Stepless speed-changing device

A continuously variable transmission device and bevel wheel technology, which is applied in the direction of transmission devices, belts/chains/gears, mechanical equipment, etc., can solve the problems of increasing manufacturing costs and energy consumption, high performance and manufacturing process requirements, and large device size and weight and other problems, to achieve the effect of reducing the length and weight of the cone, saving the space for the action to be displayed, and reducing the requirements for the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

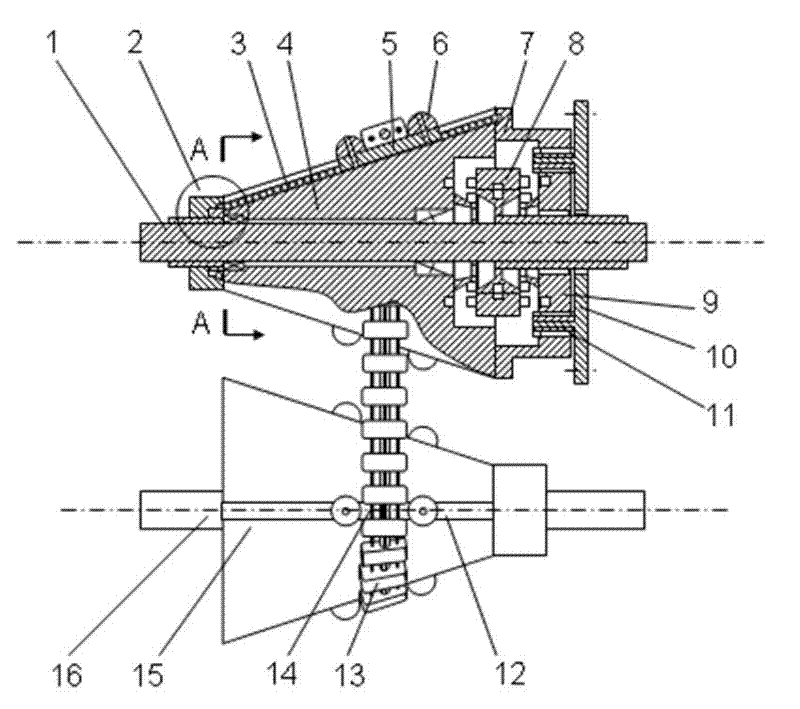

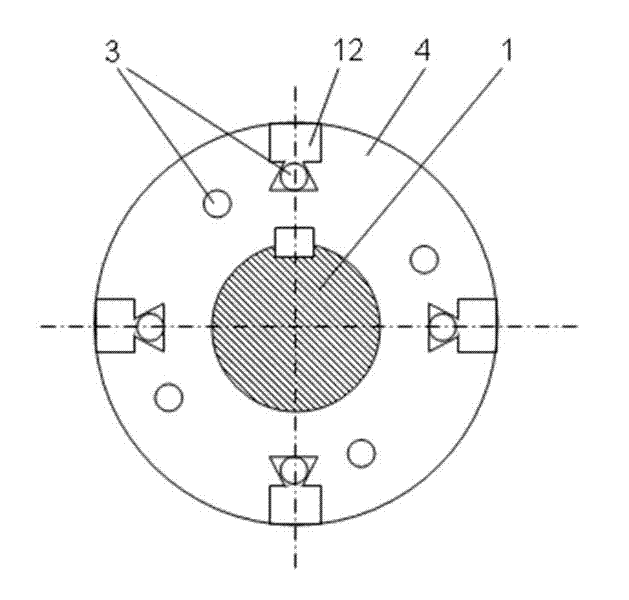

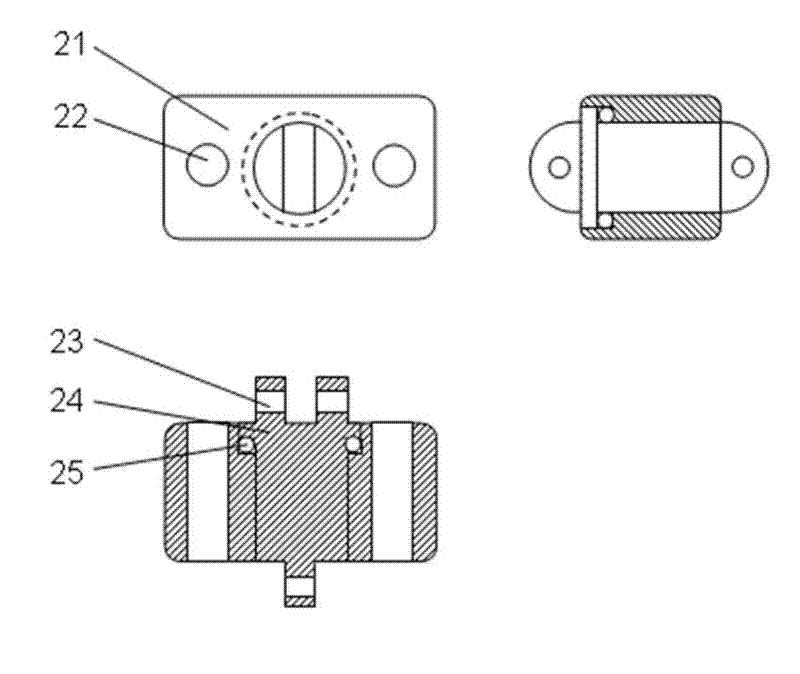

[0021] refer to figure 1 The overall structure shown, figure 2 As shown in the A-A direction view, the input shaft 16 is placed in parallel with the output shaft 1; the input shaft 16 is fixedly connected to the input cone wheel 15, and the output shaft 1 is connected to the output cone wheel 4 in rotation; the input cone wheel 15 and the output cone wheel 4 have conical surfaces In the opposite direction, there are several chutes 12 distributed along the direction of the busbar on the upper side, and each chute has a variable-diameter slider 5 with stoppers 6 at both ends; the transmission chain 13 is placed perpendicular to the input shaft 16, from the variable-diameter slide Pass between the block 6 at block 5 two ends. The drive chain 13 consists of image 3 The unit structure shown is composed of components such as tilting block 21 and roller 25; the chain cores 24 are connected end to end, and are connected by rotating pins at the pin holes 23 at the head and tail to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com