Method and system for preparing dynamic lithium ion battery diaphragm

A technology of lithium-ion battery and subsystem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

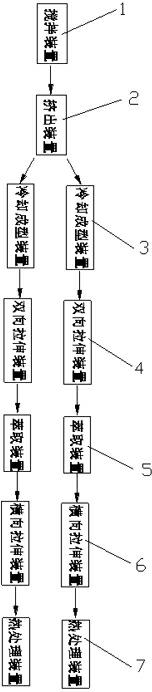

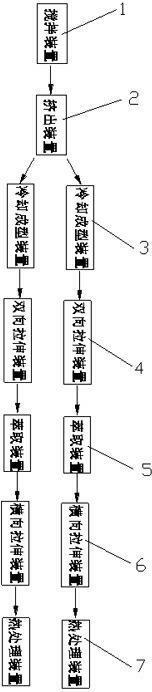

[0055] The invention provides a method for preparing a power lithium-ion battery diaphragm, comprising the following steps:

[0056] 1. Add ultra-high molecular polyethylene, antioxidant and mineral oil into the mixer in a certain proportion to fully stir the raw materials;

[0057] 2. Put the mixture stirred in step 1 into a twin-screw extruder to heat and extrude continuously to form a substrate;

[0058] 3. The substrate extruded from the twin-screw extruder is divided into the first processing line and the second processing line for simultaneous processing;

[0059] 4. Processing of substrates entering the first processing line:

[0060] (1) The substrate entering the first processing line is cooled and formed by a set of cooling rollers;

[0061] (2) Stretch the cooled and formed substrate in both horizontal and vertical directions simultaneously through biaxial stretching equipment, so that the substrate can be stretched into a diaphragm;

[0062] (3) Use an alkane extr...

Embodiment 1

[0072] Embodiment 1, the steps of a lithium-ion battery diaphragm preparation method in this embodiment are as follows:

[0073] 1. Add ultra-high molecular weight polyethylene, antioxidant and mineral oil into the mixer in a certain proportion to fully stir the raw materials. Among them, the mass ratio of mineral oil to antioxidant is 1000~2000:1, mineral oil and The mass ratio of UHMWPE is 2~10:1.

[0074] The ultrahigh molecular weight polyethylene in this example has a molecular weight of 1 million or more.

[0075] 2. Put the mixture stirred in step 1 into a twin-screw extruder to heat and extrude continuously to form a substrate.

[0076] Here, the screw diameter of the twin-screw extruder is 10-150 mm, and its extrusion capacity is greater than 200 kg per hour.

[0077] 3. The substrate extruded from the twin-screw extruder is divided into the first processing line and the second processing line for simultaneous processing.

[0078] 4. Processing of substrates enteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com