Galvanized-free high-strength and plastic cold-rolled stainless steel sheet for automobiles and manufacturing method thereof

A technology of stainless steel plate and manufacturing method, which is applied in the field of metallurgy, and can solve the problems of low formability, low material cost, etc., such as hole expansion and bending properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

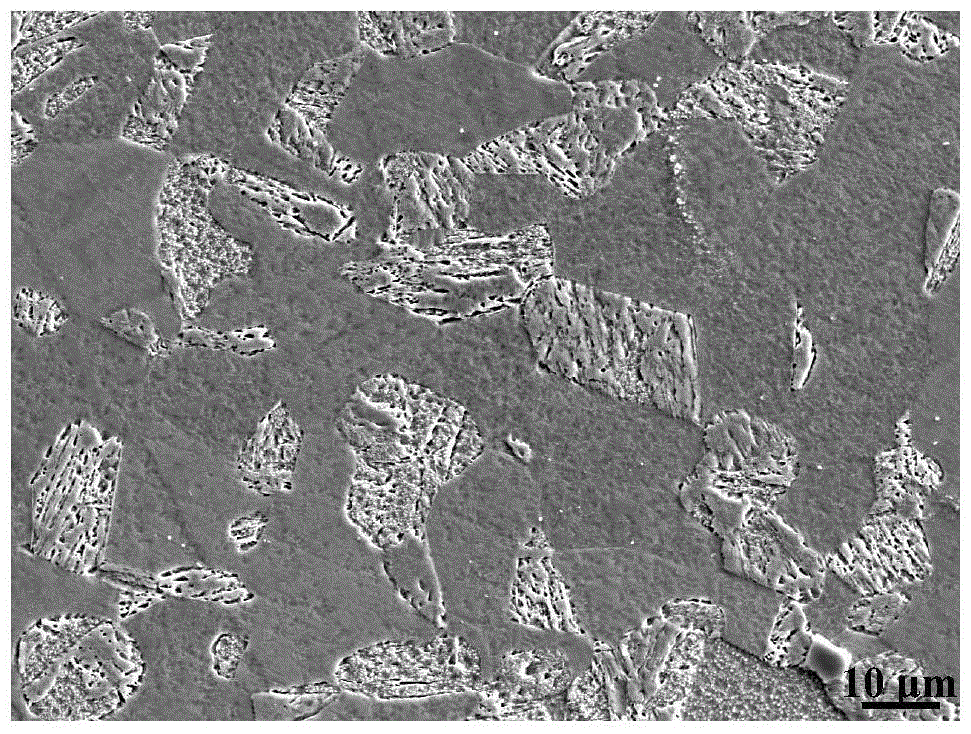

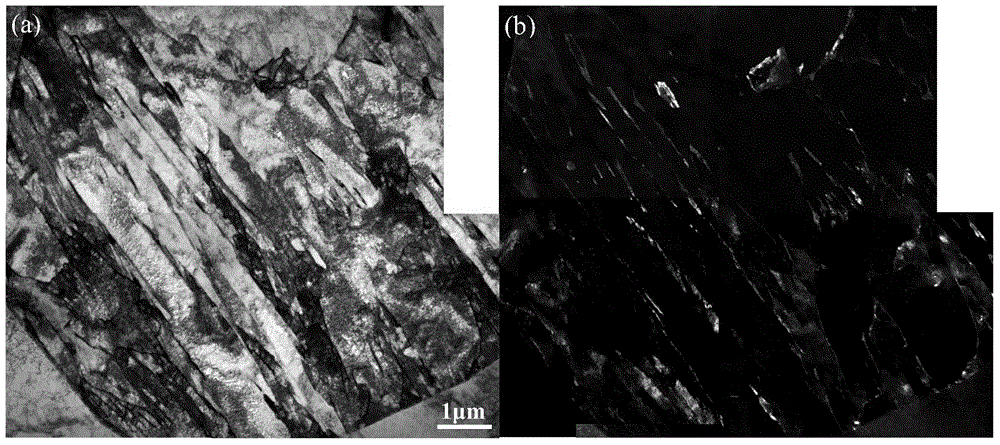

[0089] The manufacturing method of A# steel is: smelting according to the set composition, and casting to make continuous casting slab; the heating temperature of the slab is 1150°C, and the holding time is 1h; the starting temperature of hot rolling is 1100°C, and the finishing temperature is 900°C. The total reduction rate of hot rolling is 92%, and the coiling temperature is 650°C; the annealing temperature of hot-rolled sheet is 950°C, and the holding time is 4min; the total reduction rate of cold rolling is 80%; the austenitization temperature of cold-rolled sheet is 1040°C, hold for 2 minutes, then rapidly cool to 300-380°C at a rate of 80°C / s, then heat to 350-450°C, hold for 2.5-60 minutes, and finally cool to room temperature at a rate of 100°C / s ; The microstructure of A# steel contains ferrite, martensite and retained austenite, in which the volume fraction of ferrite is 65%, the volume fraction of retained austenite is 1-5%, and the rest is martensite body;

[009...

Embodiment 2

[0108] The manufacturing method of B# steel is: smelting according to the set composition, and casting into ingot; the ingot heating temperature is 1100°C, holding time is 1h; The total rolling reduction rate is 92%, and the coiling temperature is 600°C; the hot-rolled sheet annealing temperature is 880°C, and the holding time is 10min; the cold-rolled total reduction rate is 40%; the cold-rolled sheet austenitization temperature is 1040 ℃, the holding time is 2min, then rapidly cooled to 300-400℃ at a rate of 80℃ / s, then heated to 350-450℃, and kept at a temperature of 15-60min, and finally rapidly cooled to room temperature at a rate of 100℃ / s; The microstructure of B# steel contains ferrite, martensite and retained austenite, in which the volume fraction of ferrite is 55%, the volume fraction of retained austenite is 2-8%, and the rest is martensite ;

[0109] The mechanical properties of B# steel are yield strength 391-428MPa, tensile strength 668-702MPa, elongation at br...

Embodiment 3

[0116] The manufacturing method of C# steel is: smelting according to the set composition, and casting to make continuous casting slab; the heating temperature of casting slab is 1200°C, and the holding time is 2h; the starting temperature of hot rolling is 1150°C, and the finishing temperature is 800°C. The total reduction rate of hot rolling is 95%, and the coiling temperature is 500°C; the annealing temperature of hot rolled sheet is 800°C, and the holding time is 8h; the total reduction rate of cold rolling is 75%; the austenitization temperature of cold rolled sheet is 1000°C, holding time is 2min, then rapidly cooling to 100-200°C at a rate of 20°C / s, then heating to 450-575°C, holding for 1-60min, and finally rapidly cooling to room temperature at a rate of 20°C / s ;

[0117]The microstructure of C# steel contains ferrite, martensite and retained austenite, in which the volume fraction of ferrite is 55%, the volume fraction of retained austenite is 2-12%, and the rest is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com