Feeding device for warp rebeaming machine

A technology of parallel shaft machine and cross bar, which is applied to cranes, transportation and packaging, trolley cranes, etc., can solve the problems of potential safety hazards, inconvenient feeding, low work efficiency, etc., and achieves low production process requirements and simple structure. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

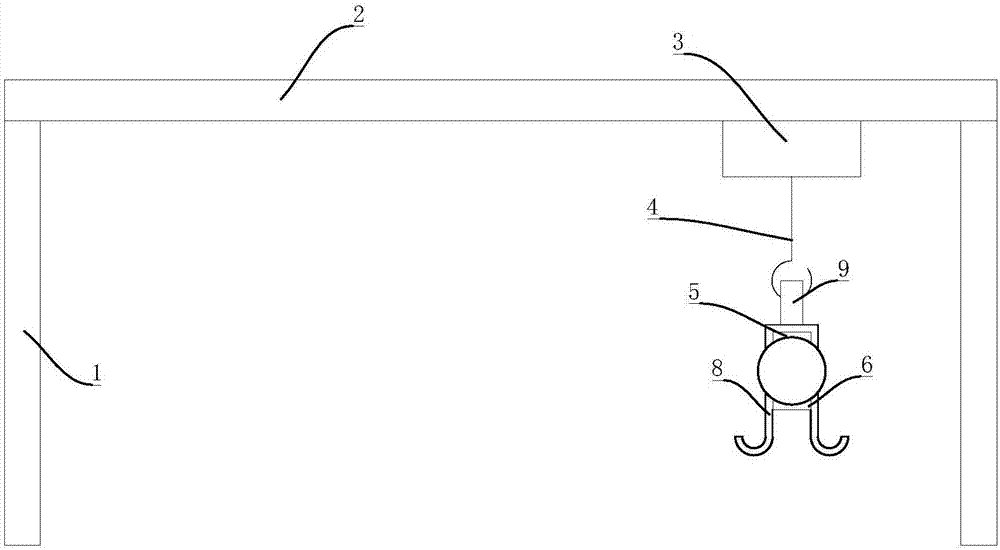

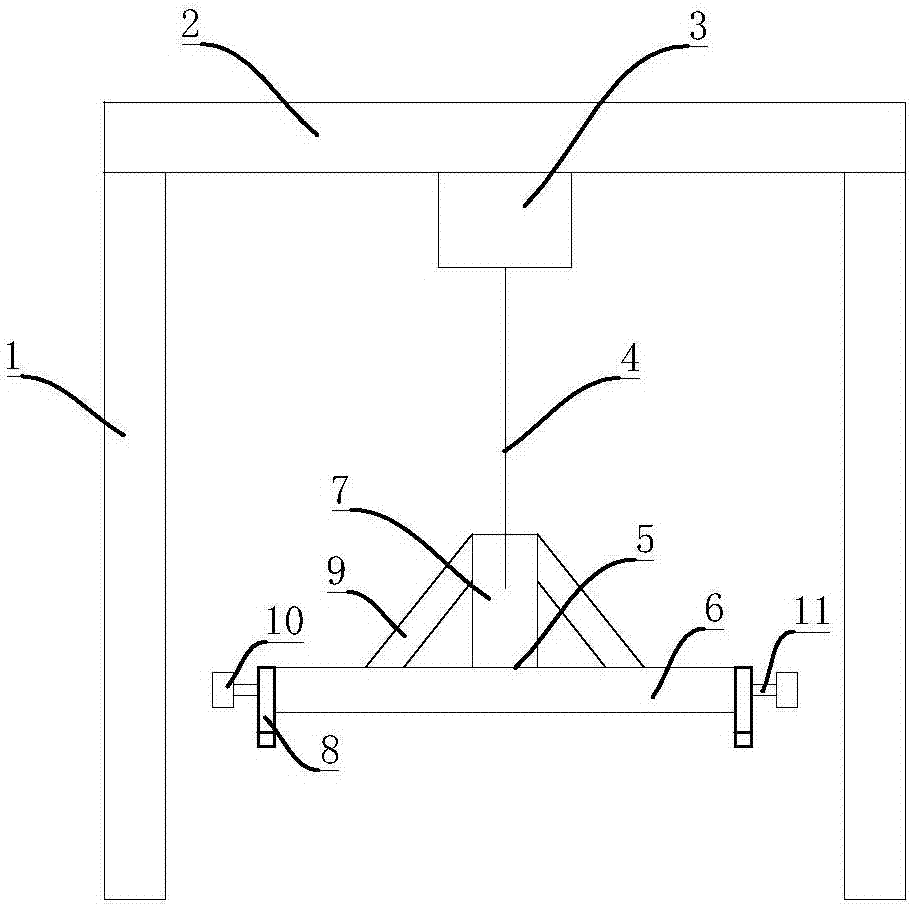

[0017] Such as Figure 1-3 As shown, a feeding device for a parallel shaft machine includes four vertical bottom brackets 1, an I-shaped top bracket 2, and a crane 3 arranged on the top bracket 2. The hook 4 of the crane 3 A hanger 5 is hung on it, and the hanger 5 includes a horizontal bar 6, and a vertical bar 7 fixed above the middle of the bar 6, and the vertical bar 7 is provided with a hanger that matches the hook 4. Hook holes, the two ends of the cross bar 6 are respectively welded with a "several"-shaped hook 8, and the cross bar 6 is embedded in the bottom groove of the hook 8.

[0018] The hook 8 is formed by bending a steel bar, and the two ends are tilted upwards. The hanger 5 is symmetrically welded with reinforcing rods 9 on both sides of the vertical rod 7, and the two ends of the reinforcing rod 9 are connected with the vertical rod 7 and the vertical rod 7 respectively. Cross bar 6 is connected, and the two ends of described cross bar 6 are respectively prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com