Method for preparing ultra-hydrophilic zinc oxide/titanium oxide film by using layer-by-layer self-assembling method

A technology of titanium oxide film and layer-by-layer self-assembly, which is applied in the field of super-hydrophilic film preparation, can solve the problems of heavy metal pollution, high energy consumption, and high cost, and achieve the effects of stable properties, simple production equipment, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

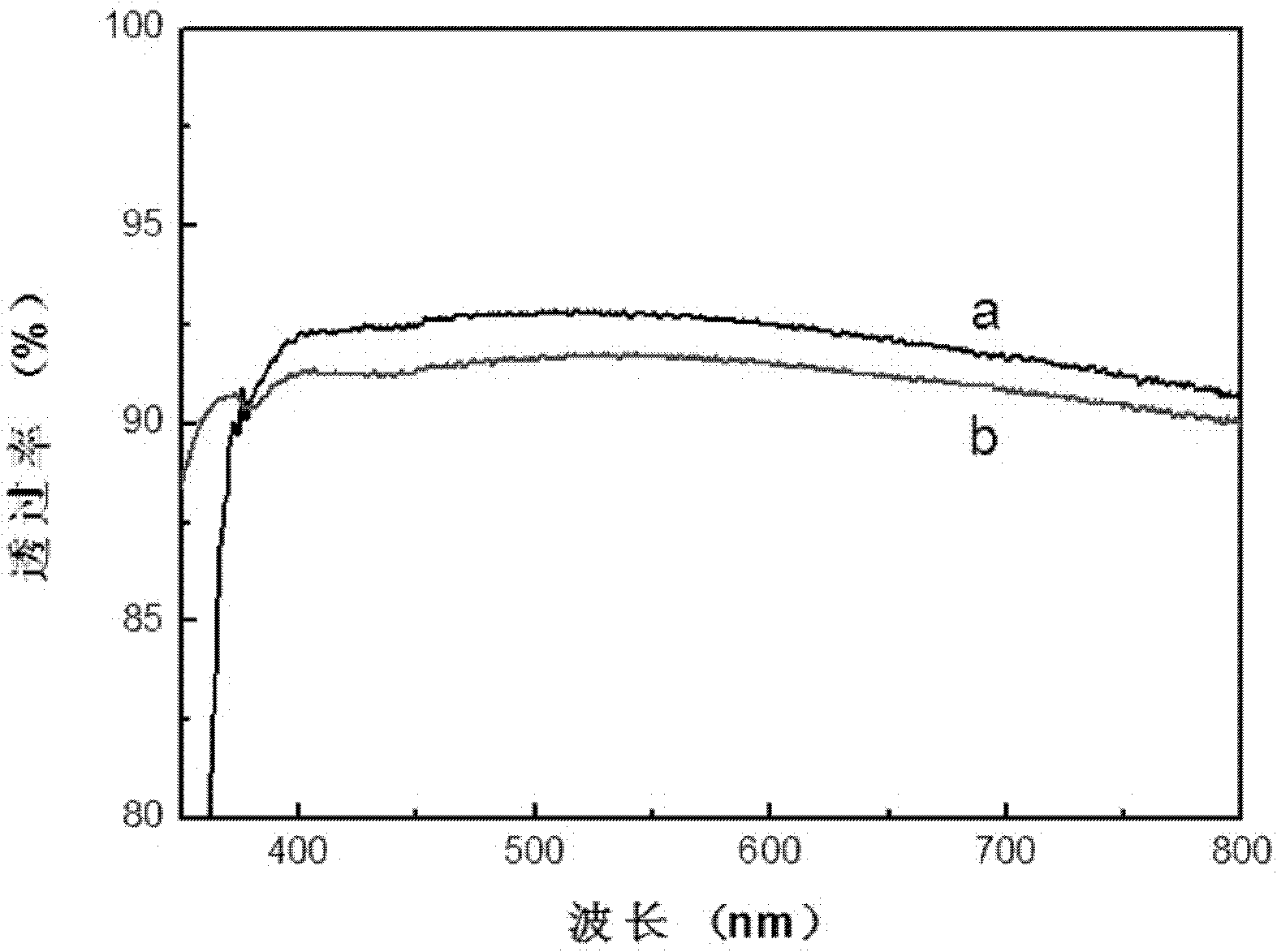

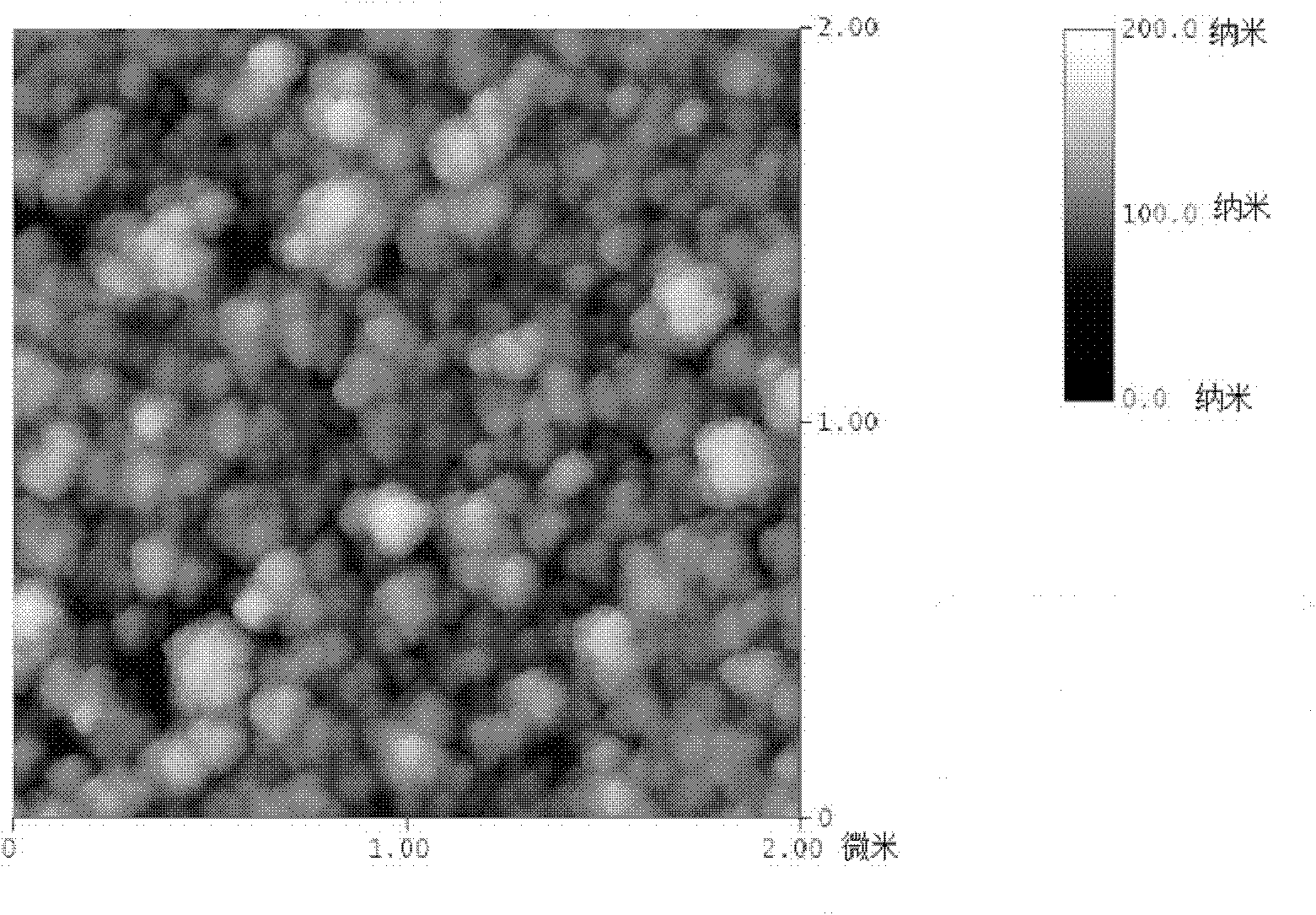

[0038] After pickling, alkali washing and drying the glass substrate, the average transmittance of the white glass substrate in the visible light region is about 89%. figure 1 b. The self-made zinc oxide is diluted, wherein the mass percentage of zinc oxide is 0.01wt%, and the pH value is 7.5. The titanium dioxide colloid is self-made, wherein the titanium dioxide is an anatase phase, the grain size is about 7nm, the mass percentage of the titanium dioxide is 0.01wt%, and the pH value is 7.9. At room temperature and normal pressure, first immerse a white glass sheet with a length of 76.2mm, a width of 25.4mm, and a thickness of 1mm in the colloid containing zinc oxide for 10 minutes, then rinse it with deionized water for 5 minutes, and then immerse it in the colloid of titanium dioxide 15 minutes, this is one layer, and then repeated 7 times in order to make it 8 layers with a thickness of 160nm. After drying, the transmittance was measured. The film layer is colorless an...

Embodiment 2

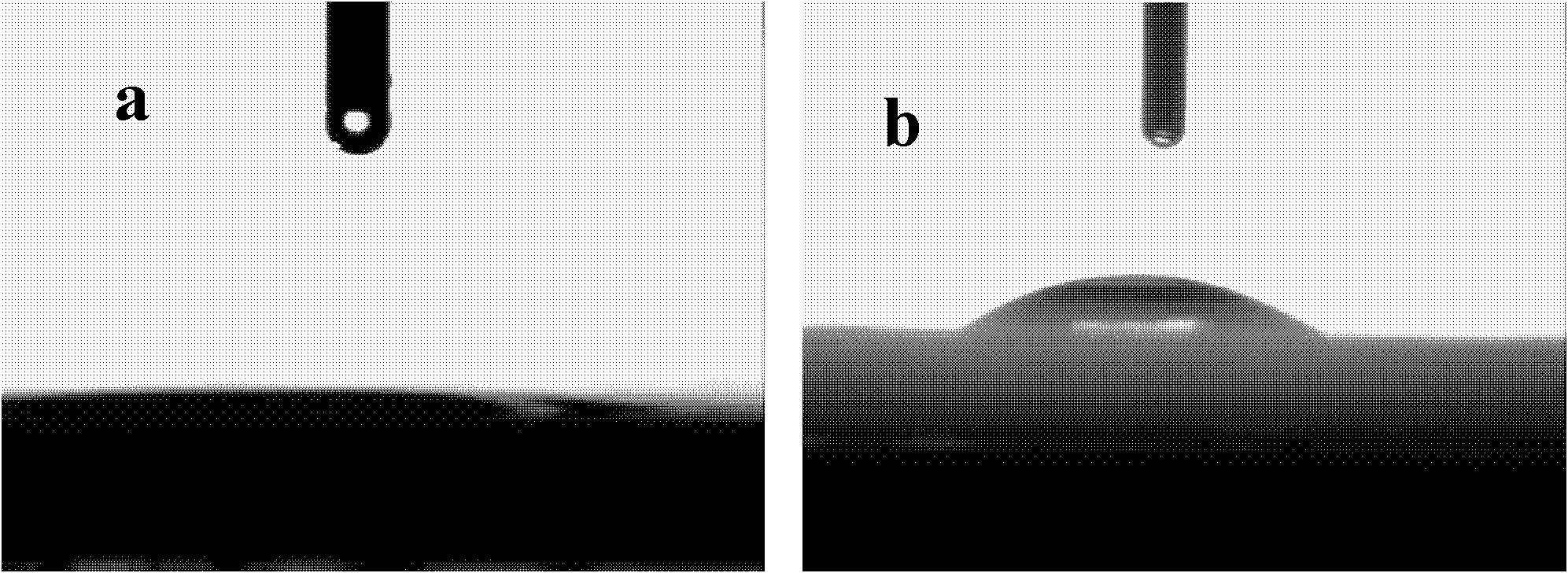

[0041] At room temperature and pressure, first immerse a glass sheet with a length of 76.2mm, a width of 25.4mm, and a thickness of 1mm in the colloid containing zinc oxide for 20 minutes, then rinse it with deionized water for 5 minutes, dry it, and then immerse it in the colloid of titanium dioxide. Put in the colloid for 10 minutes, then rinse with deionized water for 5 minutes, dry this to form a layer, and repeat 11 times in order to make it reach 12 layers with a thickness of 260nm. The titanium dioxide colloid is self-made, wherein the titanium dioxide is an anatase phase, the grain size is about 7nm, the mass percentage of the titanium dioxide is 0.952wt%, and the pH value is 9.1. The self-made zinc oxide colloid is prepared by ultrasonic dispersion with distilled water, wherein the mass percentage of zinc oxide is 0.948wt%, and the pH value is 8.9. The contact angle of the film was measured after drying. Within 5 seconds, water is completely spread on the surface of ...

Embodiment 3

[0044] At normal temperature, the colloid containing zinc oxide is prepared, and the self-made zinc oxide colloid is diluted to the mass percentage: 0.037wt%, and the pH value is 9.2. Titanium dioxide-containing colloid is prepared by diluting the self-made titanium dioxide sol with deionized water, wherein the mass percentage of titanium dioxide is 0.072wt%, and the pH value is 8.5. After the conductive substrate FTO is ultrasonically cleaned with acetone and ethanol, it is dried, and at room temperature and pressure, a white glass sheet with a length of 76.2 mm, a width of 25.4 mm, and a thickness of 1 mm is first immersed in a colloid containing zinc oxide for 15 minutes. Then rinse with deionized water for 3 minutes, and then soak it in titanium dioxide colloid for 3 minutes, which is one layer, and repeat 11 times in order to make it reach 12 layers, which is calculated as FTO / (zinc oxide / titanium dioxide) 12 , with a thickness of 260nm.

[0045] In the preparation of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com