Galvanization-free high-strength and plasticity cold-rolled stainless steel plate for automobile and manufacturing method of galvanization-free high-strength and plasticity cold-rolled stainless steel plate

A technology for cold-rolling stainless steel and stainless steel plate, applied in the field of metallurgy, can solve the problems of low material cost, low formability such as hole expandability and bendability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

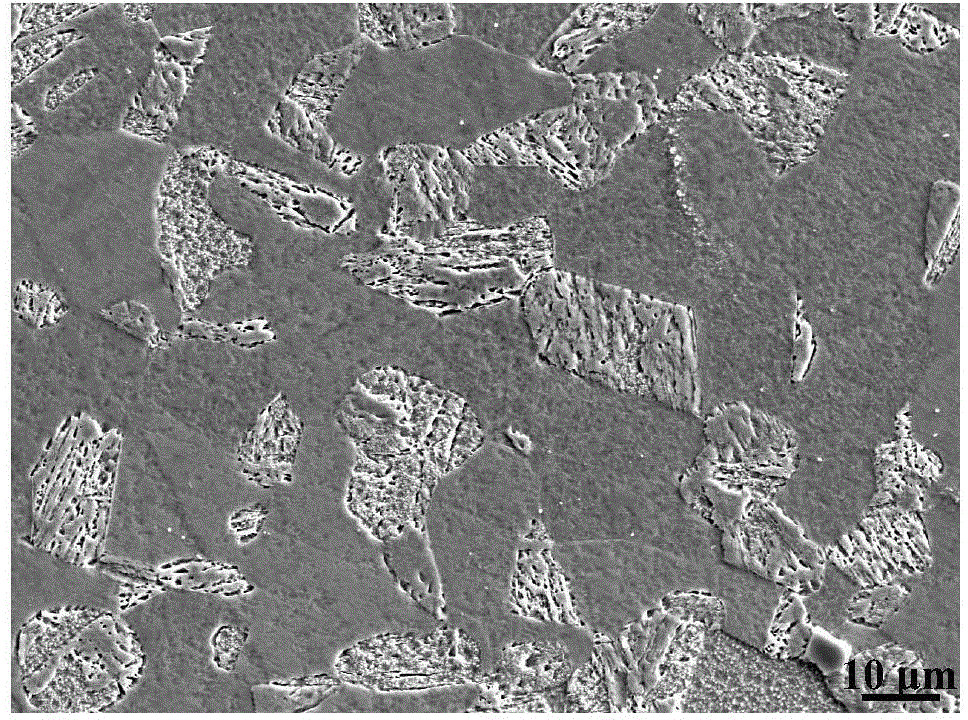

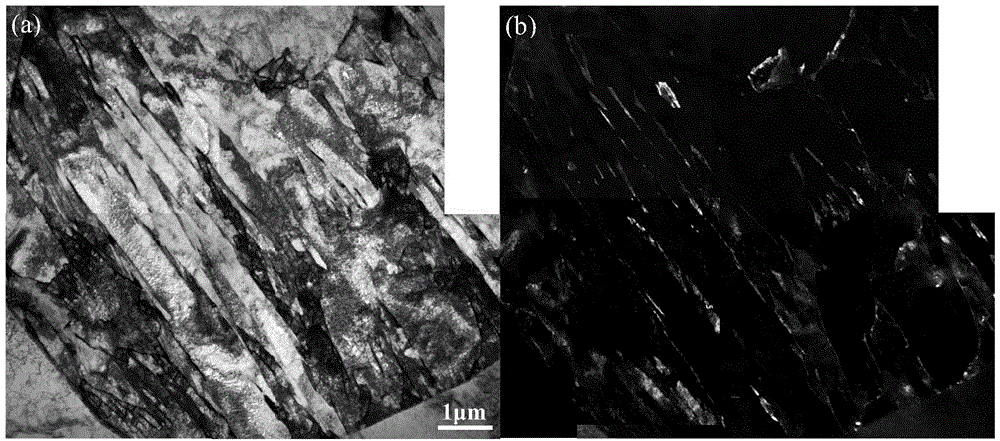

[0089] The manufacturing method of A# steel is: smelting according to the set composition, and casting to make continuous casting slab; the heating temperature of the slab is 1150°C, and the holding time is 1h; the starting temperature of hot rolling is 1100°C, and the finishing temperature is 900°C. The total reduction rate of hot rolling is 92%, and the coiling temperature is 650°C; the annealing temperature of hot-rolled sheet is 950°C, and the holding time is 4min; the total reduction rate of cold rolling is 80%; the austenitization temperature of cold-rolled sheet is 1040°C, hold for 2 minutes, then rapidly cool to 300-380°C at a rate of 80°C / s, then heat to 350-450°C, hold for 2.5-60 minutes, and finally cool to room temperature at a rate of 100°C / s ; The microstructure of A# steel contains ferrite, martensite and retained austenite, in which the volume fraction of ferrite is 65%, the volume fraction of retained austenite is 1-5%, and the rest is martensite body;

[009...

Embodiment 2

[0108] The manufacturing method of B# steel is: smelting according to the set composition, and casting into ingot; the ingot heating temperature is 1100°C, holding time is 1h; The total rolling reduction rate is 92%, and the coiling temperature is 600°C; the hot-rolled sheet annealing temperature is 880°C, and the holding time is 10min; the cold-rolled total reduction rate is 40%; the cold-rolled sheet austenitization temperature is 1040 ℃, the holding time is 2min, then rapidly cooled to 300-400℃ at a rate of 80℃ / s, then heated to 350-450℃, and kept at a temperature of 15-60min, and finally rapidly cooled to room temperature at a rate of 100℃ / s; The microstructure of B# steel contains ferrite, martensite and retained austenite, in which the volume fraction of ferrite is 55%, the volume fraction of retained austenite is 2-8%, and the rest is martensite ;

[0109] The mechanical properties of B# steel are yield strength 391-428MPa, tensile strength 668-702MPa, elongation at br...

Embodiment 3

[0116] The manufacturing method of C# steel is: smelting according to the set composition, and casting to make continuous casting slab; the heating temperature of casting slab is 1200°C, and the holding time is 2h; the starting temperature of hot rolling is 1150°C, and the finishing temperature is 800°C. The total reduction rate of hot rolling is 95%, and the coiling temperature is 500°C; the annealing temperature of hot rolled sheet is 800°C, and the holding time is 8h; the total reduction rate of cold rolling is 75%; the austenitization temperature of cold rolled sheet is 1000°C, holding time is 2min, then rapidly cooling to 100-200°C at a rate of 20°C / s, then heating to 450-575°C, holding for 1-60min, and finally rapidly cooling to room temperature at a rate of 20°C / s ;

[0117]The microstructure of C# steel contains ferrite, martensite and retained austenite, in which the volume fraction of ferrite is 55%, the volume fraction of retained austenite is 2-12%, and the rest is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Strong plastic product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com