Zirconium-based amorphous alloy and preparation method thereof

A technology of zirconium-based amorphous alloys and components, which is applied in the field of amorphous alloy preparation, can solve the problems of poor plasticity of zirconium-based amorphous alloys, and achieve high compressive strength, good application prospects, and simple operation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

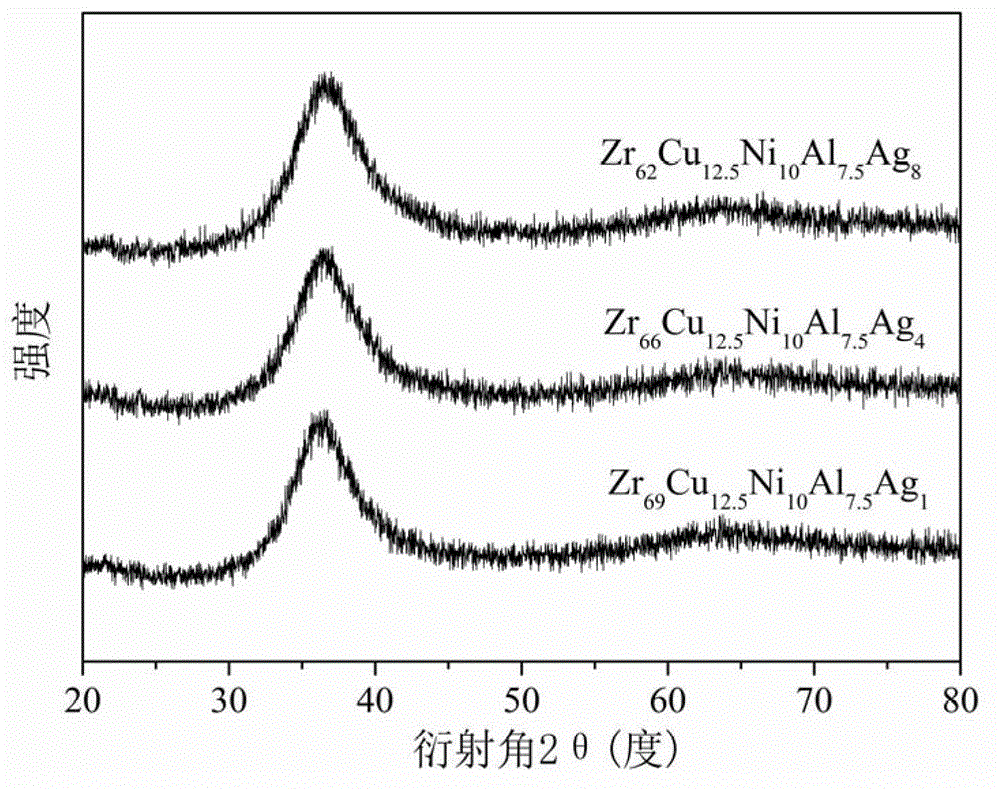

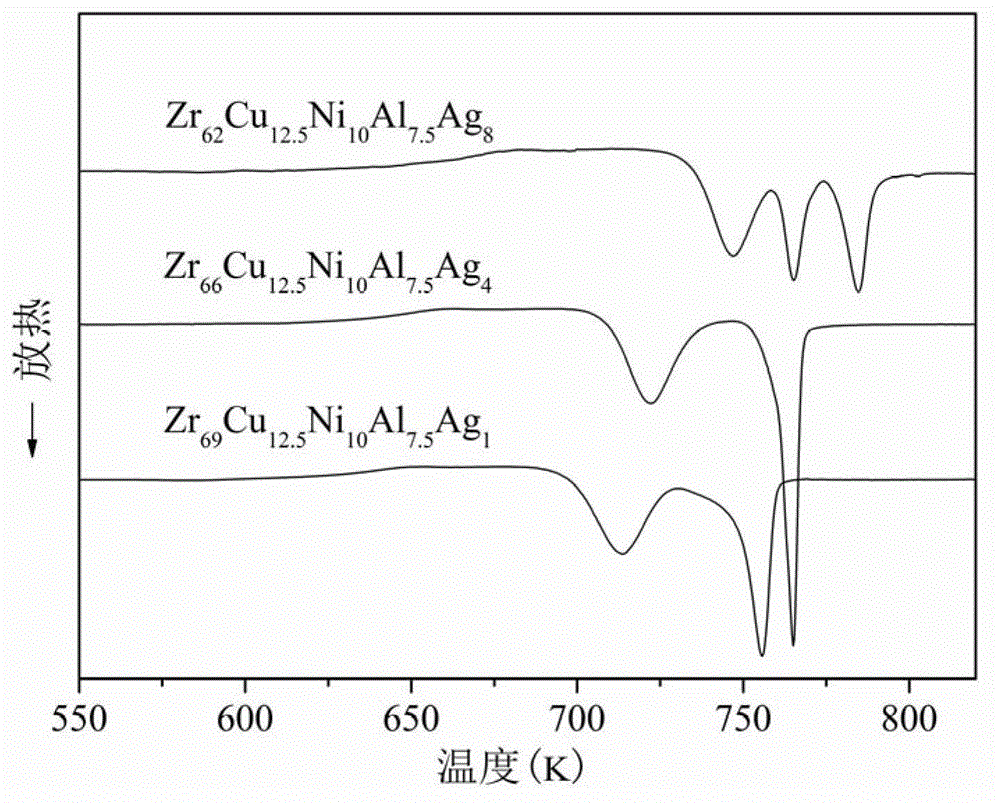

[0037] Preparation of Zr 69 Cu 12.5 Ni 10 Al 7.5 Ag 1 bulk amorphous alloy

[0038] (1) Ingredients: Accurately weigh Zr, Cu, Ni, Al, Ag elemental substances with a purity of not less than 99.9wt% according to the stoichiometric ratio, and mix them evenly.

[0039] (2) Oxygen consumption: in a vacuum of 2×10 -3 Argon with a purity of 99.999% is introduced into the Pa vacuum melting furnace, and then pure titanium is used to consume oxygen in the vacuum melting furnace to remove all the oxygen in the argon atmosphere;

[0040] (3) Melting: Put the mixture obtained in step (1) in the water-cooled copper crucible of the vacuum arc melting furnace described in step (2), and smelt it under the protection of the high-purity argon atmosphere obtained in step (2). The current is 200A, and the time for each smelting is 1min. After the alloy is cooled and solidified, the ingot is turned over with a manipulator, and then the next smelting is carried out, and the smelting is repeate...

Embodiment 2

[0047] Preparation of Zr 68 Cu 12.5 Ni 10 Al 7.5 Ag 2 bulk amorphous alloy

[0048] (1) Ingredients: Accurately weigh Zr, Cu, Ni, Al, Ag elemental substances with a purity of not less than 99.9wt% according to the stoichiometric ratio, and mix them evenly.

[0049] (2) Oxygen consumption: in a vacuum of 2.5×10 -3 Argon with a purity of 99.999% is introduced into the Pa vacuum melting furnace, and then pure titanium is used to consume oxygen in the vacuum melting furnace to remove all the oxygen in the argon atmosphere;

[0050] (3) Melting: Put the mixture obtained in step (1) in the water-cooled copper crucible of the vacuum arc melting furnace described in step (2), and smelt it under the protection of the high-purity argon atmosphere obtained in step (2). The current is 200A, and the time for each smelting is 1min. After the alloy is cooled and solidified, the ingot is turned over with a manipulator, and then the next smelting is carried out, and the smelting is repea...

Embodiment 3

[0053] Preparation of Zr 67 Cu 12.5 Ni 10 Al 7.5 Ag 3 bulk amorphous alloy

[0054] (1) Ingredients: Accurately weigh Zr, Cu, Ni, Al, Ag elemental substances with a purity of not less than 99.9wt% according to the stoichiometric ratio, and mix them evenly.

[0055] (2) Oxygen consumption: in a vacuum of 2×10 -3 Argon with a purity of 99.999% is introduced into the Pa vacuum melting furnace, and then pure titanium is used to consume oxygen in the vacuum melting furnace to remove all the oxygen in the argon atmosphere;

[0056] (3) Melting: Put the mixture obtained in step (1) in the water-cooled copper crucible of the vacuum arc melting furnace described in step (2), and smelt it under the protection of the high-purity argon atmosphere obtained in step (2). The current is 250A, and the time for each smelting is 1min. After the alloy is cooled and solidified, the ingot is turned over with a manipulator, and then the next smelting is carried out, and the smelting is repeate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com