Mg-Mg2Si composite hydrolytic hydrogen production material, preparation method thereof, and method using material to realize hydrolytic hydrogen production

A composite material and composite hydrolysis technology, which is applied in the field of Mg-Mg2Si composite hydrolysis hydrogen production materials and its preparation, can solve the problems of decreased hydrolysis reaction kinetics, low hardness of pure magnesium metal, and difficult hydrolysis performance, so as to improve hydrolysis performance, The effect of high hydrogen production rate, simple production process and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In a glove box with 0.1MPa argon atmosphere, the Mg-14wt.%Mg 2 The Si alloy block is initially crushed. After crushing, it is put into a ball mill tank and placed in a high-energy planetary ball mill (QM-3SP4). The ball-to-material ratio is 30:1, the ball mill speed is 350 rpm, and it runs for 15 minutes. Stop for 5 minutes alternately, ball mill in argon atmosphere for 20h; after ball milling, take powder in argon atmosphere glove box, and after passing 200 mesh standard inspection sieve, collect sample powder with fine and uniform particles (Mg- 14wt.%Mg 2 Si composite material).

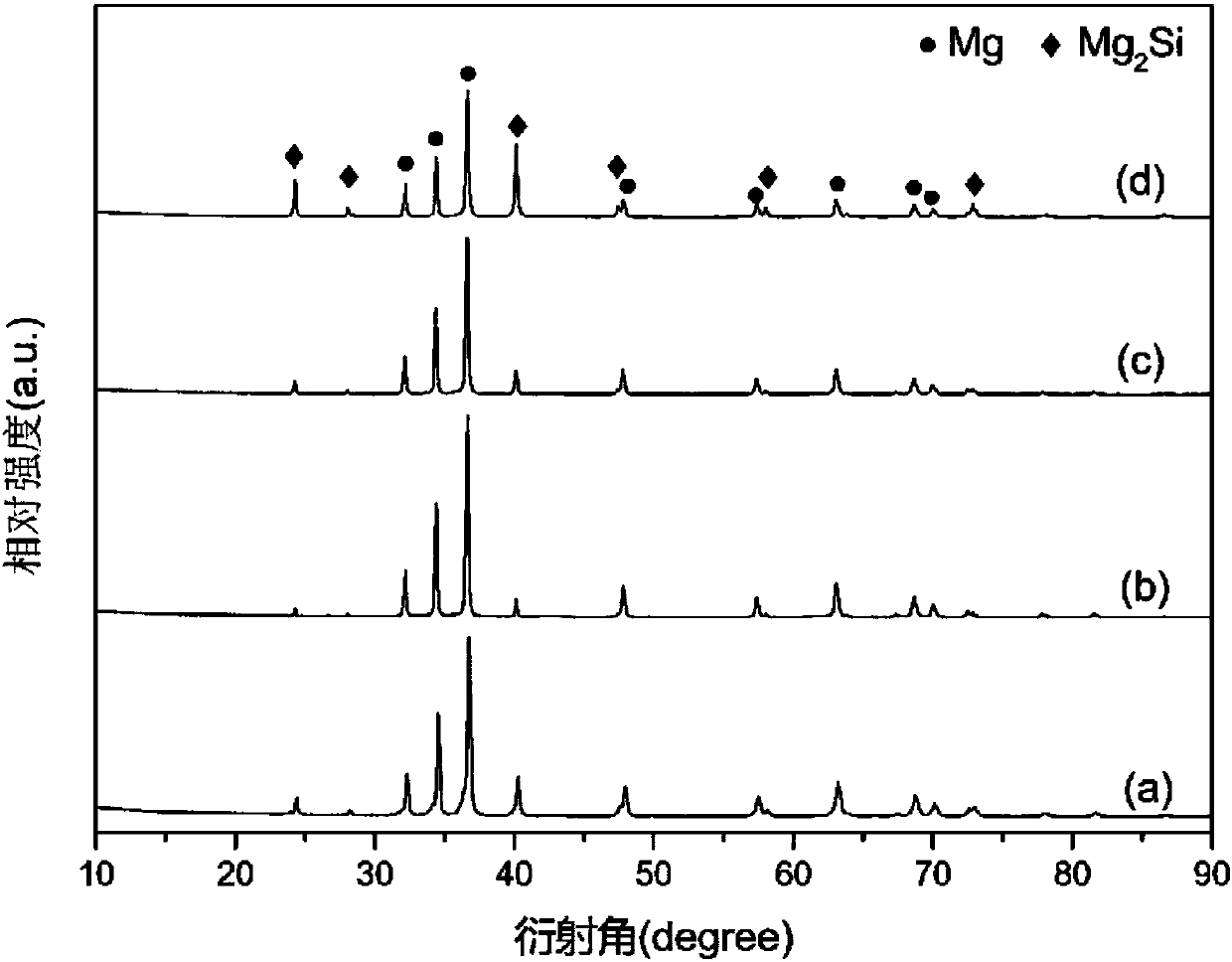

[0047] The XRD pattern of the sample powder obtained by ball milling is as follows figure 1 As shown by the curve (a) in figure 1 Middle curve (a) shows that except for Mg and Mg in the curve 2 Si diffraction peak, no obvious impurity peak and MgO peak are seen, which proves that the sample powder has few impurities and is not oxidized.

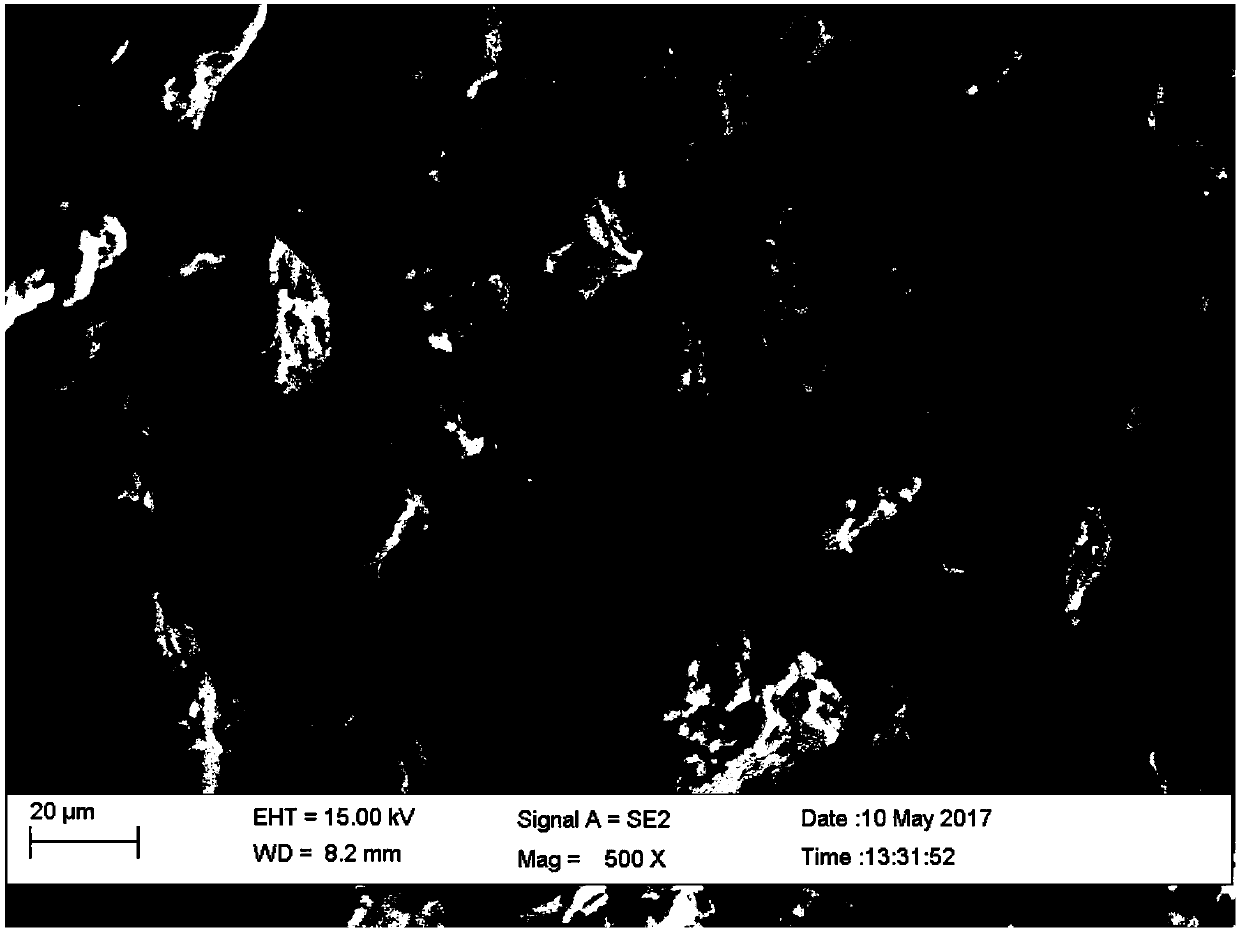

[0048] The SEM secondary electron scanning image of the s...

Embodiment 2

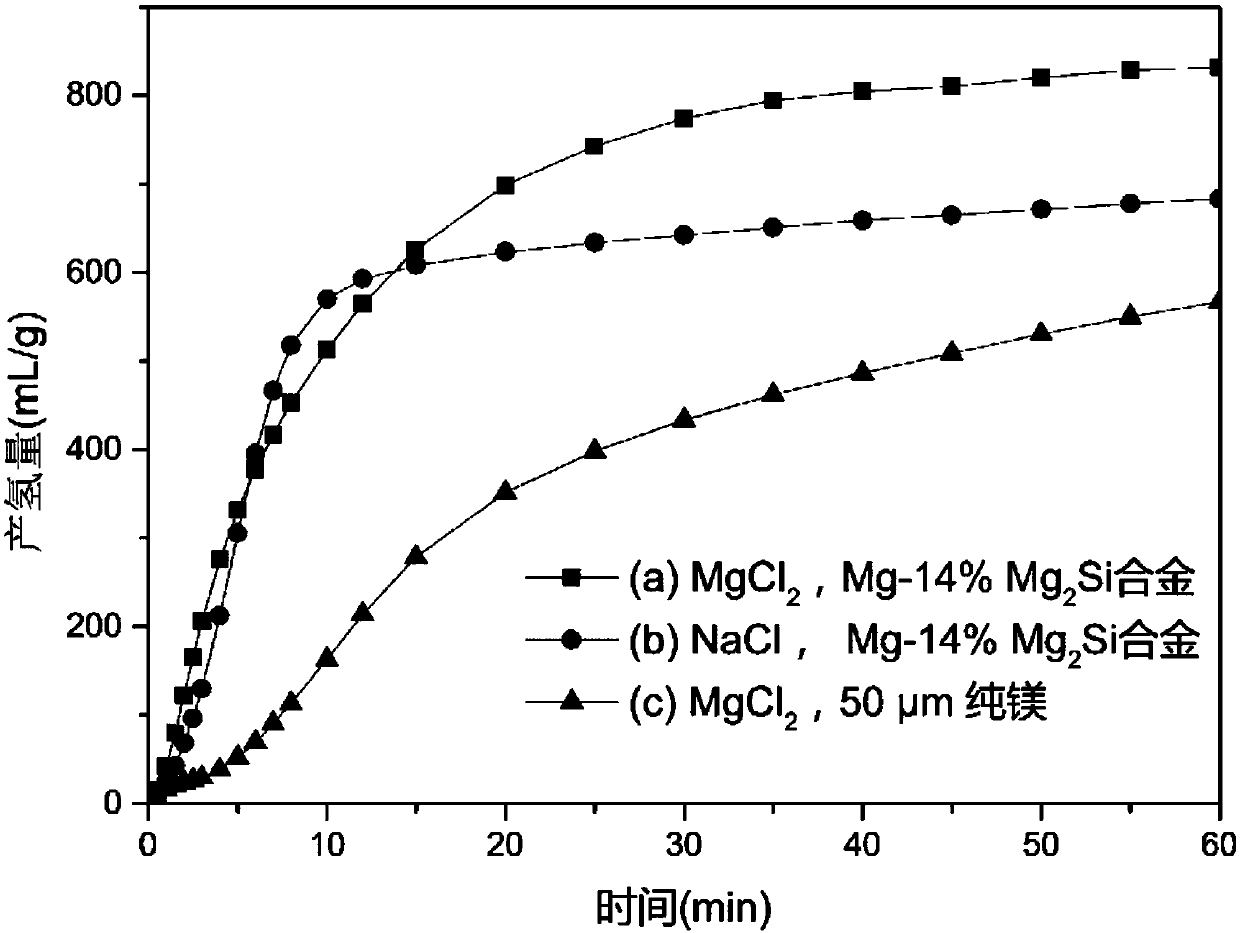

[0055] Take 0.1g of the sample powder prepared in Example 1 (Mg-14wt.%Mg 2 Si composite material) and 30mL MgCl 2 The solution (concentration is 0.5mol / L) is hydrolyzed at room temperature, 40℃, 55℃ and 70℃;

[0056] The hydrolysis reaction is carried out at room temperature, the hydrolysis reaction is mild, 648mL / g of hydrogen is released within 10 minutes, and 766mL / g of hydrogen is released within 30 minutes;

[0057] The hydrolysis reaction is carried out at a temperature of 40°C, and the hydrolysis reaction is mild, with 578mL / g of hydrogen released within 10 minutes, and 827mL / g of hydrogen released within 30 minutes;

[0058] The hydrolysis reaction is carried out at a temperature of 55°C, the hydrolysis reaction is mild, 688mL / g of hydrogen is released within 10 minutes, and 875mL / g of hydrogen is released within 30 minutes;

[0059] The hydrolysis reaction is carried out at a temperature of 70°C, and the hydrolysis reaction is mild, with 877mL / g of hydrogen released within 10 ...

Embodiment 3

[0062] In a glove box with 0.1MPa argon atmosphere, combine Mg powder with Mg 2 After the Si powder is mixed according to the mass ratio of 19:1, it is put into the ball milling tank and placed in the high-energy planetary ball mill (QM-3SP4) with the ball-to-material ratio of 20:1, the ball milling speed is 400 rpm, and running for 15 Minutes and stops for 5 minutes alternately, ball milling in argon atmosphere for 2h; after ball milling, take powder in an argon atmosphere glove box, and after passing through a 200-mesh standard inspection sieve, collect the sample powder with fine and uniform particles (Mg -5wt.%Mg 2 Si composite material).

[0063] The XRD pattern of the sample powder obtained by ball milling is as follows figure 1 As shown in the curve (b) in figure 1 Middle curve (b) shows that except for Mg and Mg in the curve 2 Si diffraction peak, no obvious impurity peak and MgO peak are seen, which proves that the sample powder has few impurities and is not oxidized.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com