Self-hydration activated pavement base layer

A pavement base and active technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of unsuitable use in soft soil areas, insufficient use of steel slag activity, high density of steel slag, etc., and achieve saving of piles The effect of saving land, good strength deferral, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Wuhan steel slag coarse aggregate base: First, Wuhan steel slag and power plant slag are designed as mineral mixture according to reasonable gradation, and then weighed according to the design components (see Table 1 for the weight of each raw material), and compaction test is carried out to determine Optimum water content and maximum dry density, according to the controlled degree of compaction molding test pieces and determine their unconfined compressive strength. The steel slag is natural slag from WISCO, the particle size is less than or equal to 31.5mm, and the particle size of power plant slag and granular slag is less than or equal to 5mm. The amount of slag powder is changed, and the unconfined compressive strength test is carried out according to the degree of compaction of 97%. 6 days, immersion in water for 1 day) The specific results of unconfined compressive strength are shown in Table 1.

[0045] It can be seen from the performance indicators in Table 1 t...

Embodiment 2

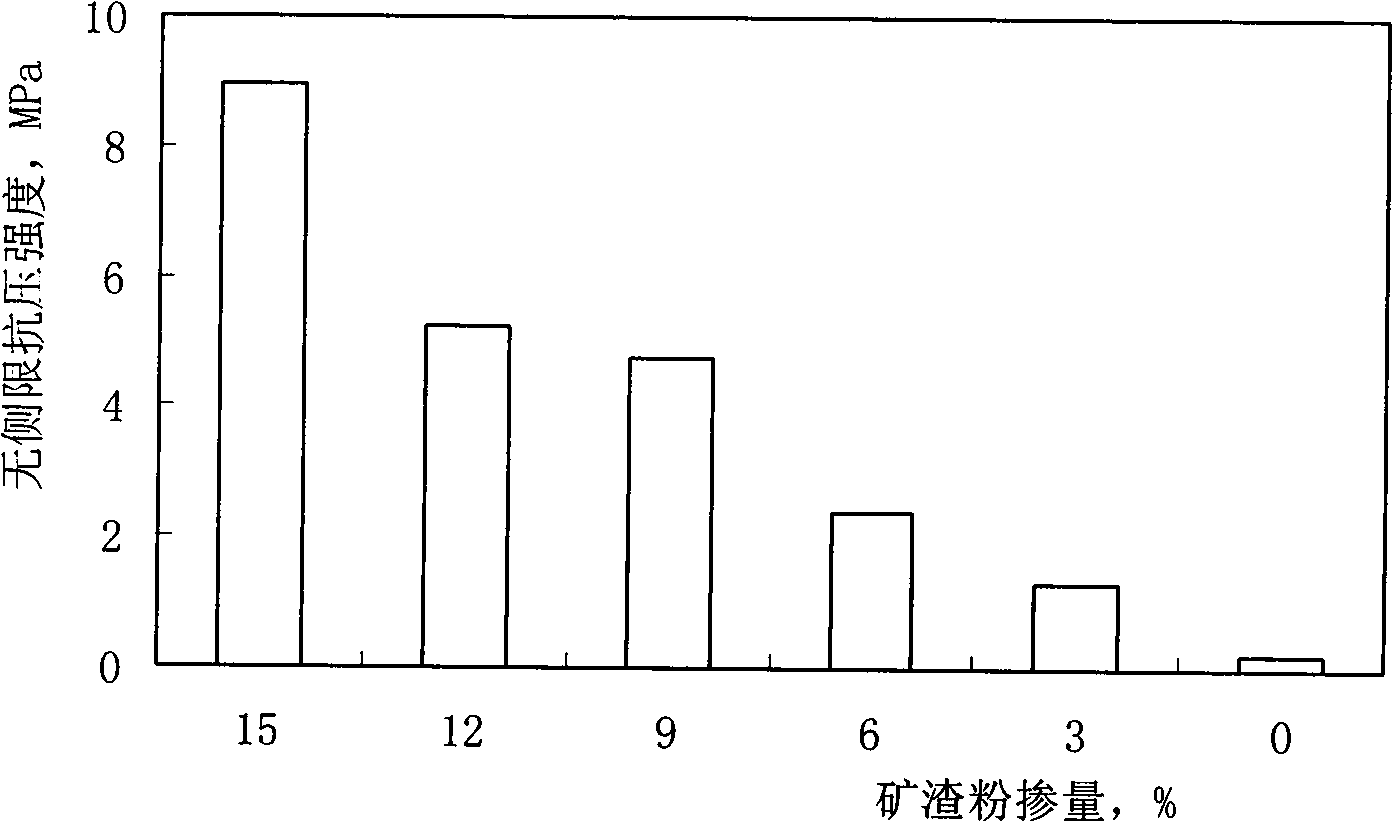

[0047] WISCO Steel Slag Fine Aggregate Base: WISCO natural slag is used for steel slag, the particle size is less than or equal to 4.75mm, the dosage is 50%, and the dosage of power plant slag is 35%. The parts by weight are shown in Table 2), and the unconfined compressive forming test was carried out by 97% compaction, and the unconfined compressive strength results in 7 days (6 days for health preservation, 1 day for immersion) are shown in Table 2 and figure 2 shown.

[0048] From Table 2 and figure 2 It can be seen from the figure that: in the case of fixing the content of steel slag and power plant slag, with the decrease of slag powder content, the 7-day unconfined compressive strength shows a regular decreasing trend, that is, for steel slag fine aggregate, by adjusting the granularity The ratio of slag and slag powder can also be used to formulate the components of the self-hydration activated pavement base compound suitable for the pavement sub-base and the base. ...

Embodiment 3

[0050] Egang Steel Slag Coarse Aggregate Base: Egang steel slag and power plant slag are designed as mineral mixtures according to reasonable gradation, and then weighed according to the designed components for testing. In the experiment, the particle size of Egang’s natural slag is less than or equal to 19mm, the dosage is 50%, the dosage of power plant slag is 35%, and the dosage of slag powder is changed (see Table 3 for the weight parts of granular slag and slag powder in the proportion). The unconfined compressive forming test with a solidity of 97% is shown in Table 3.

[0051] From the performance indicators in Table 3, it can be seen that the self-hydrating activated pavement base that meets the performance indicators of the pavement subbase and base can also be prepared by using steel slag from Egang and adjusting the amount of slag powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com