Process for the separation of hydrogenogen of pentose and hexose at high temperature

A technology for the separation of pentose and hexose sugars, which is applied in the field of separation of high-temperature hydrogen-producing bacteria, can solve the problems of low utilization rate of lignocellulosic raw materials and low hydrogen production rate, expand the scope of substrate utilization, increase hydrogen production rate, and improve The effect of substrate availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

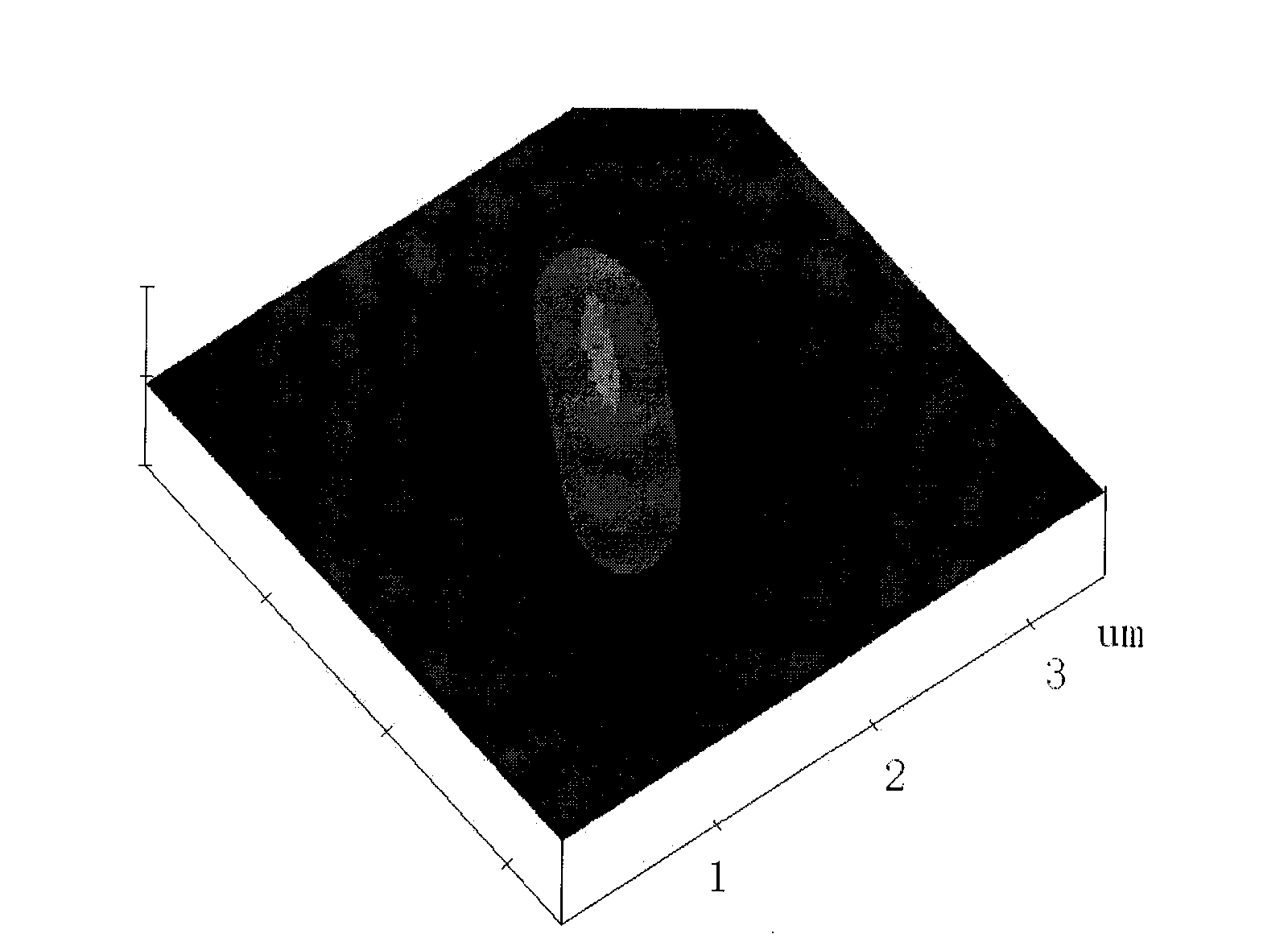

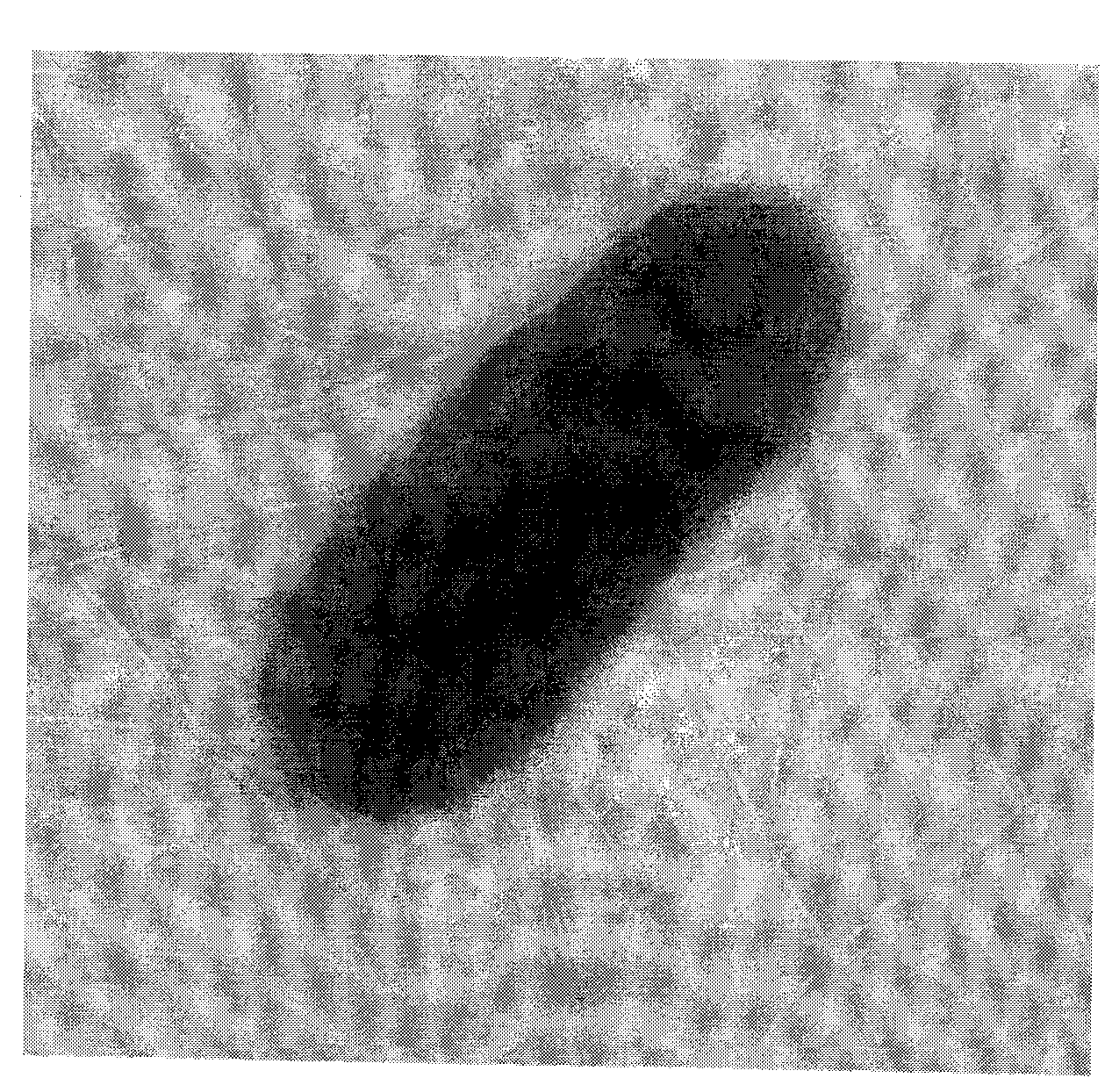

[0008] Specific embodiment one: the separation method of pentose hexose high-temperature hydrogen-producing bacteria in this embodiment is realized according to the following steps: Put it into a 250mL sterilized serum bottle filled with several glass balls, then add 80-120mL sterilized water, seal it after passing through nitrogen gas, and then shake it at a vibration speed of 100-200r / min for 4-6 hours to obtain bacterial suspension A; 2. Transfer 4-6mL of bacterial suspension A into a 250mL sterilized serum bottle filled with 100mL mixed sugar solid medium, and then incubate at a constant temperature of 60±2°C for 3-5 days to obtain the enriched bacterial suspension. 3. Take 1mL of the enriched bacterial suspension and then dilute it with sterile anaerobic water, and then take the diluted 10 4 times, 10 5 times and 10 6 Roll the tube with 1mL of the 1-fold dilution, and then culture it at a constant temperature at 60±2°C until colonies appear in the tube; Cultivate at a ...

specific Embodiment approach 2

[0009] Embodiment 2: This embodiment differs from Embodiment 1 in that the sample collected in step 1 is solid hot spring bottom mud, solid straw pile waste or solid high-temperature organic wastewater anaerobic reactor activated sludge. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0010] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the purity of nitrogen in step 1 is 99.99%. Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com