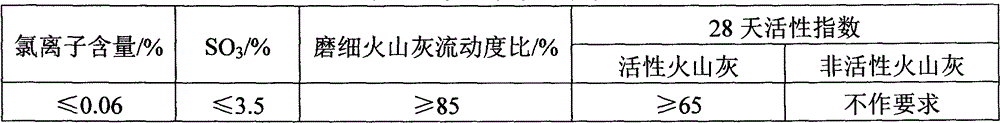

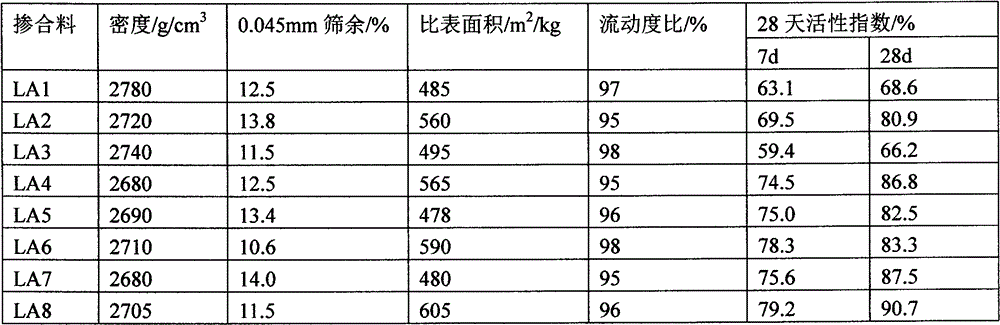

[0031] The four raw materials in Example 1 were used to prepare 8 groups of test admixtures, namely LA1, LA2...LA8, and LA6 and LA8 were selected to be mixed with gypsum, and the amount of silicon powder was reduced at the same time. The preparation of the admixture is shown in Table 4. Take the 8 groups of test admixtures in Table 4 respectively, and refer to the detection method specified in JG / T 315 "Natural Pozzolan Materials Used in Mortar and Concrete" to test the relevant parameters and test the admixture The test results of the physical properties of the materials are shown in Table 5.

[0032] Table 4 Preparation of test admixtures

[0033] Admixture Code

Volcanic ash / %

Stone powder / %

Silica fume / %

Gypsum / %

Remark

LA1

100

0

0

0

single mixed

LA2

85

0

15

0

double doping

LA3

0

100

0

0

single mixed

LA4

0

85

15

0 ...

Embodiment 3

[0043] Five kinds of admixtures LA1, LA2, LA4, LA7, and LA8 in this test plan were used to prepare ready-mixed commercial concrete C30. The trial strength was 38.5MPa and the slump was 180. The cement was selected from Kunming Iron and Steel Jiahua Xilin brand P.O42 .5, the Nai system retarding high-efficiency superplasticizer, the mix ratio is shown in Table 6, and the concrete physical performance test results are shown in Table 7.

[0044] Table 6 C30 mix ratio of pumped concrete (unit: kg)

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com