Preparation method of porous nickel

A porous nickel and production method technology, applied in the field of porous metal materials, can solve the problems of poor sample consistency, high equipment requirements, and poor pore connectivity, and achieve the effects of adjustable pore size, low environmental pollution, and adjustable pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The present embodiment specifically implements a production method of porous nickel, which is characterized in that: pure nickel and pure zinc are melted in a crucible at a mass ratio of 3:2, and the pure nickel and pure zinc that are kept at 200°C for 1.0h are placed under the pressure of pure zinc 1. Put pure nickel on top into the crucible preheated to 700°C, and then raise the temperature to 1000°C until the pure nickel is completely melted to obtain a nickel-zinc alloy melt, adjust the melt temperature to 950°C, and Cast nickel-zinc alloy into the pure copper mold heated for 30 minutes. The effective part of the cavity of the copper mold is plate type. The size of the plate cavity is length × width × height = 200mm × 200mm × 10mm. Then carry out vacuum evaporation to the obtained nickel-zinc alloy, the nickel-zinc alloy is heated to 800 ℃, in vacuum degree 5 * 10 -2 Keep it under Pa for 30 minutes, and the obtained material is a porous nickel material.

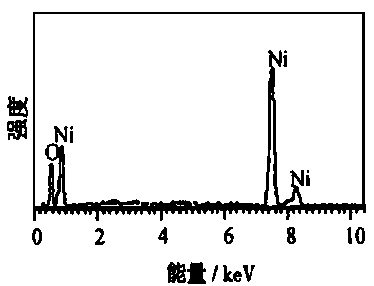

[0017] f...

Embodiment 2

[0019] This embodiment specifically implements a production method of porous nickel, which is characterized in that: pure nickel and pure zinc are melted in a crucible at a mass ratio of 5:3, and the pure nickel and pure zinc kept at 300°C for 0.5h are Put it into the crucible preheated to 750°C in the way of bottom and pure nickel on top, and then raise the temperature to 1020°C until the pure nickel is completely melted to obtain a nickel-zinc alloy melt, adjust the melt temperature to 980°C, and then The nickel-zinc alloy is poured into the pure copper mold preheated for 50 minutes. The effective part of the cavity of the copper mold is a plate type. The size of the plate cavity is length × width × height = 50mm × 50mm × 5mm. , and then carry out vacuum evaporation to the obtained nickel-zinc alloy, heat the nickel-zinc alloy to 830°C, and in a vacuum degree of 2×10 -2 Keep it under Pa for 25 minutes, and the obtained material is a porous nickel material.

[0020] The resu...

Embodiment 3

[0022] This embodiment specifically implements a production method of porous nickel, which is characterized in that: pure nickel and pure zinc are melted in a crucible at a mass ratio of 5:3, and the pure nickel and pure zinc kept at 260°C for 0.7h are Put it into the crucible preheated to 730°C in the way of bottom and pure nickel on top, and then raise the temperature to 1020°C until the pure nickel is completely melted to obtain a nickel-zinc alloy melt, adjust the melt temperature to 980°C, The nickel-zinc alloy is poured into the pure copper mold preheated for 40 minutes. The effective part of the cavity of the copper mold is plate type. , and then carry out vacuum evaporation to the obtained nickel-zinc alloy, heat the nickel-zinc alloy to 850°C, and vacuum degree 1×10 -2 Keep it under Pa for 30 minutes, and the obtained material is a porous nickel material.

[0023] The results of SEM photos and EDS energy spectrum analysis are similar to those of Example 1. After test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com