Solvent-free polyurethane joint coating anticorrosive paint for pipelines

A solvent-free polyurethane and anti-corrosion coating technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve the problems of difficult cathodic stripping resistance and low reactivity of polyurethane joint coatings, and achieve good durability Cathodic stripping performance and hot water resistance adhesion performance, excellent performance, effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

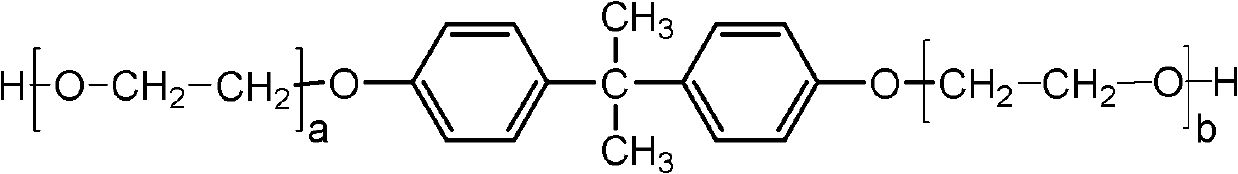

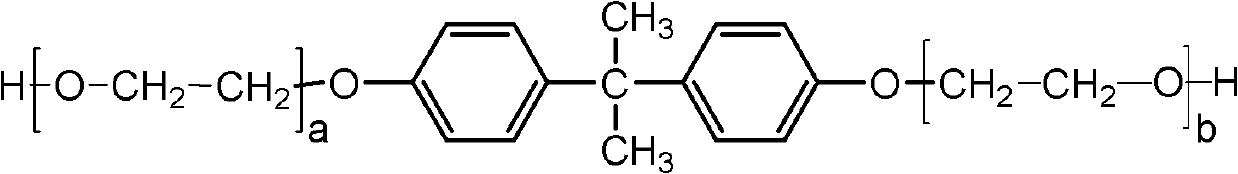

Method used

Image

Examples

Embodiment 1

[0025] Example 1. This example consists of A component and B component. The ratio of component A is: in 100% by weight, polyols with an average equivalent weight of 240 account for 24%, polyols with an average equivalent weight of 800 account for 16%, dispersants account for 0.5%, defoamers account for 0.5%, and Water agent accounts for 5%, dustproof agent accounts for 0.5%, coupling agent accounts for 0.5%, ammonia accelerator accounts for 0.8%, antirust pigment zinc phosphate accounts for 15%, titanium dioxide accounts for 8%, mica powder accounts for 11%, sulfuric acid Barium accounted for 18.2%;

[0026] The curing agent of component B (Bayer Desmodur VL curing agent) accounts for 25% of the total weight of component A.

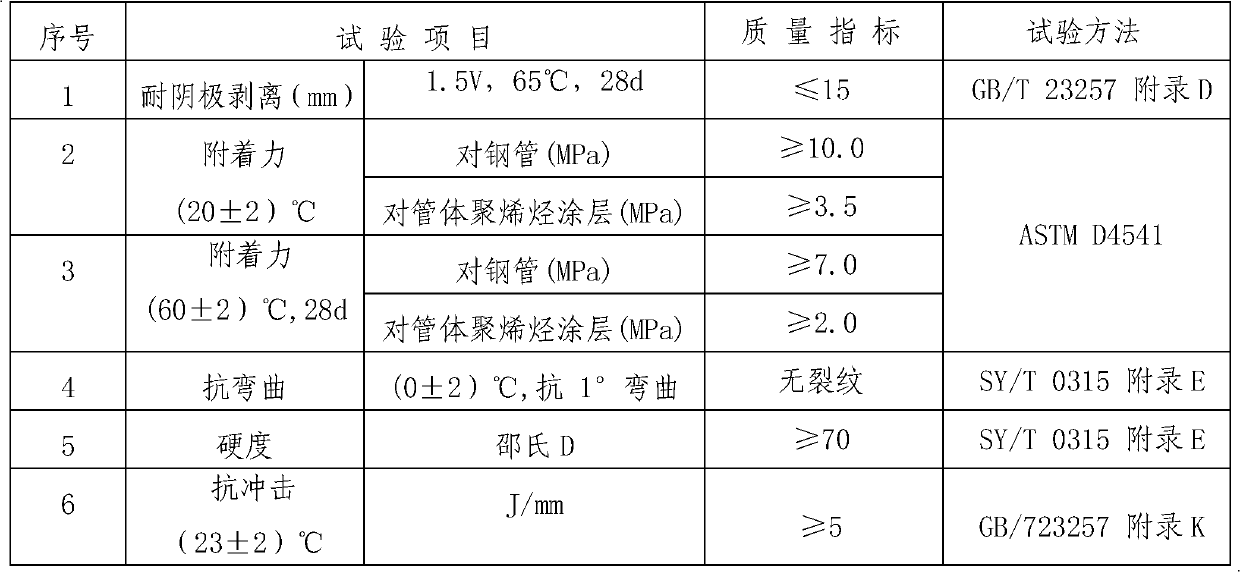

[0027] The performance test results of the materials are shown in Table 2:

[0028] Table 2 Performance test results of solvent-free polyurethane coatings

[0029]

Embodiment 2

[0030] Example 2. This example consists of A component and B component.

[0031] The proportion of component A is that in 100% by weight, polyols with an average equivalent weight of 300 account for 30%, polyols with an average equivalent weight of 1200 account for 12%, dispersants account for 0.3%, defoamers account for 0.8%, and Water agent accounts for 3%, dustproof agent accounts for 0.7%, coupling agent accounts for 0.6%, ammonia accelerator accounts for 0.8%, antirust pigment zinc phosphate accounts for 13%, titanium dioxide accounts for 8%, mica powder accounts for 14%, sulfuric acid Barium accounted for 16.8%;

[0032] The curing agent of component B (Bayer Desmodur VL curing agent) accounted for 28% of the total weight of component A.

[0033] The performance test results of the materials are shown in Table 3:

[0034] Table 3 Performance test results of solvent-free polyurethane coatings

[0035]

[0036]

[0037] After several tests in this example, the coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com