Curing agent for solid waste treatment and application thereof

A solid waste and curing agent technology, applied in the field of water-based drilling waste cuttings, can solve the problems of difficult secondary curing, high chemical oxygen demand, poor plasticity of cuttings, etc., to achieve energy saving and environmental protection, high efficiency Cured, low strength and brittle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: Preparation method of curing agent for solid waste treatment of the present invention

[0037] The preparation method of the curing agent for solid waste treatment provided by the present invention comprises the following steps: (1) accurately weighing each material used; (2) transporting the accurately weighed material to a sealed mixer; (3) mixing in a sealed Stirring in the machine; (4) forming the solid waste treatment solidifying agent and packing the finished product for later use.

[0038] In the present invention, stir in a sealed mixer for 2h-3h.

[0039] The preparation method of the curing agent for solid waste treatment of the present invention comprises weighing materials, adding materials, adding 10% water, and then mixing.

Embodiment 2

[0040] Embodiment 2: The method of using the curing agent for solid waste treatment of the present invention

[0041] The method for using the curing agent for solid waste treatment provided by the present invention comprises the following steps: (1) injecting waste cuttings into the pool and stirring evenly; (2) adding the solid waste treatment solidifying agent into the pool in the first step (1) ; (3) stirring the waste cuttings after adding the curing agent for solid waste treatment; (4) drying the stirred mixture to obtain a solidified product.

Embodiment 3

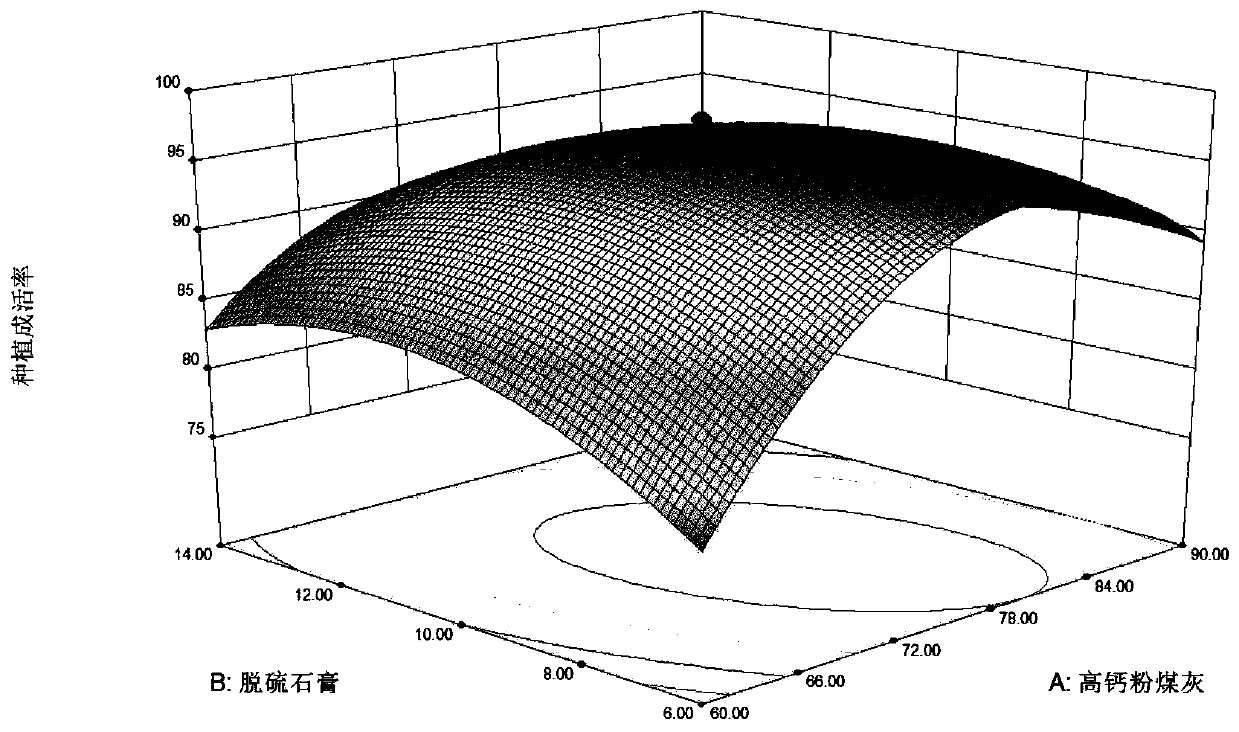

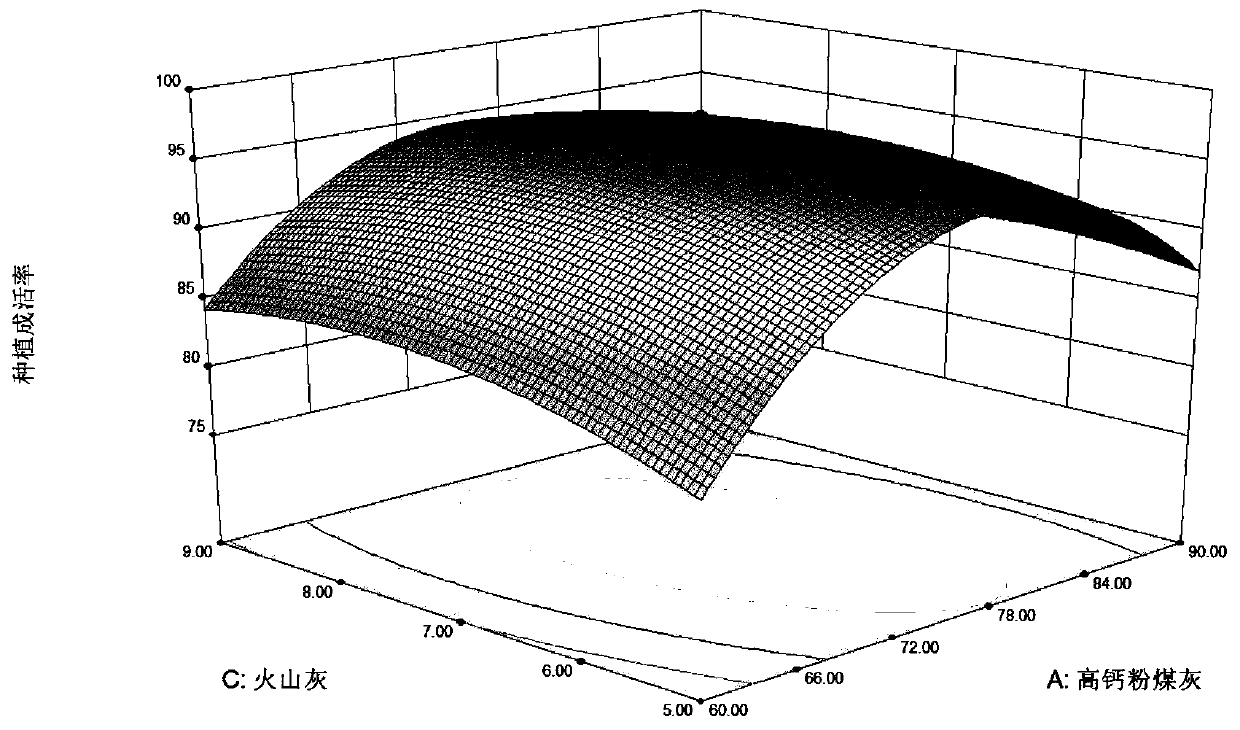

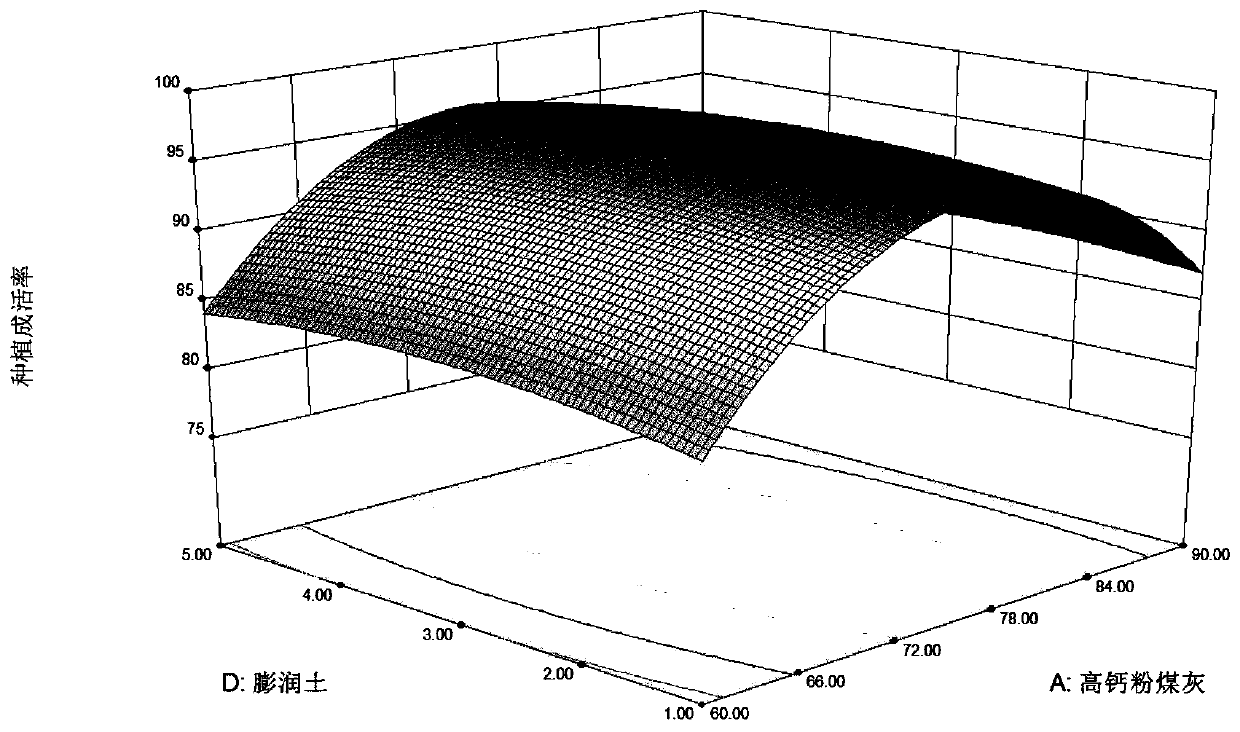

[0042] Embodiment 3: Solid waste treatment solidifying agent of the present invention

[0043] The invention provides a curing agent for solid waste treatment, comprising the following components: 75 tons of high-calcium fly ash; 10 tons of desulfurized gypsum; 7 tons of volcanic ash; 3 tons of bentonite; 3 tons of calcium chloride; 2 tons of sodium sulfate .

[0044] In the present invention, bentonite is nano-scale bentonite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com