Nickle-based block metal glass and its production

A bulk metal and glass technology, applied in the field of amorphous alloys, can solve the problems of low glass forming ability, complex preparation process, unfavorable practical application, etc., and achieve excellent mechanical properties, high glass transition temperature and crystallization temperature, and inhibit crystallization. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1, prepare Ni 52 co 10 Nb 23 Ta 15 large piece of metallic glass

[0024] The purity of the raw material is 99.9wt% (weight percent) of Ni, Co, Nb, and Ta components in a molar ratio of 52:10:23:15. Mix well in an electric arc furnace with an argon atmosphere adsorbed by titanium And smelting, after cooling to get Ni 52 co 10 Nb 23 Ta 15 Master alloy casting ingot; then use the conventional metal mold casting method to melt the ingot again, and use the suction casting device in the electric arc furnace to suck the master alloy melt into the water-cooled copper mold to obtain the composition of Ni 52 co 10 Nb 23 Ta 15 , a large piece of metallic glass with a diameter of 2 mm.

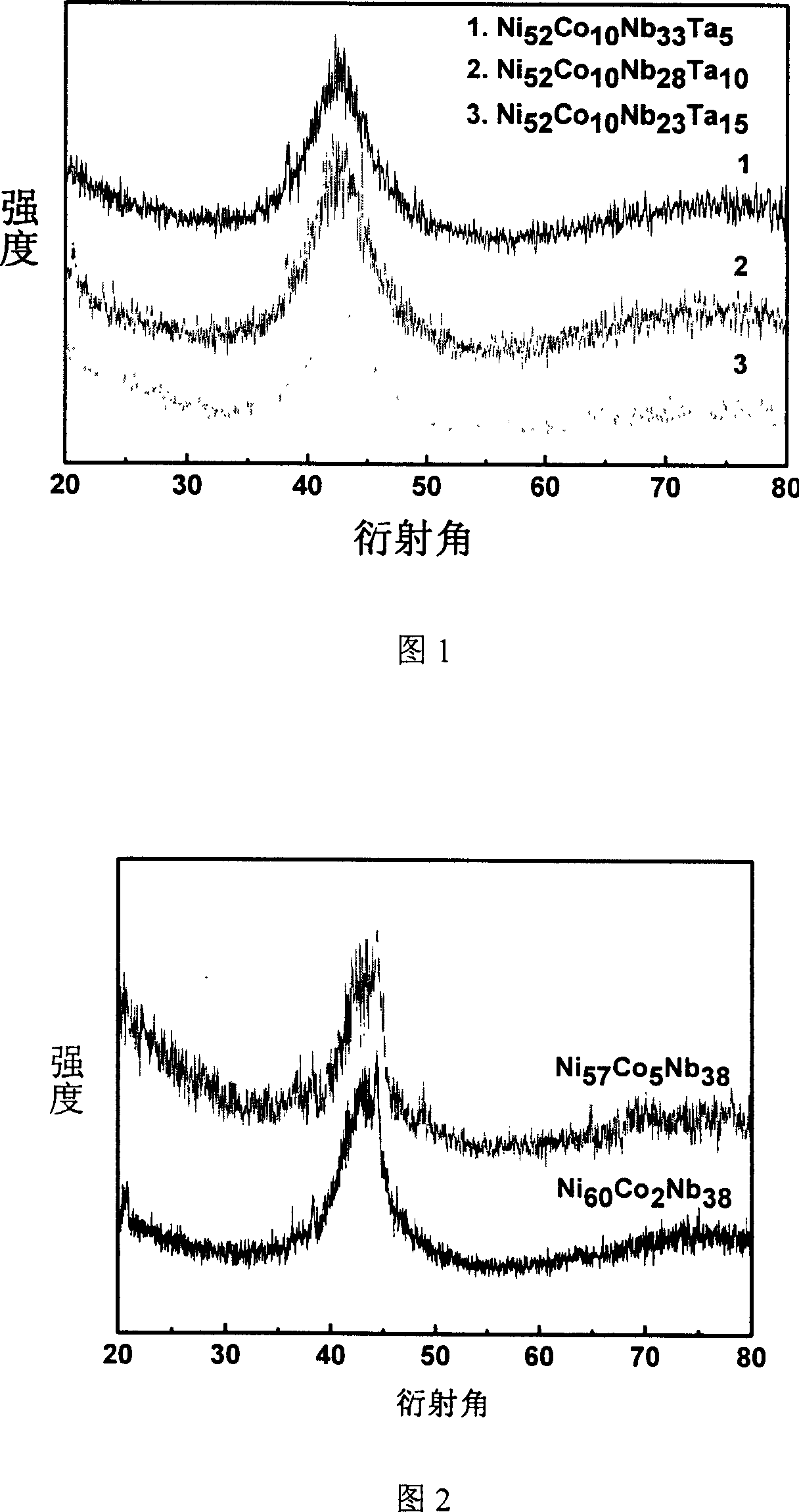

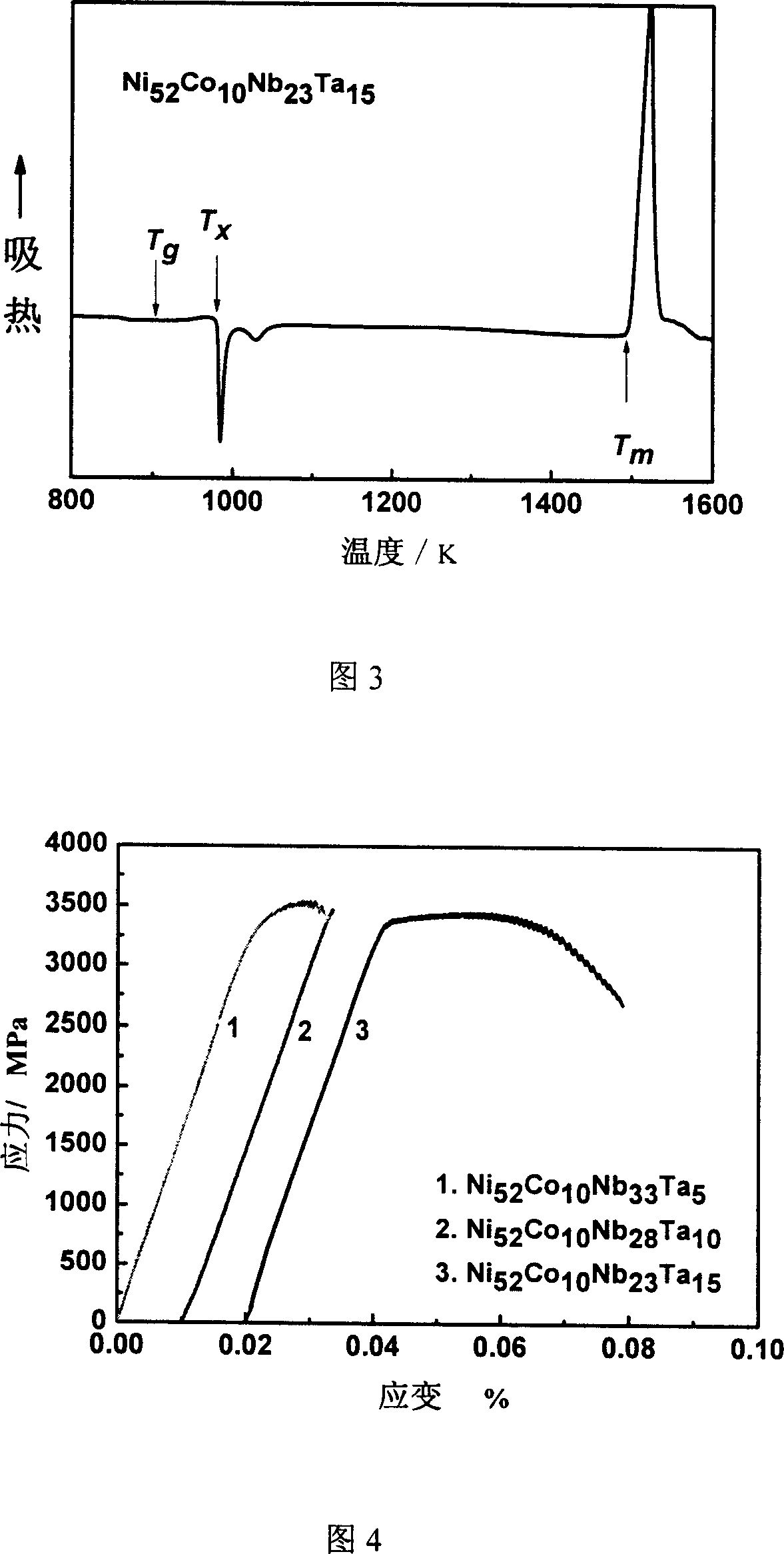

[0025] From the X-ray diffraction (XRD) shown in Figure 1, it can be proved that Ni 52 co 10 Nb 23 Ta 15 The alloy is a completely amorphous alloy. Figure 3 is Ni 52 co 10 Nb 23 Ta 15 Thermal analysis (DSC and DTA) diagrams of bulk amorphous alloys, as can be seen fr...

Embodiment 2~24

[0027] Embodiments 2-24, preparation of various proportions of nickel-based bulk metallic glass

[0028] Various proportions of nickel-based bulk metallic glasses were prepared according to the method of Example 1, and their compositions and thermal physical parameters are listed in Table 1.

[0029] Table 1. Composition and thermophysical parameters of various proportioning nickel-based bulk metallic glasses of the present invention

[0030] Reality

apply

example

D.

(mm)

T g

(K)

T x

(K)

T m

(K)

ΔT

T rg

R

(K / min)

1

Ni 52 co 10 Nb 23 Ta 15

2

938

981

1495

43

0.627

20

2

Ni 52 co 10 Nb 3 Ta 35

2

961

998

1519

37

0.632

20

3

Ni 52 co 10 Nb 8 Ta 30

2

955

993

1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com