Method for producing hydrogen by using excess sludge

A technology for excess sludge and fermentation substrates, applied in the direction of fermentation, etc., can solve the problems of increasing the cost of the hydrogen production process, complicating the separation process, and reducing the hydrogen production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) Put 100 mL of excess sludge in a glass beaker, and use an ultrasonic processor to perform low-frequency ultrasonic treatment on the excess sludge in the glass beaker for 12 s at a sound energy density of 100 W / L to obtain hydrogen-producing seed sludge.

[0057] (2) Another 100 mL of excess sludge was placed in a glass beaker, and the excess sludge in the glass beaker was ultrasonically treated for 1 hour under the condition of an acoustic energy density of 1.56 W / mL by an ultrasonic processor to obtain a fermentation substrate.

[0058] The parameters of the hydrogen-producing seed sludge and fermentation substrate are shown in Table 1.

[0059] Table 1 is the parameters of hydrogen-producing seed sludge and fermentation substrate in Example 1 of the present invention

[0060] parameters

Hydrogen-producing mud

Fermentation substrate

SS(g / L)

23.62

20.34

VS (g / L)

12.37

9.83

TCOD(mg / L)

25843.22

23098.71

...

Embodiment 2

[0064] (1) Put 100 mL of excess sludge in a glass beaker, and use an ultrasonic processor to perform low-frequency ultrasonic treatment on the excess sludge in the glass beaker for 12 s at a sound energy density of 100 W / L to obtain hydrogen-producing seed sludge.

[0065] (2) get remaining sludge 100mL and place in the ozone reactor in addition, adopt the ozone generator to the residual sludge in the ozone reactor at 0.139g-O 3 Under the condition of ozone amount of / g-TS, carry out ozone treatment for 1h, obtain fermentation substrate.

[0066] (3) Take 5 mL of the hydrogen-producing seed slurry obtained in the above step (1), inoculate it into an anaerobic bottle filled with 95 mL of the fermentation substrate obtained in the above step (2), blow off nitrogen for 10 minutes, and then place the anaerobic bottle in Oscillate in a constant temperature water bath shaker at 35±1°C, and control the oscillation speed to 135r / min to obtain hydrogen gas.

[0067] The hydrogen produ...

Embodiment 3

[0069] (1) Put 100 mL of excess sludge in a glass beaker, and use an ultrasonic processor to perform low-frequency ultrasonic treatment on the excess sludge in the glass beaker for 12 s at a sound energy density of 100 W / L to obtain hydrogen-producing seed sludge.

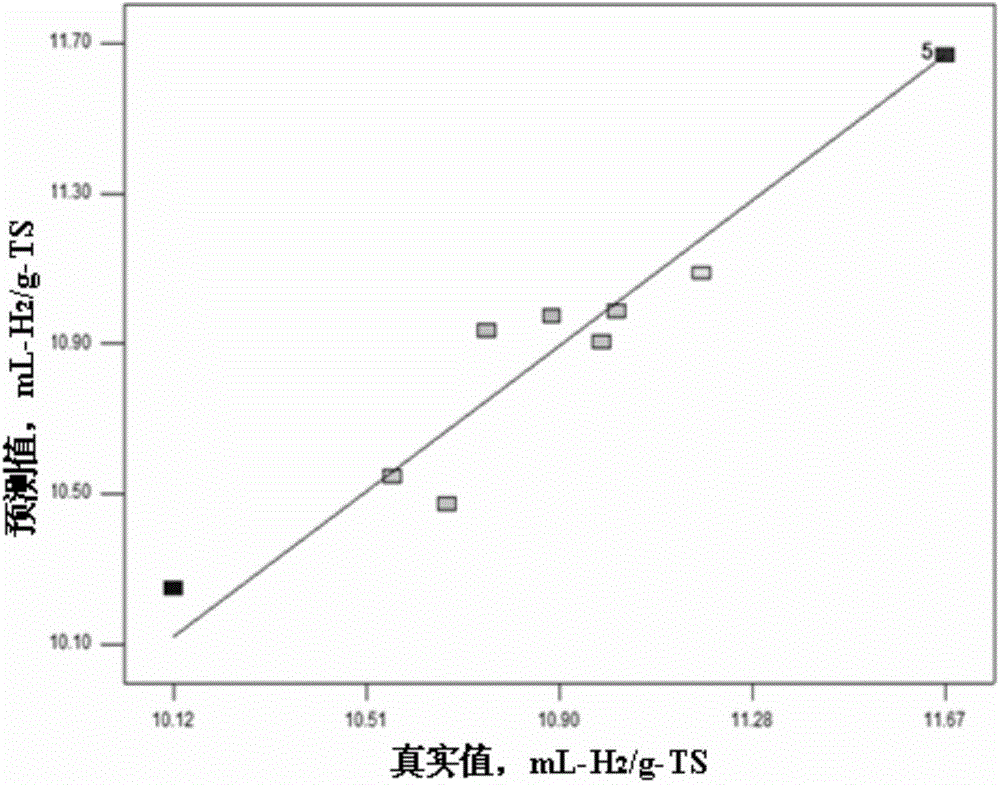

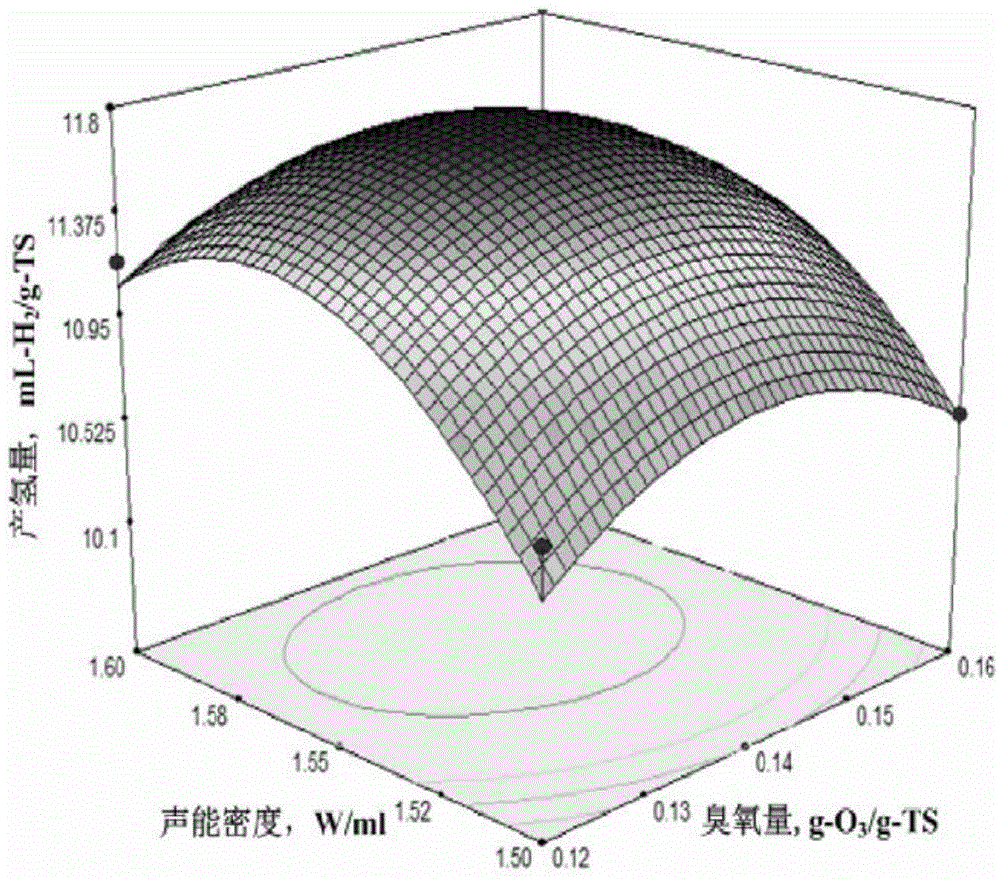

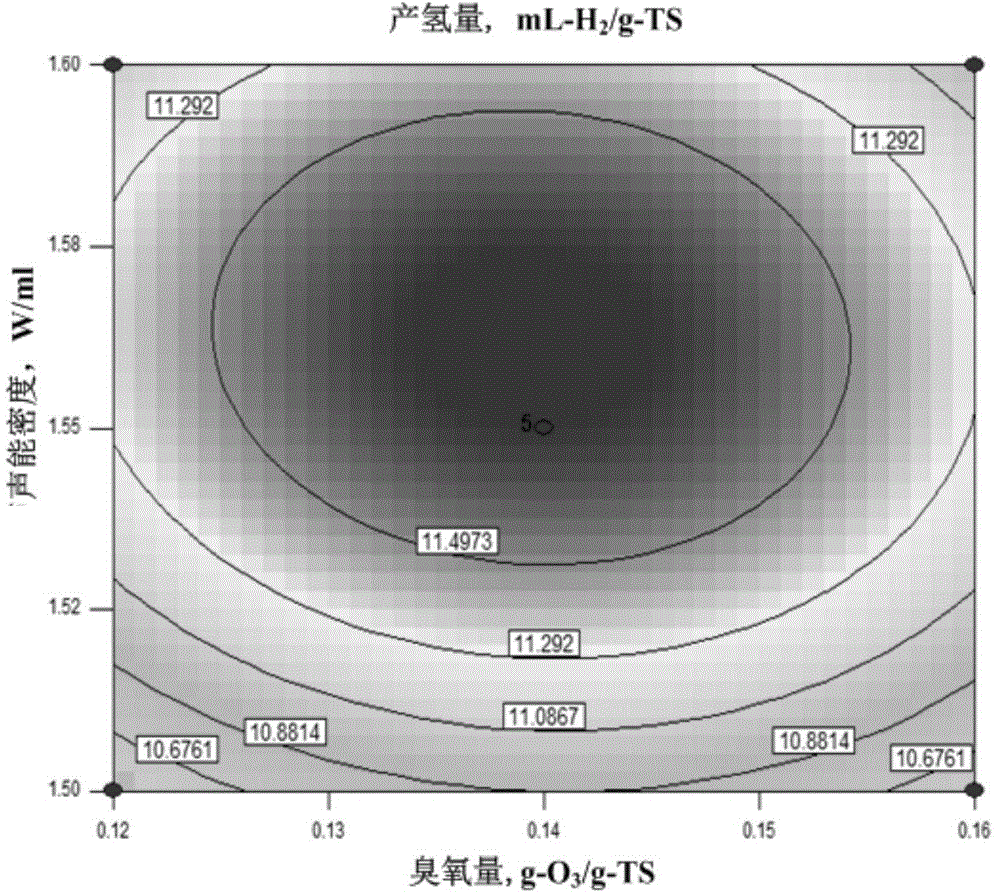

[0070] (2) Take another 100mL of excess sludge and place it in an ultrasonic-ozone coupling reaction device. 3 Under the condition of ozone amount of / g-TS, ozone treatment was carried out, and at the same time, the excess sludge in the process of ozone treatment was subjected to ultrasonic treatment under the condition of sound energy density of 1.55W / mL, and the reaction time was 1h to obtain the fermentation substrate.

[0071] (3) Take 5 mL of the hydrogen-producing seed slurry obtained in the above step (1), inoculate it into an anaerobic bottle filled with 95 mL of the fermentation substrate obtained in the above step (2), blow off nitrogen for 10 minutes, and then place the anaerobic bottle in Oscillate in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com