Plasticity enhancement massive metal glass material and preparation method thereof

A metallic glass and plasticity technology, applied in the fields of condensed matter physics and material science, can solve problems such as difficulty in controlling the percentage of the second phase, inability to repeatedly prepare composite materials, increase the difficulty of composite material preparation, etc., and achieve the effect of improving plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

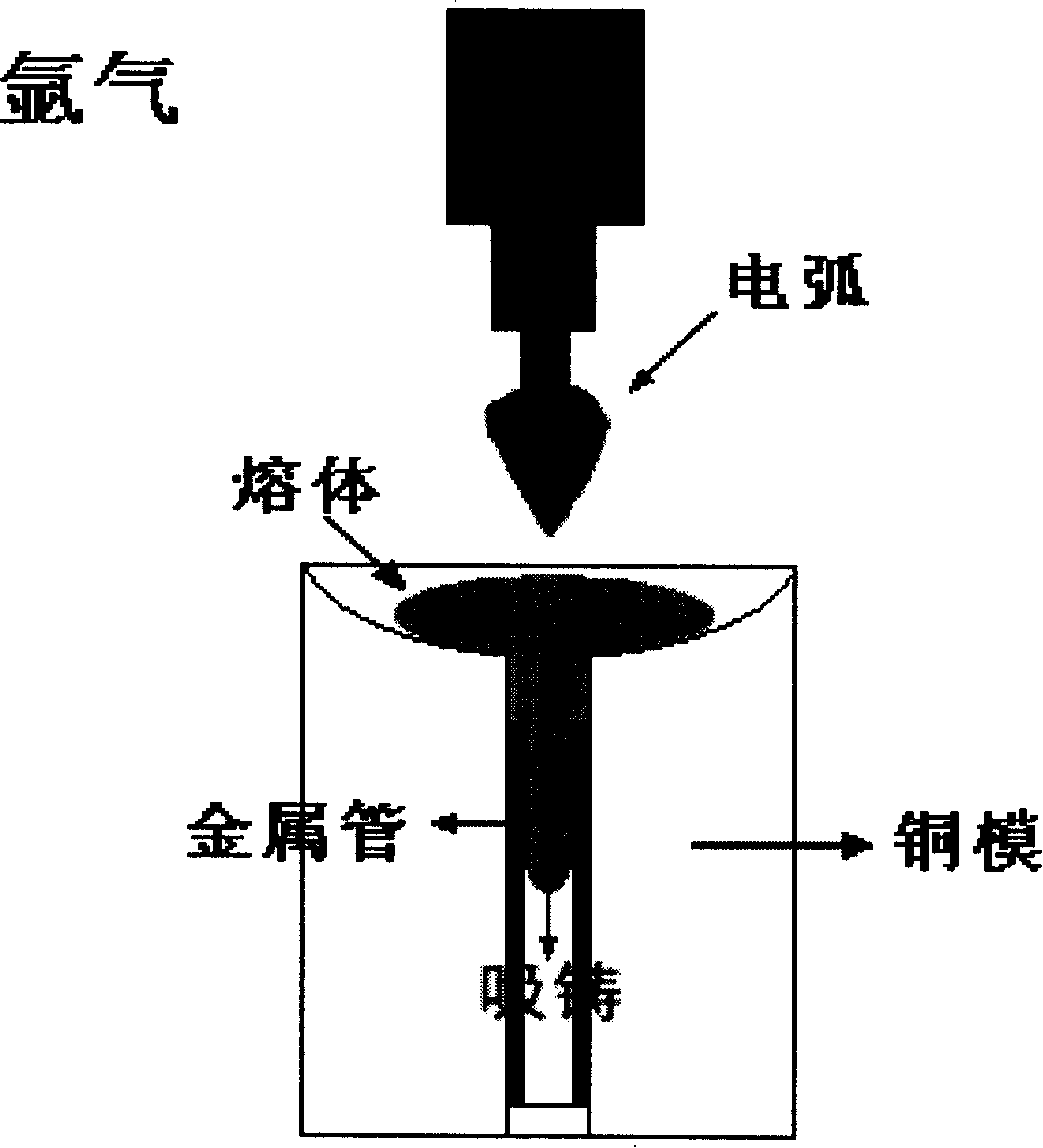

[0033] First of all, Zr, Ti, Cu, Ni, Be with a purity of 99.9% are 41.2 Ti 13.8 Cu 12.5 Ni 10 Be 22.5 The raw material is smelted into a uniform master alloy ingot in an argon atmosphere with titanium adsorption. Secondly, prepare a copper tube with a length of 4 cm, an outer diameter of 4 mm, and an inner diameter of 3 mm. The inner and outer surfaces of the copper pipe are polished with sandpaper to remove surface oxides, and the inner surface is corroded with hydrofluoric acid for 5 minutes to improve the inner surface. For roughness, clamp the processed copper pipe in a water-cooled copper mold with a diameter of 4 mm. Finally follow figure 1 In a schematic way, in an argon atmosphere, the master alloy ingot is smelted with an electric arc, and the melt is sucked and cast into the mold to prepare a copper tube-wrapped Vit1 amorphous alloy.

[0034] Figure 2~4 They are the actual photos, SEM photos and XRD images of the sample. The alloy and the copper tube are very tightly c...

Embodiment 2

[0036] First of all, Zr, Ti, Cu, Ni, Be with a purity of 99.9% are 41.2 Ti 13.8 Cu 12.5 Ni 10 Be 22.5 The raw material is smelted into a uniform master alloy ingot in an argon atmosphere with titanium adsorption. Secondly, prepare a steel pipe with a length of 4 cm, an outer diameter of 6 mm, and an inner diameter of 4 mm. The inner and outer surfaces are sanded to remove surface oxides, and the inner surface is corroded with hydrofluoric acid for 10 minutes to improve the roughness of the inner surface. The steel pipe is clamped in a 6mm water-cooled copper mold. Finally follow figure 1 In a schematic way, in an argon atmosphere, the master alloy ingot is smelted with an electric arc, and the melt is sucked and cast into the mold to prepare a Vit1 amorphous alloy wrapped in a steel pipe. See the physical map of the sample Figure 7 . The detailed test of the sample is as in Example 1, and will not be repeated.

[0037] Table 1: Uniaxial compression results of copper tube wrapped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com