Iron-based nanocrystalline magnetically soft alloy material and preparation method thereof

A technology of iron-based nanocrystals and soft magnetic alloys, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of low loss, high cost, and low saturation magnetic induction intensity, and achieve low loss, low cost, and high saturation The effect of magnetic induction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] Simultaneously, the present invention also provides a kind of preparation method of iron-based nanocrystalline soft magnetic alloy, comprising the following steps:

[0053] (1) According to the formula (Fe a Si b B c P d Cu e ) fMgThe atomic content in the preparation alloy raw materials, a, b, c, d, e are the corresponding content of each atom, f, g are the corresponding composition or percentage content of atoms, where 0.75≤a≤0.87, 0

[0054] (2) Put the above-mentioned alloy raw materials in a smelting device for smelting to obtain alloy ingots;

[0055] (3) breaking the alloy ingot obtained in step (2);

[0056] (4) The broken alloy ingot is melted, and the alloy liquid is sprayed onto the rotating copper roller by a single-roll quenching method to prepare an amorphous alloy;

[0057] (5) Carry out cryst...

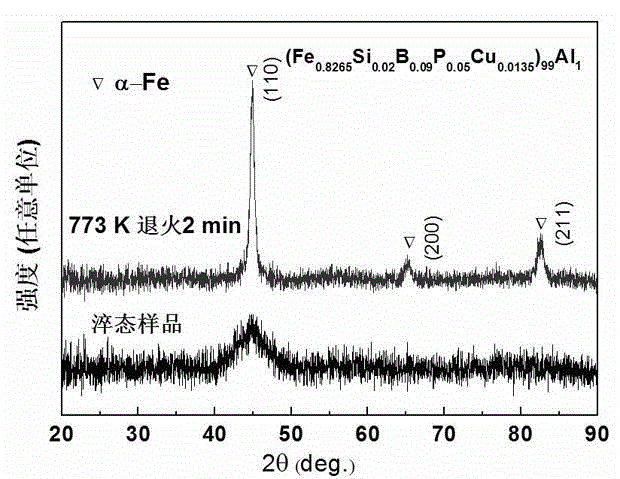

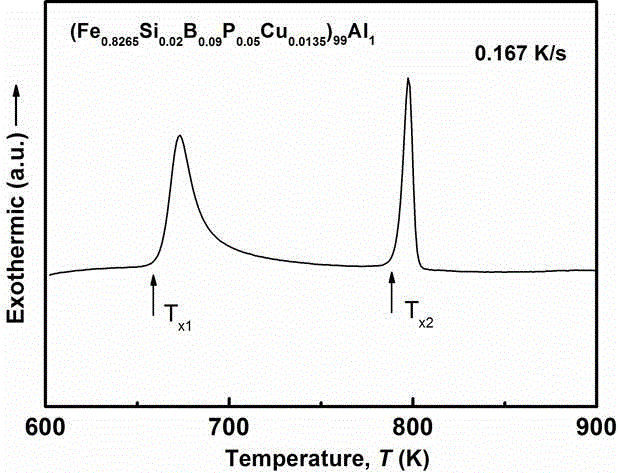

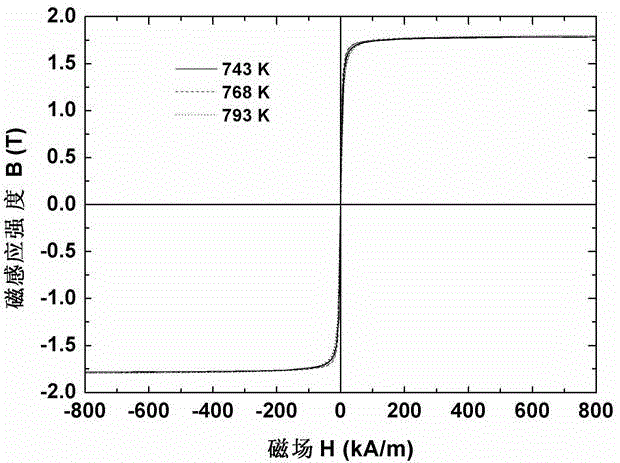

Embodiment 1

[0068] The preparation composition is (Fe 0.8265 Si 0.02 B 0.09 P 0.05 Cu 0.0135 ) 99 al 1 The nanocrystalline soft magnetic alloy, the steps are as follows:

[0069] (1) Using pure Fe, pure Si, pure B, pure Cu, pure Al and Fe-P alloys with a purity greater than 99.5% as raw materials, according to (Fe 0.8265 Si 0.02 B 0.09 P 0.05 Cu 0.0135 ) 99 al 1 Weigh the raw materials according to the ratio and set aside;

[0070] (2) Place the raw materials weighed in step (1) in a high-frequency induction melting furnace for melting, first vacuumize to 4×10 -3 Pa, then filled with argon gas to a pressure of 0.09 MPa for melting, fully smelted after melting, and then kept for 10 minutes, and then poured into the casting mold - copper mold to obtain alloy ingots;

[0071] (3) Remove the surface impurities of the alloy ingot obtained in step (2), then perform ultrasonic cleaning in alcohol, then break the alloy ingot into small alloy ingots, and perform ultrasonic cleaning ...

Embodiment 2

[0082] The preparation composition is (Fe 0.8265 Si 0.02 B 0.09 P 0.05 Cu 0.0135 ) 99 Mo 1 The nanocrystalline soft magnetic alloy, the steps are as follows:

[0083] (1) Using pure Fe, pure Si, pure B, pure Cu, pure Mo and Fe-P alloy with a purity greater than 99.5% as raw materials, according to the molecular formula (Fe 0.8265 Si 0.02 B 0.09 P 0.05 Cu 0.0135 ) 99 Mo 1 Weigh the raw materials according to the ratio and set aside;

[0084] (2) Place the raw materials weighed in step (1) in a high-frequency induction melting furnace for melting, first vacuumize to 4×10 -3 Pa, and then filled with argon until the pressure is 0.09 MPa for smelting, fully smelted after melting, kept for 10 minutes, and then poured into the casting mold - copper mold to obtain alloy ingots;

[0085] (3) Remove the surface impurities of the alloy ingot obtained in step (2), then perform ultrasonic cleaning in alcohol, then break the alloy ingot into small alloy ingots, and perform ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Saturation magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com