Soft-magnetic high-entropy block amorphous alloy FeCoNiMB and preparation method thereof

An amorphous alloy and soft magnetic technology, applied in the field of FeCoNiMB high-entropy bulk amorphous alloy and its preparation, to achieve the effect of expanding the application field, high strength, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

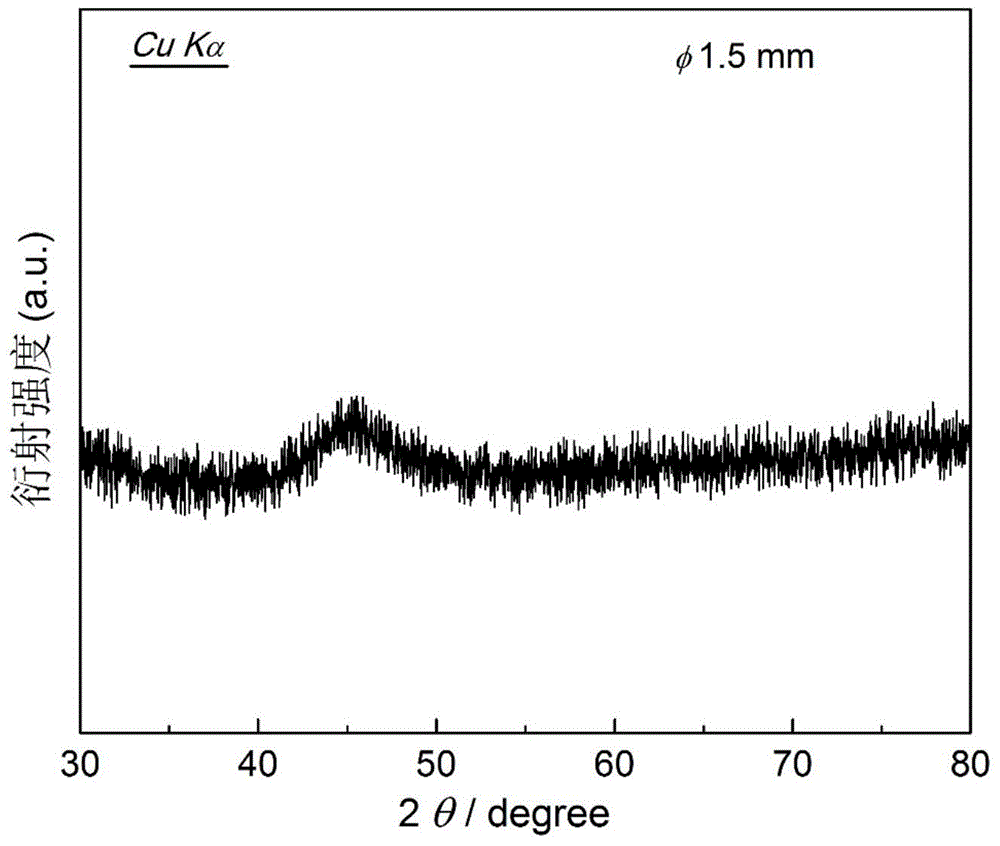

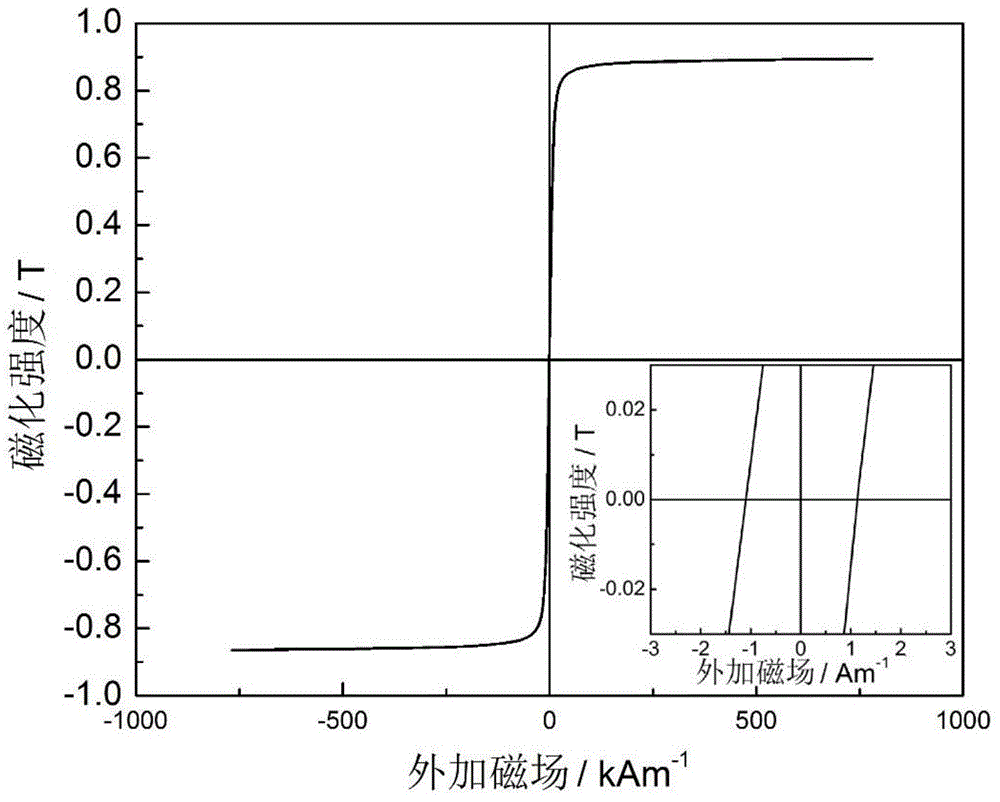

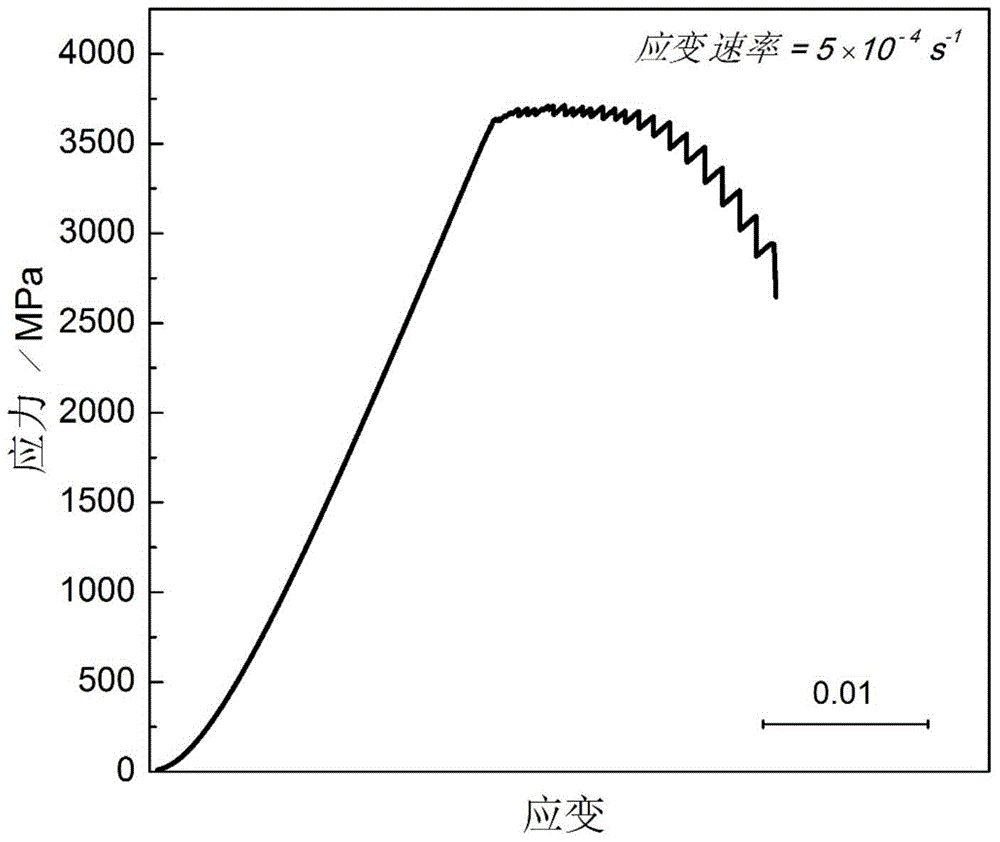

[0024] Example 1: Fe 25 co 25 Ni 25 Si 7.5 B 17.5

[0025] Step 1. Ingredients

[0026] Fe, Co, Ni, B and Si raw materials with a purity greater than 99.5wt% are used for weighing and proportioning according to the nominal composition;

[0027] Step 2: Master alloy ingot smelting

[0028] Mix the weighed metal raw materials into a water-cooled copper crucible of a non-consumable arc melting furnace, and repeatedly smelt them 4 times under an Ar gas atmosphere to obtain an alloy ingot with a uniform composition;

[0029] Step 3: Preparation of amorphous rod

[0030] The master alloy ingot is crushed and put into a quartz tube with a nozzle diameter of about 0.5 mm. The master alloy is heated to a molten state by induction melting in an Ar gas atmosphere, and then the alloy liquid is sprayed onto a high-speed rotating copper roller with high-pressure gas. , throw the strip at a speed of 35m / s to produce an alloy strip with a width of about 2mm and a thickness of about 20...

Embodiment 2

[0033] Example 2: Fe 25 co 25 Ni 25 Si 10 B 15

[0034] The specific implementation steps are the same as in Example 1, and the critical diameter of the high-entropy bulk amorphous alloy is finally prepared with a critical diameter of 1 mm. The relevant data are listed in Table 1.

Embodiment 3

[0035] Example 3: Fe 25 co 25 Ni 25 P 5 Si 7.5 B 12.5

[0036] Step 1. Ingredients

[0037] Using Fe, Co, Ni, Si, B and Fe with a purity greater than 99.5wt% 3 P raw materials are weighed and proportioned according to the nominal composition;

[0038] Step 2: Master alloy ingot smelting

[0039] Preparation of master alloy ingots by medium frequency or high frequency induction melting: put the raw materials into the crucible of induction melting furnace, and melt them three times under Ar gas atmosphere to obtain master alloy ingots with uniform composition;

[0040] All the other implementation steps are the same as steps three and four in embodiment 1.

[0041] The final prepared high-entropy bulk amorphous alloy has a critical diameter of 1.5 mm, and the relevant data are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com