Low-VOC easy-to-offset-printing cold wave release layer coating and preparation method thereof

A technology of offset printing cold stamping and release layer, which is applied to polyester coatings, coatings, etc., can solve the problems of unstable peeling performance, large film breaking force, and poor offset printing performance, and achieve good peeling performance, simple production process, and easy production The effect of low process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

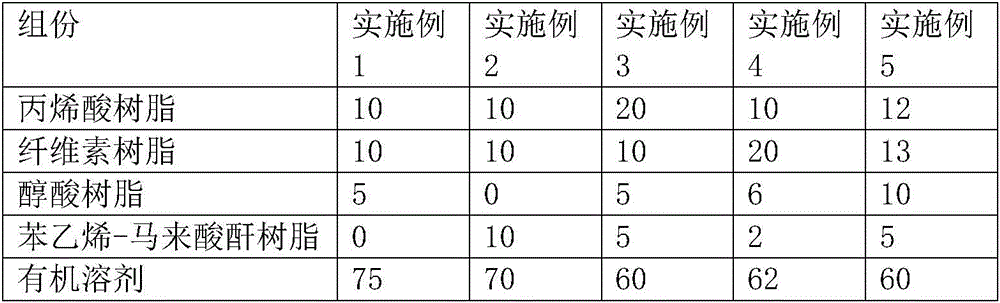

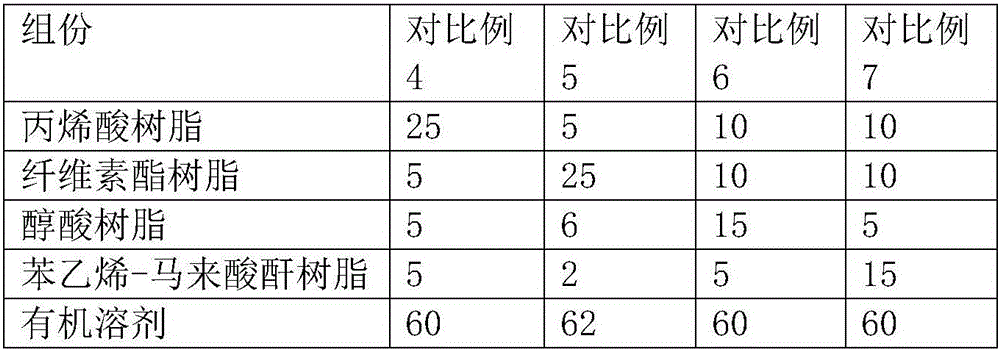

[0036] The present examples 1-5 relate to a kind of low-VOC easy offset cold ironing release layer coating, which is a water-based laser anodized aluminum coating without a release layer, and its preparation specifically includes the following steps:

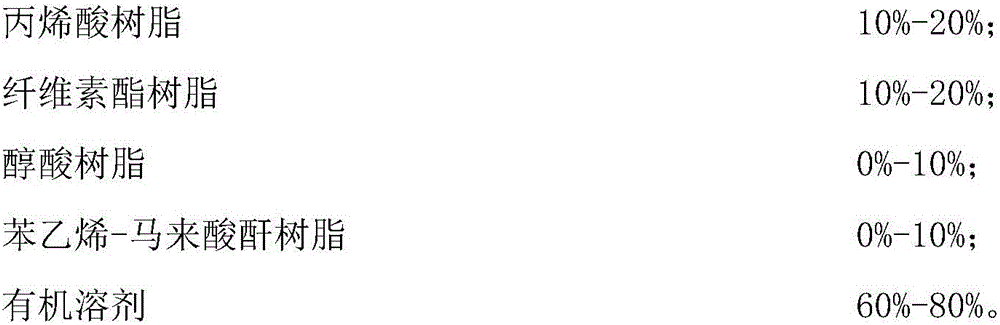

[0037] (1) prepare materials according to the (weight parts) raw materials of each component and content in the following table 1;

[0038] Table 1

[0039]

[0040] (2) Add the organic solvent into the reaction kettle, turn on the mixer to a medium speed of 750-800 rpm, and keep the temperature at 40°C-80°C;

[0041] (3) Add acrylic resin, alkyd resin, styrene-maleic anhydride resin, stir at a high speed of 1000-1200 rpm, and keep stirring at a constant temperature of 40°C-80°C for 40 minutes;

[0042] (4) Add cellulose ester resin, stir at a high speed of 1000-1200 rpm at a constant temperature of 40°C-80°C for 40 minutes, and filter through a 250-320 mesh filter to obtain the low-VOC easy-offset cold-ironing release layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com