Active aluminum-rich alloy for preparing high purity hydrogen through hydrolysis and preparation method thereof

An aluminum alloy, active technology, applied in the field of alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

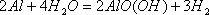

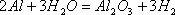

[0021] According to the mass ratio of Al 94 (Ga 3.6 In 1.8 sn 0.6 ) 6 Accurately weigh each metal, and use a 25 Kg vacuum induction furnace to smelt the alloy to a liquid state, and its vacuum degree is 10 -2 ~10 -3 Pa; then use electromagnetic stirring technology to stir the liquid alloy for about half an hour; under the protective atmosphere of argon, pour the liquid alloy into a water-cooled copper mold to solidify, and the cooling rate is controlled at 10 1 ~10 3o C / s. The diameter of the alloy ingot is less than 8 cm to ensure the fine grain size of the alloy and the GaIn 3 The distribution of Sn phase is uniform.

[0022] X-ray analysis results show that the alloy is composed of Al and GaIn 3 Sn two-phase composition, see figure 1 ; The microstructure photo shows Al as columnar grains, white granular GaIn 3 The Sn phase is uniformly distributed on the Al grains, see figure 2 ; The results of differential thermal analysis proved that GaIn 3 The melting poi...

Embodiment 2

[0024] According to the mass ratio of Al 85 (Ga 9 In 4.5 sn 1.5 ) 15 Accurately weigh each metal and melt the alloy in a 25 Kg vacuum induction furnace with a vacuum of 10 -2 ~10 -3 Pa. Electromagnetic stirring technology is used to stir the liquid alloy for about half an hour. Under an argon protective atmosphere, the liquid alloy was cast into a water-cooled copper mold for solidification, and the cooling rate was controlled at 10 1 ~10 3o C / s. The diameter of the alloy ingot is less than 8 cm.

[0025] Weigh about 5 mg of the alloy sample and put it into tap water for reaction. The reaction temperature was controlled with a water bath, and the volume of hydrogen gas produced was measured by the drainage method. Figure-5 shows alloy Al 85 (Ga9 In 4.5 sn 1.5 ) 15 The volume of hydrogen produced by reacting with water at different temperatures as a function of time. At a reaction temperature of 60 o C, the hydrogen production rate of the alloy can reach 600 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com