Method for preparing bulk amorphous alloy under non-vacuum condition and equipment

A non-vacuum, amorphous technology, applied in the field of bulk amorphous alloy preparation, can solve problems such as unfavorable large-scale production and popularization and application of bulk amorphous alloys, cost and operation constraints, and achieves easy control of process conditions and convenient operation. , The effect of preparation equipment is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Smelting example

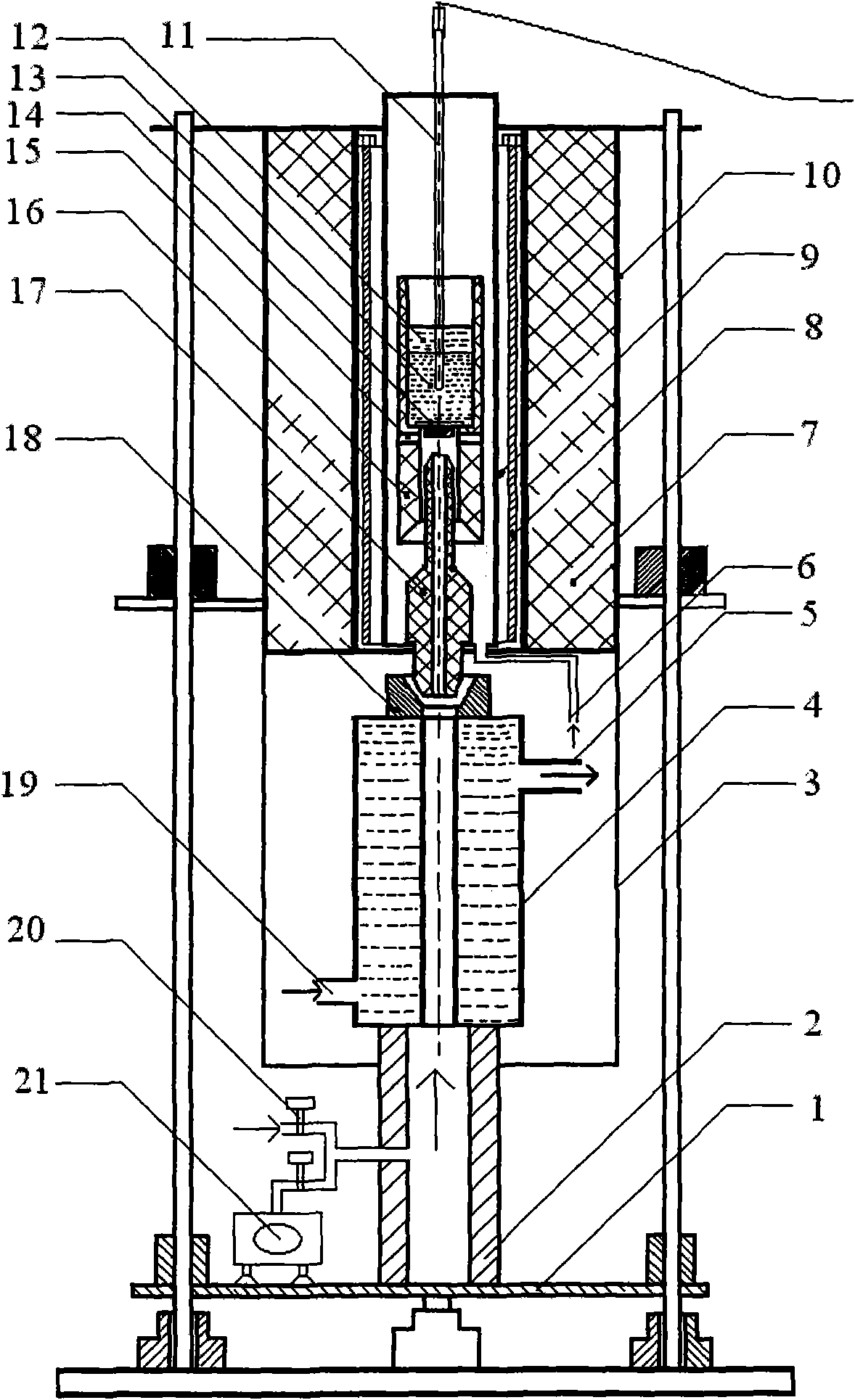

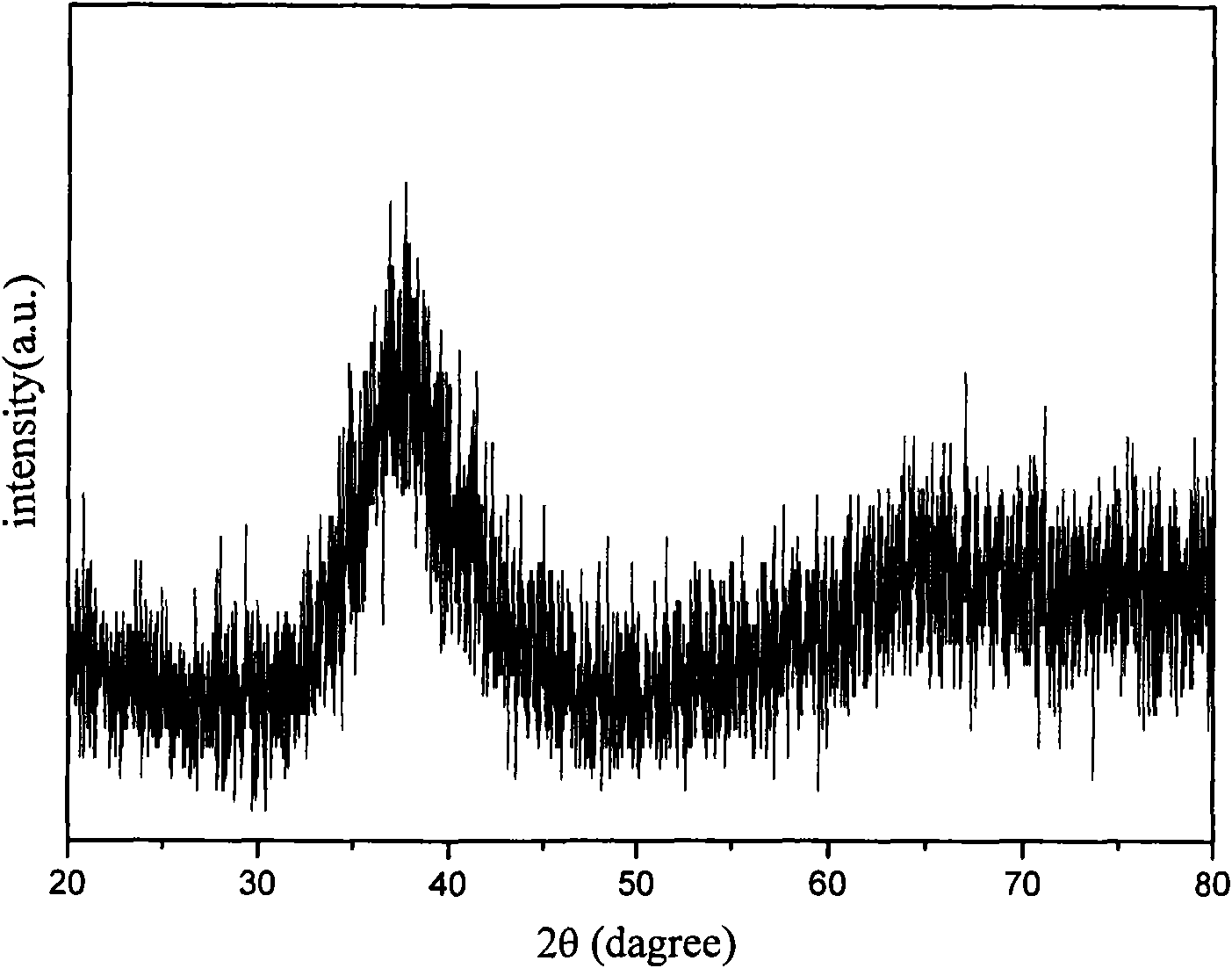

[0020] Four high-purity pure metals are selected, namely Zr (99.99wt%), Ni (99.99wt%), Al (99.99wt%), Cu (99.99wt%). According to the ratio of Zr55, Ni5, Al10 and Cu30 in atomic percentage, the master alloy is prepared by arc melting under the protection of argon with a purity of 99.8%. In order to ensure the uniformity of each component in the master alloy, the master alloy is remelted three times to make button material. Grind and polish the surface of the button material to remove the scale on the surface, and then clean the surface with alcohol. Use attached figure 1 The device shown, according to the working principle as mentioned above, can produce an amorphous rod with a diameter of 5 mm. Utilize X-ray diffractometer inspection, this amorphous rod diffraction spectrum is as attached figure 2As shown, there is only one diffuse amorphous diffusion peak on the curve, and there is no obvious diffraction peak corresponding to the crystalline ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com