Circulating comprehensive utilization technology and system for white wine-making cooling water and bottle washing water

A cooling water and water circulation technology, applied in cleaning methods and utensils, neutralized water/sewage treatment, ion-exchanged water/sewage treatment, etc. The effect of scaling and corrosion mitigation, stabilizing the quality of raw wine, and saving drinking water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific embodiment and accompanying drawing

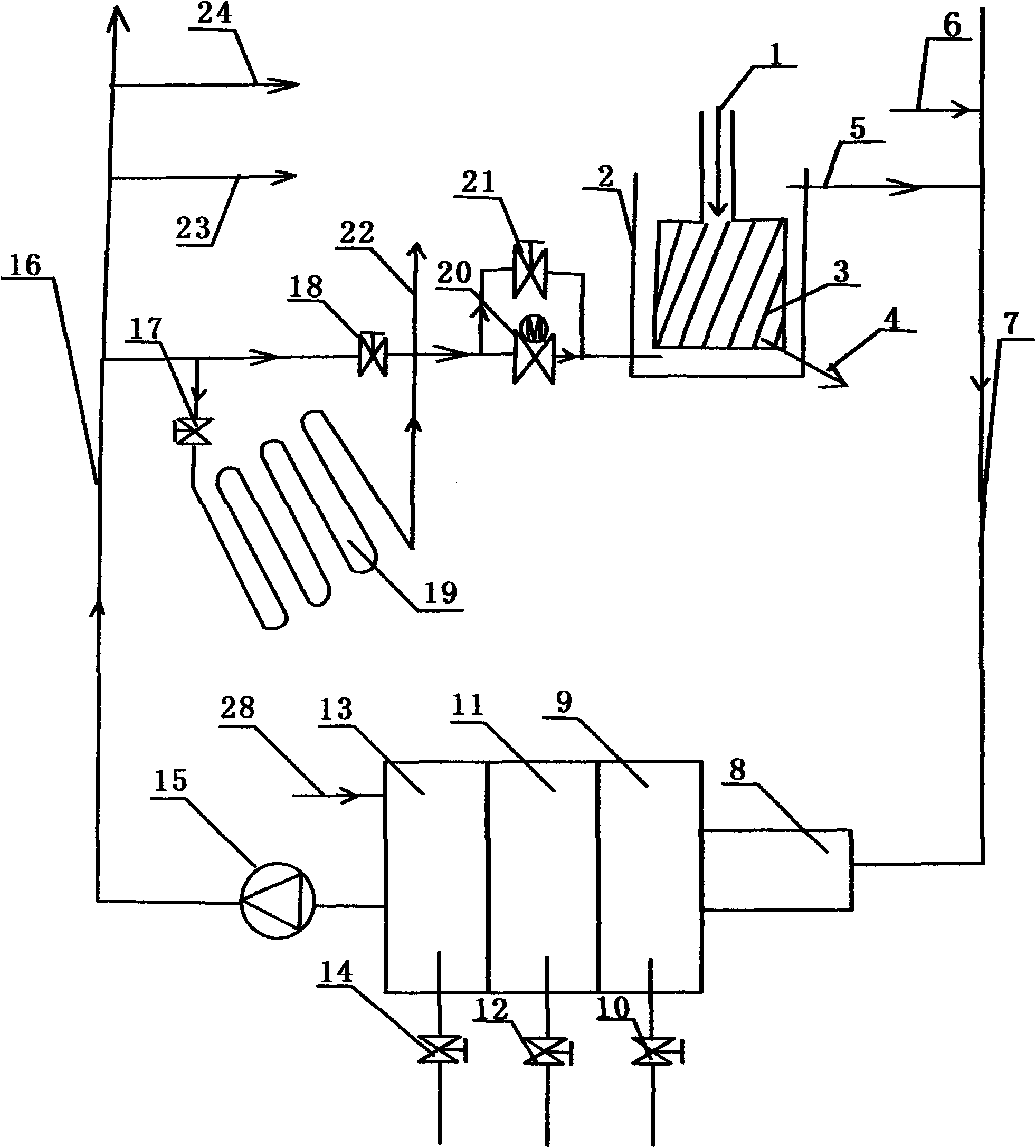

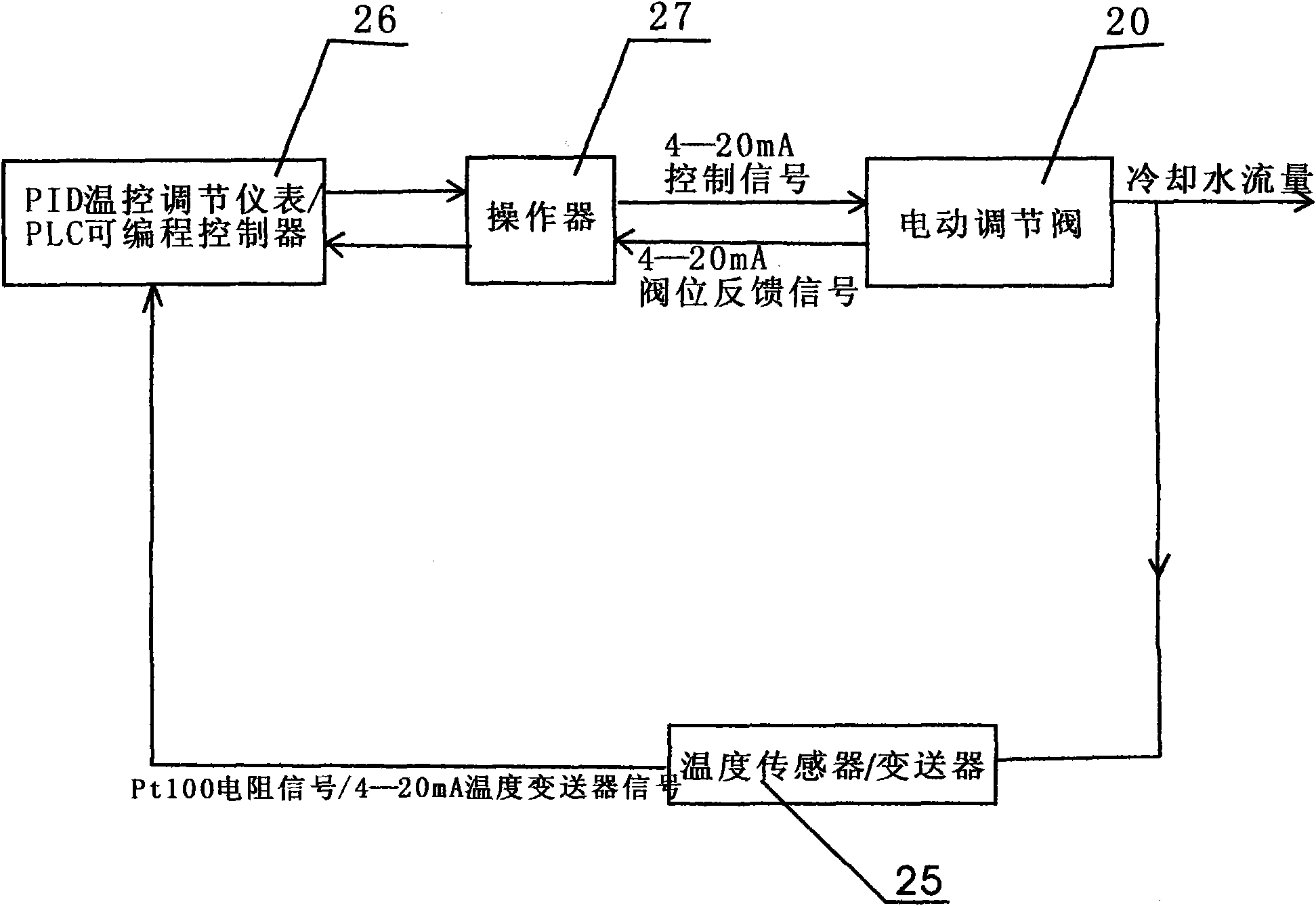

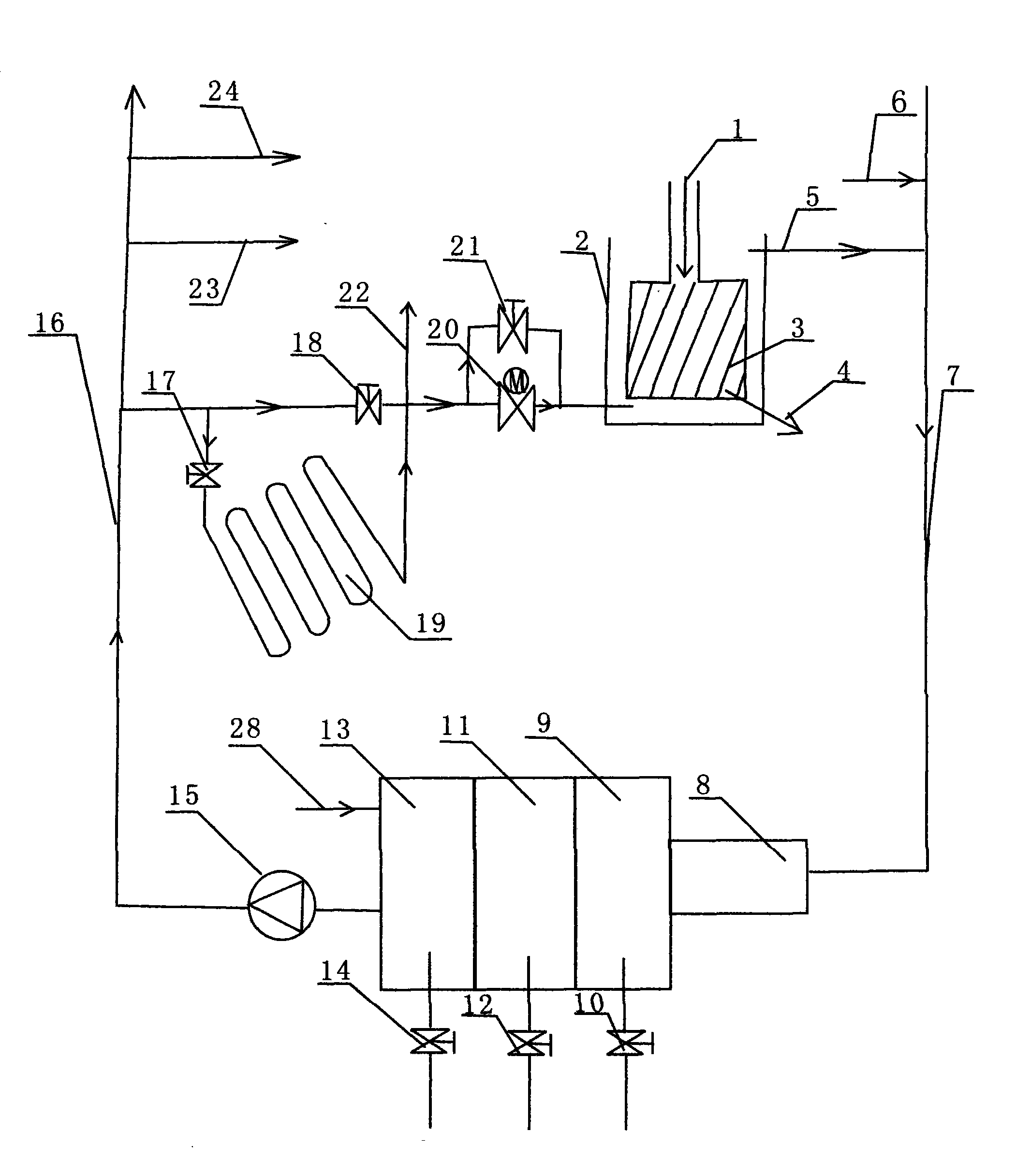

[0037] Liquor cooling water and bottle washing water circulation comprehensive utilization process and its system, including special water supply and drainage circulation system pipeline network and circulating water treatment system for wine cooling water and bottle washing water, automatic control of wine receiving temperature and automatic adjustment technology system of cooling water flow, summer The cooling water used for brewing is too high in natural environment-friendly cooling method, scale control method, corrosion control method, microorganism and slime control method. It is characterized in that: the comprehensive utilization system of wine-making cooling water and bottle-washing water is composed of distilled and vaporized wine inlet 1, bucket-2, condenser-3, liquid raw wine outlet pipeline 4, floating water outlet pipeline 5, bottle-washi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com