A water separator and a fuel cell

A fuel cell and water separator technology, applied in the directions of fuel cells, chemical instruments and methods, circuits, etc., can solve the problems of unfavorable water separation device layout integration applicability and system volume power density, fixed water separator size, affecting fuel cells. performance and other issues, to achieve the effect of avoiding the performance degradation of the stack, high layout integration adaptability, and good water separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

[0056] The first specific embodiment of the present invention provides a water separator.

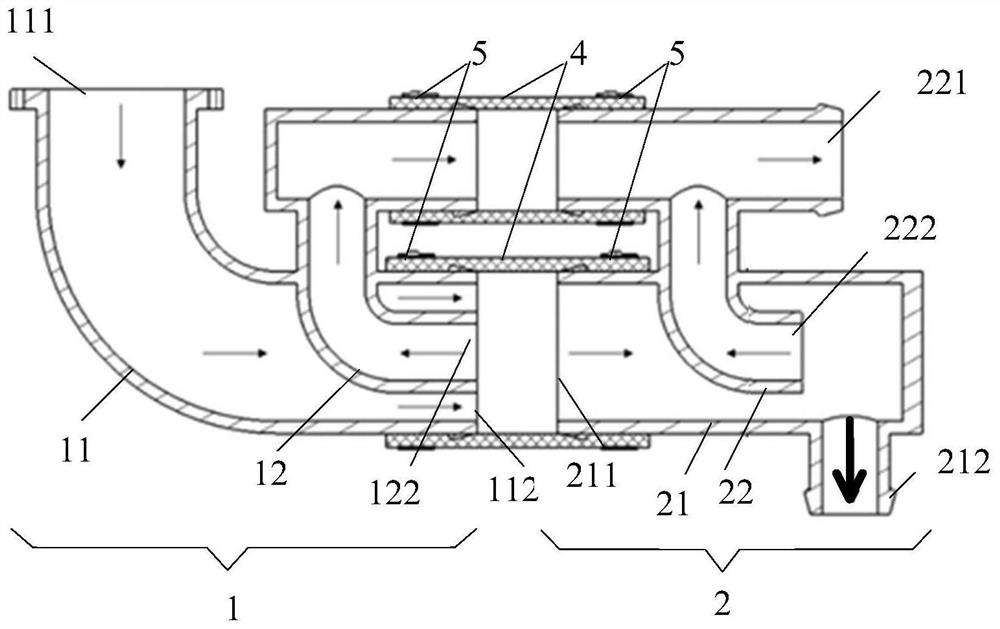

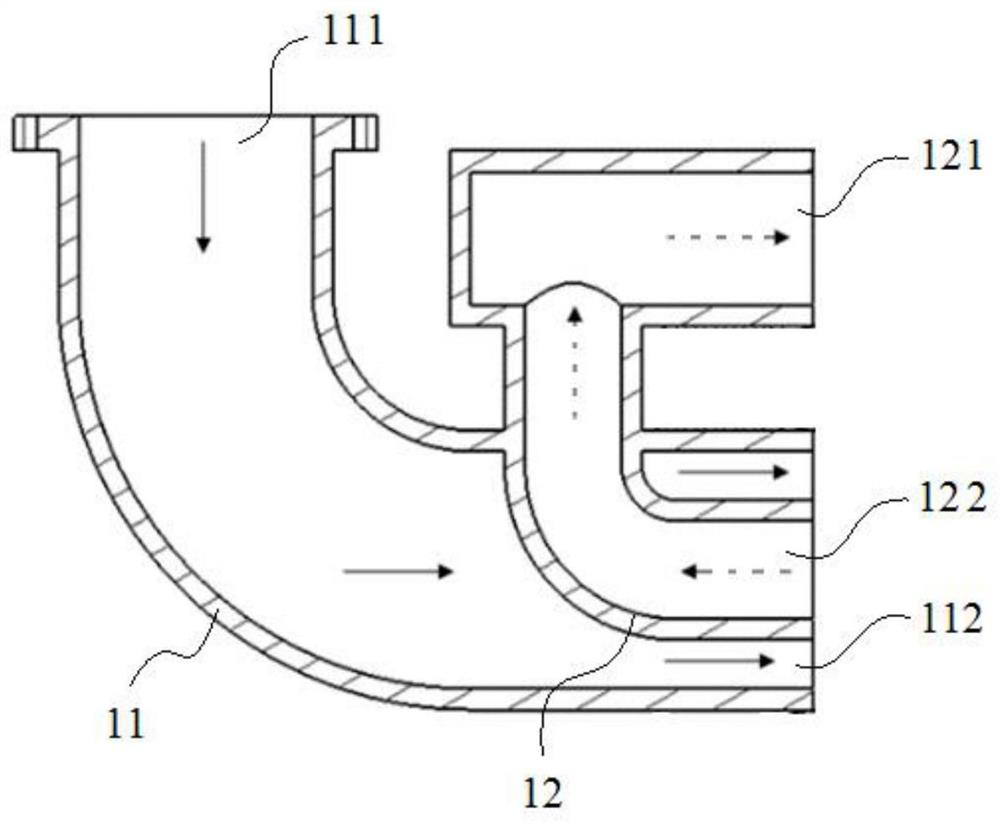

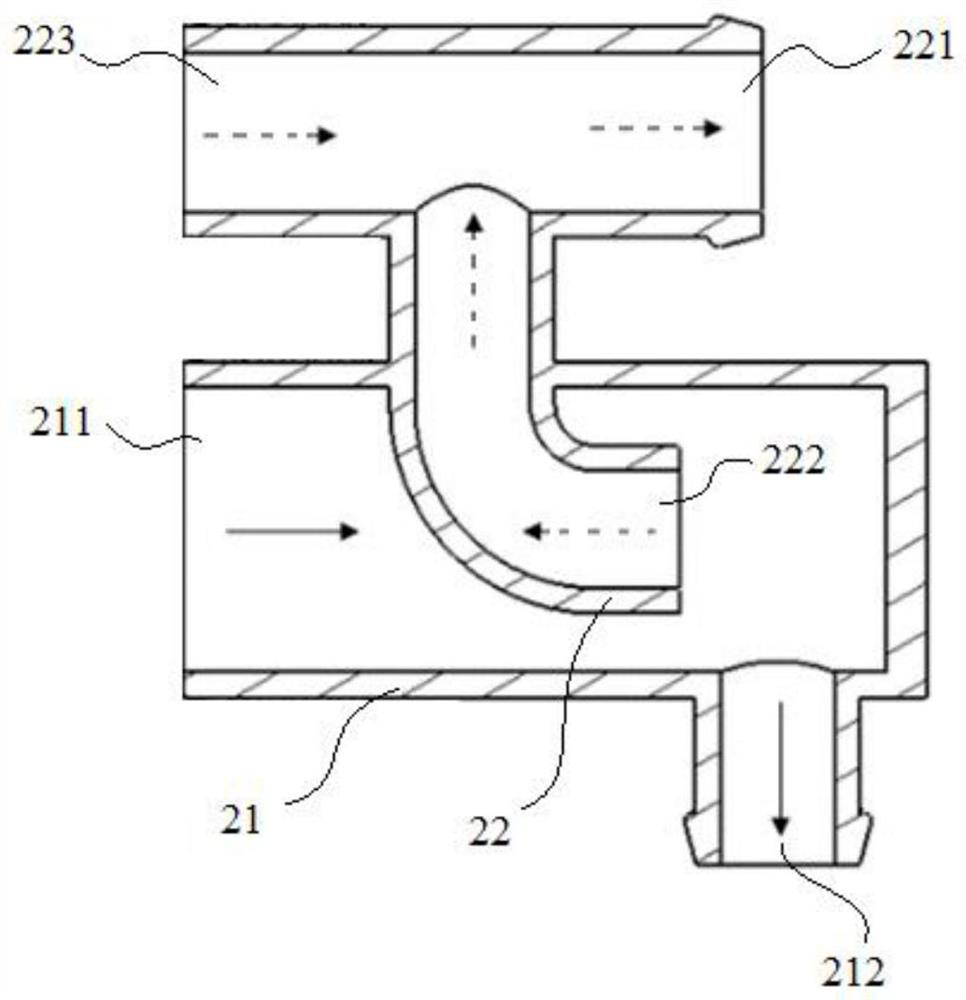

[0057] see Figure 1 to Figure 3 , figure 1 A cross-sectional view of the water separator provided for the first specific embodiment of the present invention; figure 2 A sectional view of the first water diversion section provided for the first specific embodiment of the present invention; image 3A cross-sectional view of the water diversion section at the tail provided for the first specific embodiment of the present invention.

[0058] The water separator provided by the first specific embodiment of the present invention includes a first water diversion section 1 and a tail water diversion section 2, wherein:

[0059] a) The head water diversion section 1 includes the head main flow pipe 11 and the head drainage pipe 12 . Both ends of the head main flow pipe 11 are respectively provided with a mixed fluid inlet 111 and a head fluid outlet 112 . The first drainage pipe 12 includ...

no. 2 Embodiment

[0079] The second specific embodiment of the present invention provides a water separator.

[0080] see Figure 4 to Figure 6 , Figure 4 A cross-sectional view of the water separator provided for the second specific embodiment of the present invention; Figure 5 A cross-sectional view of the middle water-cutting section provided for the second specific embodiment of the present invention; Figure 6 It is a schematic diagram of the overall structure of the water separator provided in the second specific embodiment of the present invention.

[0081] The only difference between the water separator provided by the second specific embodiment of the present invention and the water separator provided by the first specific embodiment of the present invention is that the water separator provided by the second specific embodiment of the present invention is different from that provided by the first specific embodiment. On the basis of the water separator, an intermediate water diver...

no. 3 Embodiment

[0088] The third specific embodiment of the present invention provides a water separator.

[0089] The difference between the water separator provided by the third specific embodiment of the present invention and the water separator provided by the second specific embodiment of the present invention is only that: a plurality of intermediate water diversion sections are arranged in series in sequence, and the middle of the multiple intermediate water diversion sections The main flow pipes are connected at the ends in sequence, and the connecting pipe sections in the multiple intermediate water diversion sections are connected at the ends in sequence. For details, see Figure 4 , the water separator provided by the third specific embodiment of the present invention, in Figure 4On the basis of this, multiple intermediate water diversion sections 3 are arranged in parallel.

[0090] Wherein, in the middle water diversion section 3 at the head end, the middle fluid inlet 311 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com