Modification of properties of pozzolanic materials through blending

A technology of volcanic ash and characteristics, applied in the field of volcanic ash, can solve problems such as slow response and hindering strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

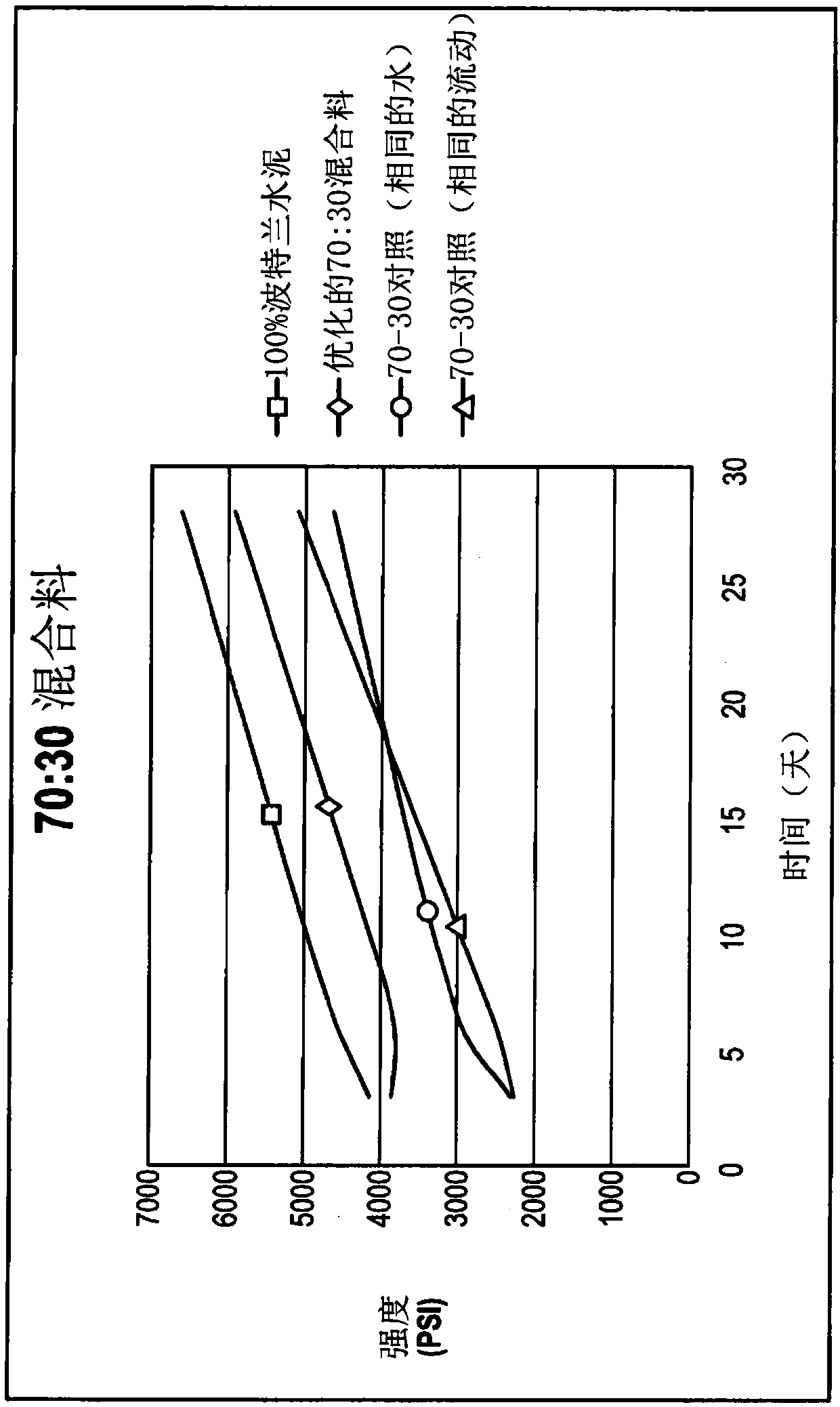

[0134] Examples 1-4 illustrate the effect of particle size optimizing a 70:30 mixture of Portland cement and fly ash. The Portland cement used in each of Examples 1-4 was an approximate Type II cement made by more finely grinding Type V cement. Example 1 is a particle size optimized 70:30 cement / pozzolan mix. It uses a graded Portland cement designated "Cement #11" by passing an approximate Type II Portland cement through a miniature air classifier manufactured by Progressive Industries, Sylacauga, Alabama, and Obtained by collecting fine particles. Example 1 also uses a classed fly ash classified as "fly ash 8z1", which is obtained by passing class F fly ash through an air classifier twice, first removing most of the fines below about 10 μm and then about Most of the fine particles above 50μm. The air classifier was a model CFS 8HDS from Netzsch-Condux Mahltechnik GmbH, Hanau, Germany. Examples 2 and 3 are both 70:30 control mixes of Portland cement and fly ash using uncl...

Embodiment 5-14

[0145] Other mortar compositions (ie 60:40 mix and 70:30 mix) were made using cement #11 and fly ash 8z1. Additionally, a mortar composition was made using another graded cementitious material identified as "Cement #13" and another graded fly ash identified as "Fly Ash 7G". Cement #13 was graded in the same facility as cement #11. The particle size distributions of cement #11, cement #13, and control cement were determined at a grading facility using a Beckman Coulter LS 13 320 X-ray Diffraction Analyzer and are listed in Table 3 below.

[0146] table 3

[0147]

[0148]

[0149] Fly ash 7G was classified at the same facility as fly ash 8z1 (Netzsch-Condux Mahltechnik GmbH), but only once to remove fine particles. No secondary classification was performed to remove coarse particles. The particle size distribution of fly ash 7G was determined using a Cilas 1064 particle size analyzer and is listed in Table 4 below. The PSD of the control fly ash is included for comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com