Block gadolinium-based composite amorphous magnetic cooling material and preparation thereof

A magnetic refrigeration material and bulk technology, applied in the field of metal materials, can solve the problems such as the research on the magnetocaloric effect of bulk amorphous alloys, which is in the ascendant, and achieve the effects of easy control of the microstructure of the material, simple preparation process, and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 Gd 60 co 26 Al 10 Ge 4 Preparation and Magnetocaloric Properties of (x=4) Alloy

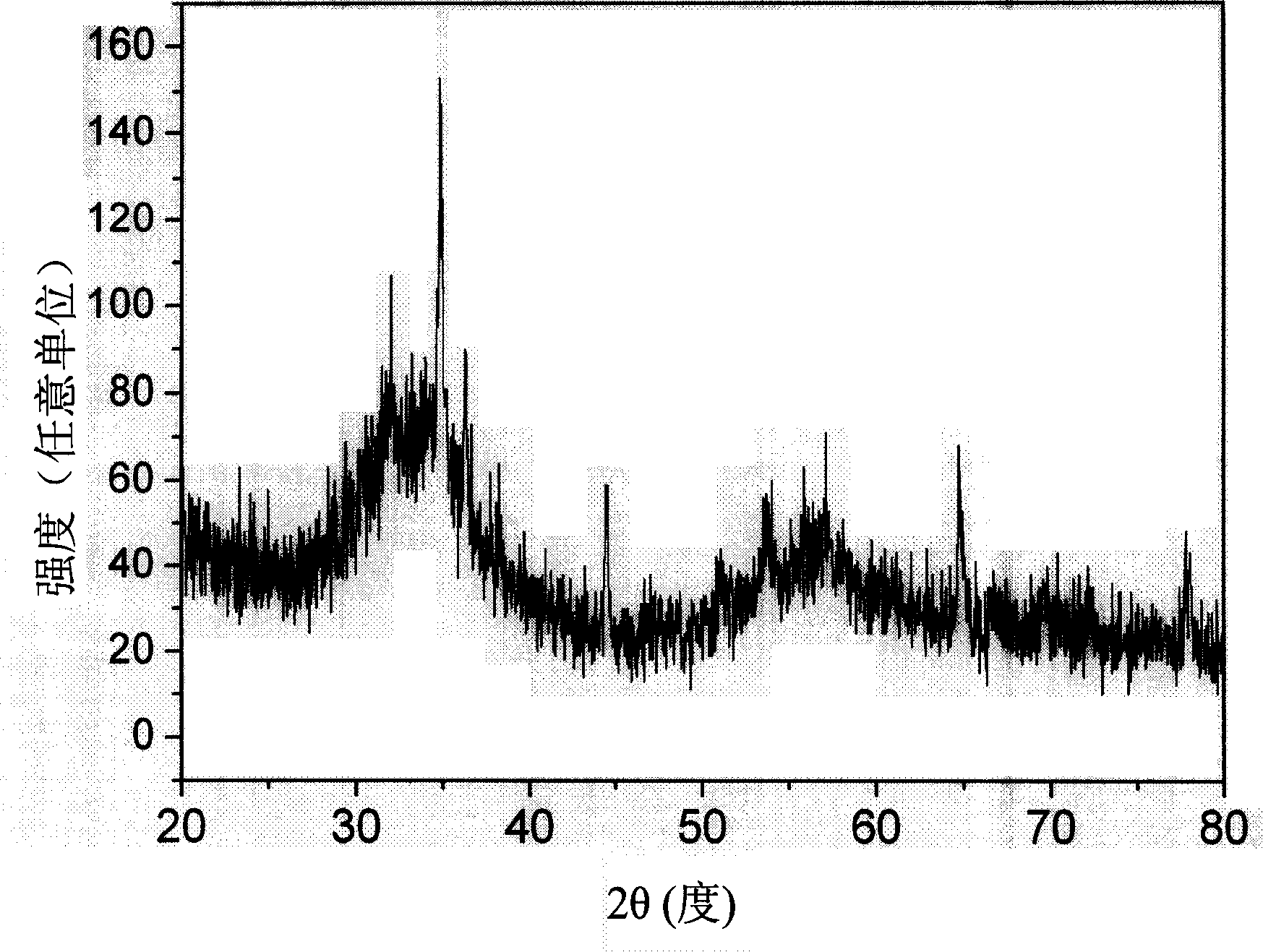

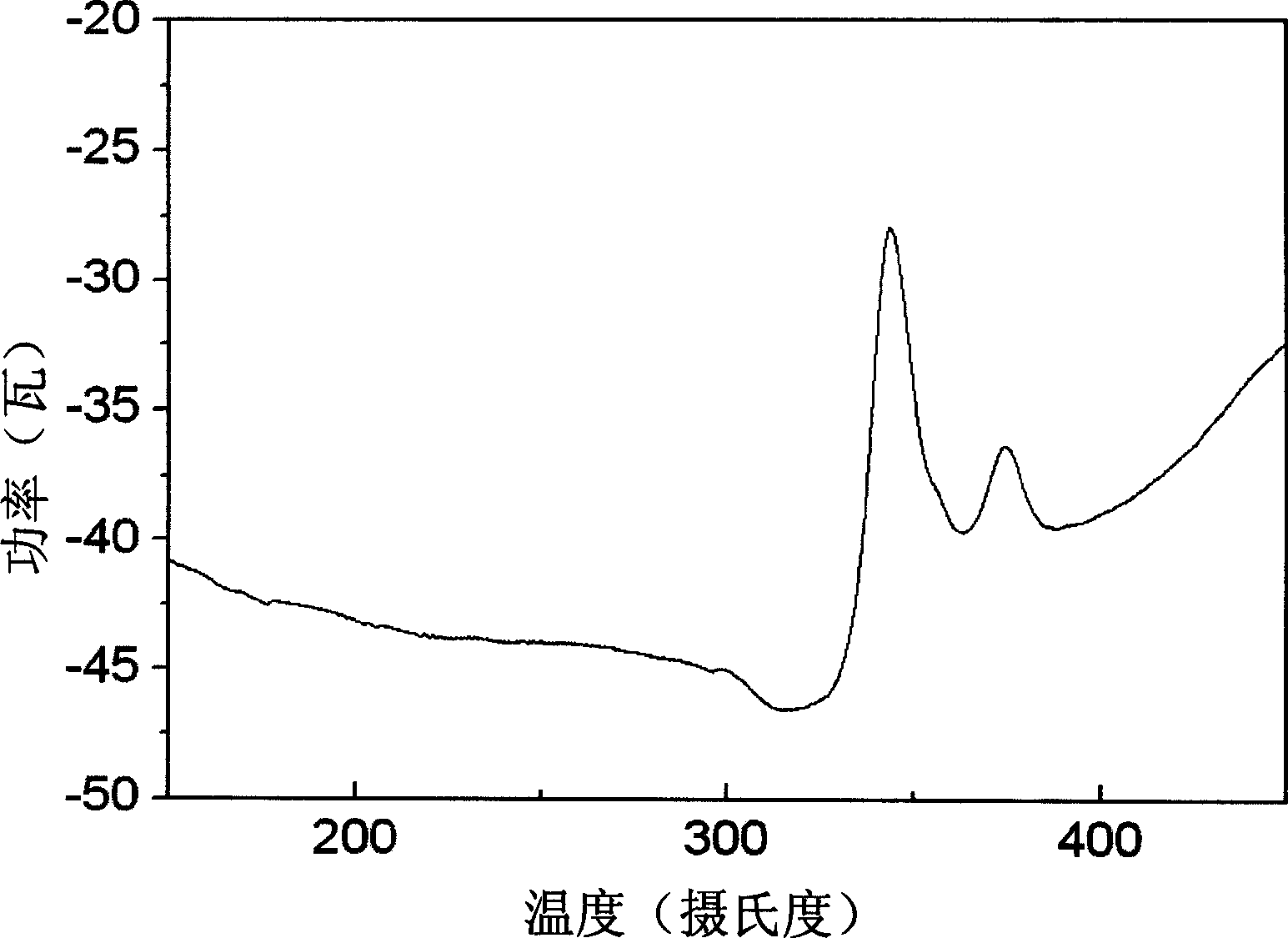

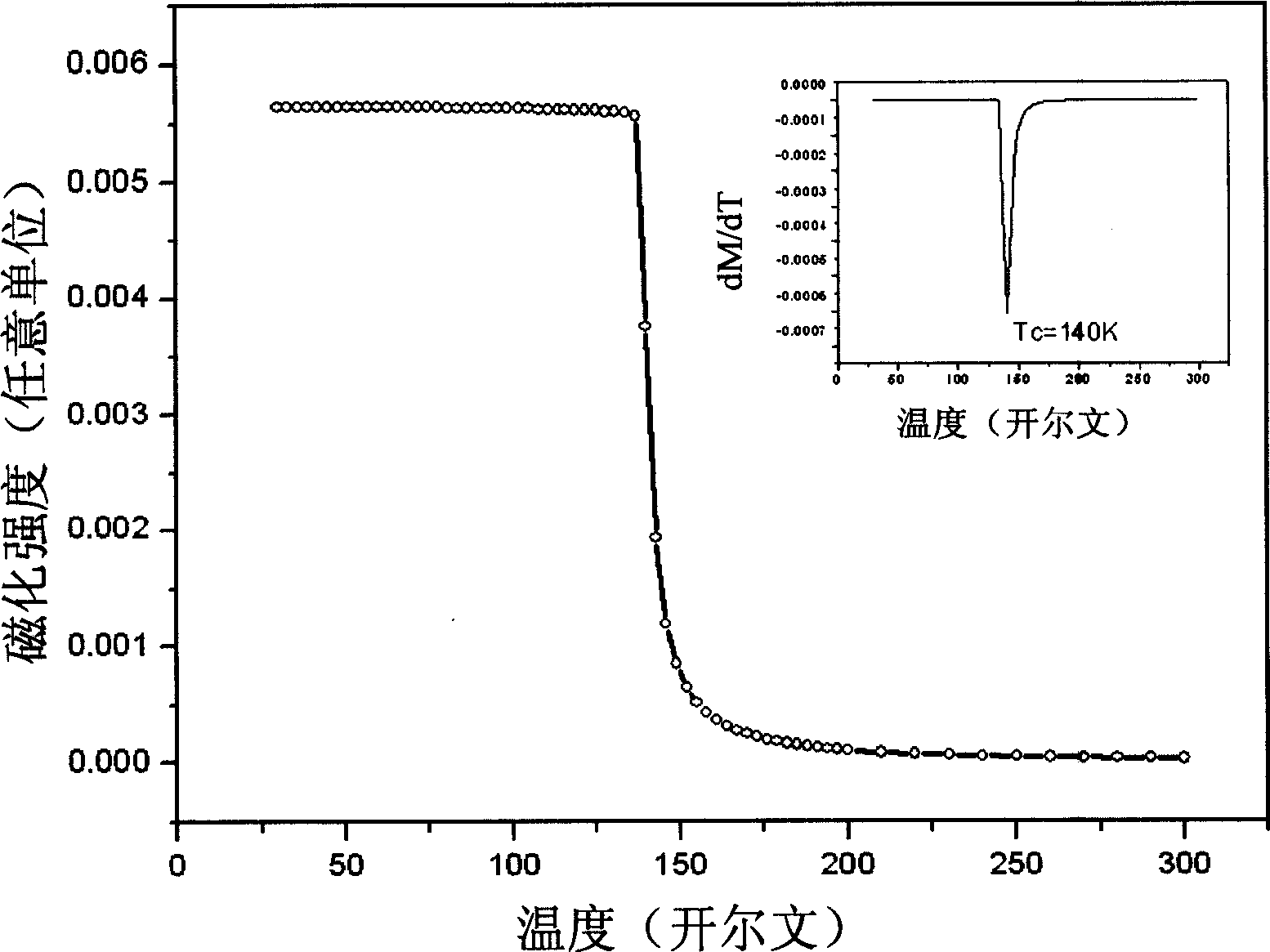

[0036] The raw materials of gadolinium, cobalt, aluminum and germanium with a purity greater than 99.9% (mass fraction) are classified as Gd 60 co 26 Al 10 Ge 4 Chemical formula weighing, put the prepared raw materials into a non-consumable vacuum electric arc furnace, and evacuate to 3×10 -5 Torr or above; after cleaning 1-2 times with high-purity argon gas cleaning method, under the protection of high-purity argon gas at 1 atmospheric pressure, it is turned over and smelted repeatedly for 4-6 times to make a master alloy; put the master alloy smelted according to the above steps into In the suction-casting copper crucible, the alloy is melted and suction-cast into a columnar sample with a diameter of 3 mm. The metallographic observation shows that the microstructure of the alloy is characterized by a large amorphous matrix and a small amount of primary crystal phase. X...

Embodiment 2

[0037] Example 2 Gd 60 co 26 Al 6 Ge 8 Preparation and Magnetocaloric Properties of (x=8) Alloy

[0038] The raw materials of gadolinium, cobalt, aluminum and germanium with a purity greater than 99.9% (mass fraction) are classified as Gd 60 co 26 Al 6 Ge 8 Chemical formula weighing, put the prepared raw materials into a non-consumable vacuum electric arc furnace, and evacuate to 3×10 -5 Torr or above; after cleaning 1-2 times with high-purity argon gas cleaning method, under the protection of high-purity argon gas at 1 atmospheric pressure, it is turned over and smelted repeatedly for 4-6 times to make a master alloy; put the master alloy smelted according to the above steps into In the suction-casting copper crucible, the alloy is melted and suction-cast into a columnar sample with a diameter of 3 mm. The metallographic observation shows that the microstructure of the alloy is characterized by a large amorphous matrix and a small amount of primary crystal phase. X-r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Initial crystallization temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com