Pozzolana mixture as well as preparation method and application thereof

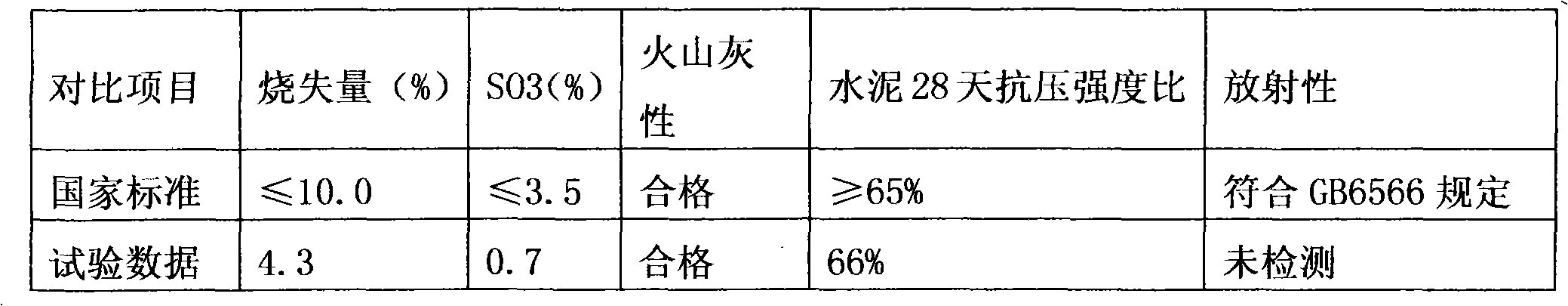

A technology of admixture and volcanic ash, applied in the field of cement admixture, can solve problems such as unguaranteed quality, environmental pollution, increased energy consumption, etc., and achieve the effect of large adjustment space for output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

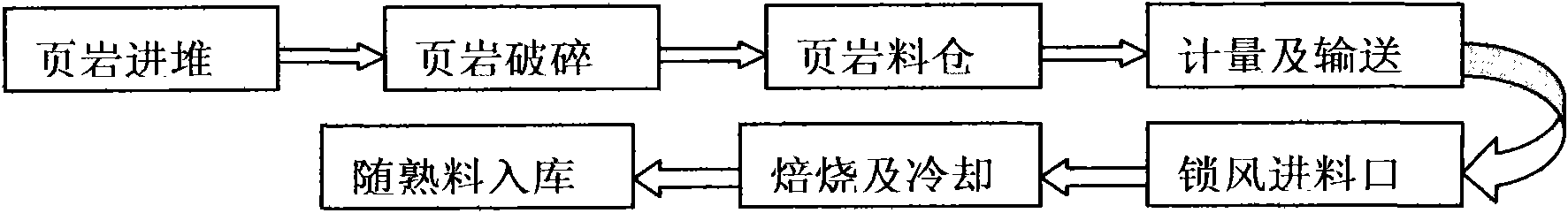

[0023] A kind of pozzolanic mixed material in cement, its preparation method, comprises the following steps, as figure 1 Shown:

[0024] 1) Screening and crushing the shale as raw materials, the mass percentage of water in the shale is 9.8%, and the crushing particle size is 10mm;

[0025] 2) Shale is fed into the bin and measured;

[0026] 3) 30 tons of shale and 200 tons of kiln clinker are alternately covered and roasted at 600°C for 15 minutes to obtain a kiln clinker-burned shale mixture;

[0027] 4) cooling the calcined clinker-burned shale mixture to 60° C. to obtain a pozzolanic mixture.

[0028] 5) The admixture ratio of pozzolanic admixture and other admixtures is 40% (excluding gypsum) when finally producing composite 325 cement; the admixture ratio of pozzolanic admixture is 12% when producing ordinary 425 cement, and Other mixed materials can be added up to 20% (without gypsum).

Embodiment 2

[0030] A kind of pozzolanic mixed material in cement, its preparation method, comprises the following steps:

[0031] 1) Screening and crushing the shale as raw materials, the mass percentage of water in the shale is 9%, and the crushing particle size is 20mm;

[0032] 2) Shale is fed into the bin and measured;

[0033] 3) 40 tons of shale and 200 tons of kiln clinker are alternately covered and roasted at 1000°C for 20 minutes to obtain a kiln clinker-burned shale mixture;

[0034] 4) Cooling the calcined clinker-burned shale mixture to 80°C to obtain a pozzolanic mixture.

[0035] 5) The admixture ratio of pozzolanic admixture and other admixtures is 45% (excluding gypsum) when finally producing composite 325 cement; the admixture ratio of pozzolanic admixture is 15% when producing ordinary 425 cement, and The proportion of other mixed materials can reach 25% (excluding gypsum).

Embodiment 3

[0037] A kind of pozzolanic mixed material in cement, its preparation method, comprises the following steps:

[0038] 1) Screening and crushing the shale as raw materials, the mass percentage of water in the shale is 9.9%, and the crushing particle size is 30mm;

[0039] 2) Shale is fed into the bin and measured;

[0040] 3) 50 tons of shale and 200 tons of kiln clinker are alternately covered and roasted at 800°C for 25 minutes to obtain a kiln clinker-burned shale mixture;

[0041] 4) Cooling the calcined clinker-shale mixture at 70°C to obtain a pozzolanic mixture.

[0042] 5) The admixture ratio of pozzolanic admixture is 42% (excluding gypsum) in the final production of composite 325 cement; the admixture ratio of pozzolanic admixture in the final production of ordinary 425 cement is 18%, and it is mixed with other admixtures The ratio can reach 23% (without gypsum).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com