Front and rear end-mounted compaction wheel device for road roller and operation method thereof

An operation method and technology of road rollers, which are applied in the field of construction machinery, can solve problems such as time-consuming and labor-consuming, high cost, and low flatness, and achieve the effects of saving manpower and material costs, avoiding repeated operations, and simple replacement and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

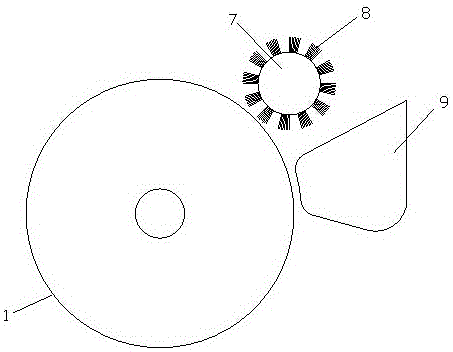

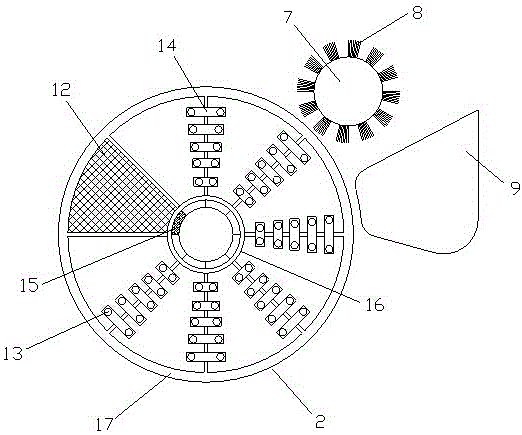

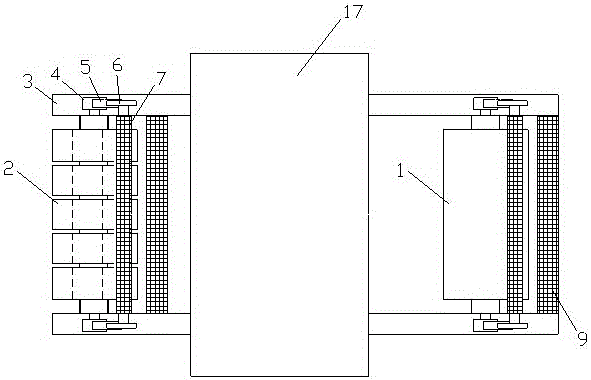

[0036] refer to Figure 1 to Figure 4 As shown, a split arrangement of the pressure roller of a road roller includes a wheel body 1, a wheel body 2 and a car body 18, the wheel body 2 2 is located in front of the car body 18, and the wheel body 1 is located in the car body 18 At the rear, the wheel body one 1 and the wheel body two 2 are all equipped with a pair of pressure wheel frames 3, and the bottom of the pressure wheel frame 3 corresponding to the wheel body one 1 is provided with lifting wheels, and the pressure wheel frame 3 is provided with a first wheel. Gear 4, relay gear 5 and tail gear 6, described head gear 4 is linked with wheel body one 1 or wheel body two 2, and the lifting device in the lifting wheel is an air pump etc., and described tail gear 6 is linked with brush wheel 7, The brush wheel 7 is provided with bristles 8, and there is a recovery box 9 corresponding to the bottom of the brush wheel 7. One side of the pressure wheel frame 3 is provided with tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com