Composite soft magnetic material and method for preparing material

A composite soft magnetic and soft magnetic alloy technology, applied in the direction of inorganic material magnetism, metal material coating process, liquid chemical plating, etc. The atmosphere is difficult to take care of other issues at the same time to achieve the effects of good mechanical properties, high magnetic permeability, and high saturation magnetic induction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

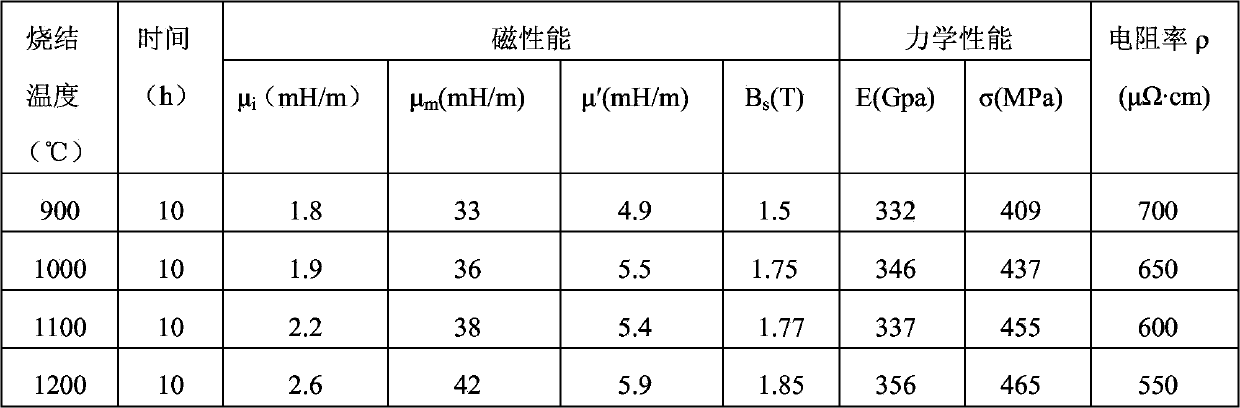

Embodiment 1

[0035] This embodiment mainly includes two steps, the first step, the preparation of the soft magnetic ferrite composite powder that is coated with metal soft magnetic powder: (1) the composition is Mn 0.64 Zn 0.29 Fe 2.07 o 4The soft magnetic ferrite is crushed into powder particles of 30-50μm, and the crushing method is mechanical crushing. First, it is coarsely crushed into small particles of 0.5-2mm, and then ball milling is used. (2) adding the soft magnetic ferrite powder after ball milling into the prepared roughening solution, the composition of the roughening solution is a mixed solution of potassium fluoride and hydrofluoric acid, wherein the concentration of potassium fluoride is 0.3wt%, The concentration of hydrofluoric acid was 1.6 vol%. After ultrasonic oscillation at room temperature for 15 minutes, the powder was taken out, washed with deionized water, and dried in a vacuum drying oven. (3) Put the roughened dry powder into a certain amount of sensitization ...

Embodiment 2

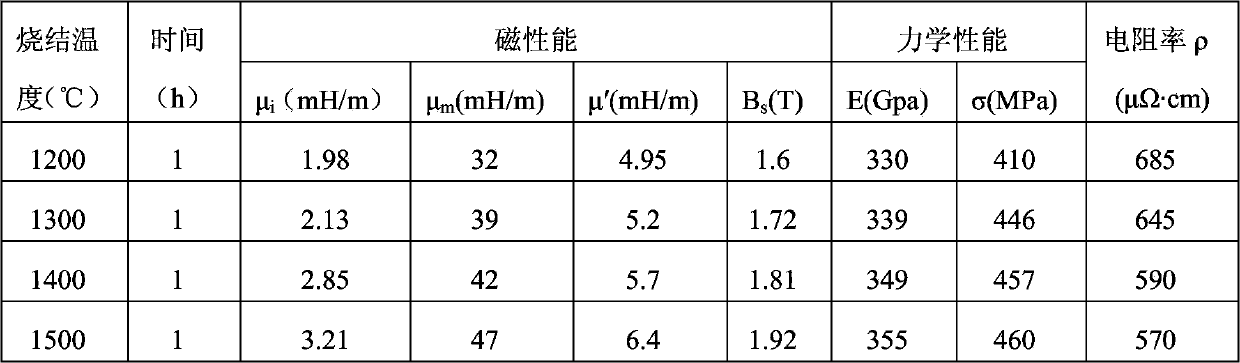

[0040] The present embodiment mainly comprises two steps, and the first step, the preparation of the soft magnetic ferrite composite powder of coated metal soft magnetic powder: (1) make composition into Ni 0.5 Zn 0.5 Fe 2.04 o 4 The soft magnetic ferrite is crushed into powder particles of 30-50μm, and the crushing method is mechanical crushing. First, it is coarsely crushed into small particles of 0.5-2mm, and then ball milling is used. (2) adding the soft magnetic ferrite powder after ball milling into the prepared roughening solution, the composition of the roughening solution is a mixed solution of potassium fluoride and hydrofluoric acid, wherein the concentration of potassium fluoride is 0.3wt%, The concentration of hydrofluoric acid was 1.6 vol%. After ultrasonic oscillation at room temperature for 15 minutes, the powder was taken out, washed with deionized water, and dried in a vacuum drying oven. (3) Put the roughened dry powder into a certain amount of sensitizat...

Embodiment 3

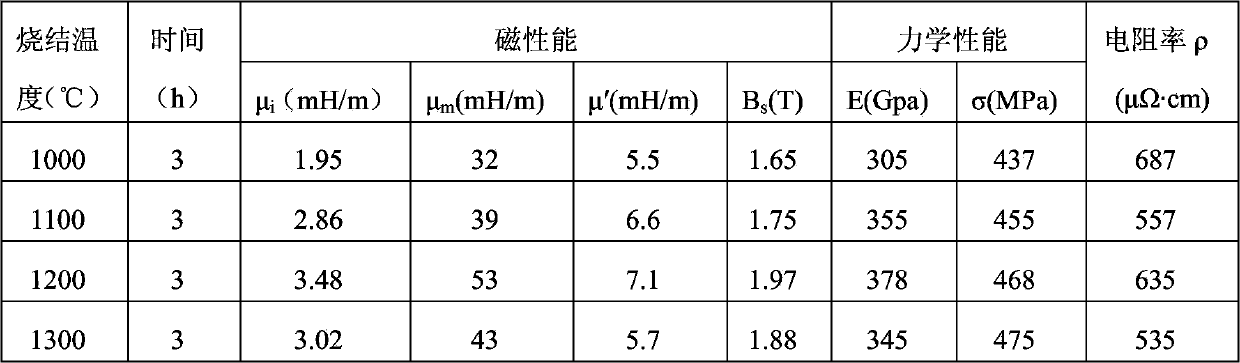

[0044] The present embodiment mainly comprises two steps, and the first step, the preparation of the soft magnetic ferrite composite powder of coated metal soft magnetic powder: (1) make composition into Ni 0.4 Zn 0.5 Cu 0.1 Fe 2.04 o 4 The soft magnetic ferrite is crushed into powder particles of 30-50μm, and the crushing method is mechanical crushing. First, it is coarsely crushed into small particles of 0.5-2mm, and then ball milling is used. (2) adding the soft magnetic ferrite powder after ball milling into the prepared roughening solution, the composition of the roughening solution is a mixed solution of potassium fluoride and hydrofluoric acid, wherein the concentration of potassium fluoride is 0.1wt%, The concentration of hydrofluoric acid is 0.9vol%. After ultrasonic vibration at room temperature for 10 minutes, the powder is taken out, washed with deionized water, and then put into a vacuum drying oven for drying. (3) Put the roughened dry powder into a certain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com