Method for promoting crystallization of all-inorganic perovskite quantum dots in glass by adding fluoride

A fluoride and quantum dot technology, applied in the field of solid luminescent materials, can solve the problems of a large amount of components volatilizing, it is difficult to effectively precipitate quantum dots, etc., and achieve the effects of high quantum efficiency, excellent long-term stability and good transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: SiO 2 , B 2 o 3 , ZnO, Cs 2 CO 3 , PbBr 2 , NaBr and CaF 2 According to 40SiO 2 :20B 2 o 3 :10ZnO:15Cs 2 CO 3 :10PbBr 2 :5NaBr:5CaF 2 The ratio of (molar ratio) is accurately weighed, ground evenly in an agate mortar, placed in a crucible, heated to 1150°C in a resistance furnace for 15 minutes, and then quickly poured molten glass into a copper mold for molding; Then the glass continues to be heated and kept at 520°C for 2 hours to make it crystallize to obtain CsPbBr 3 Embedded perovskite quantum dot glass material.

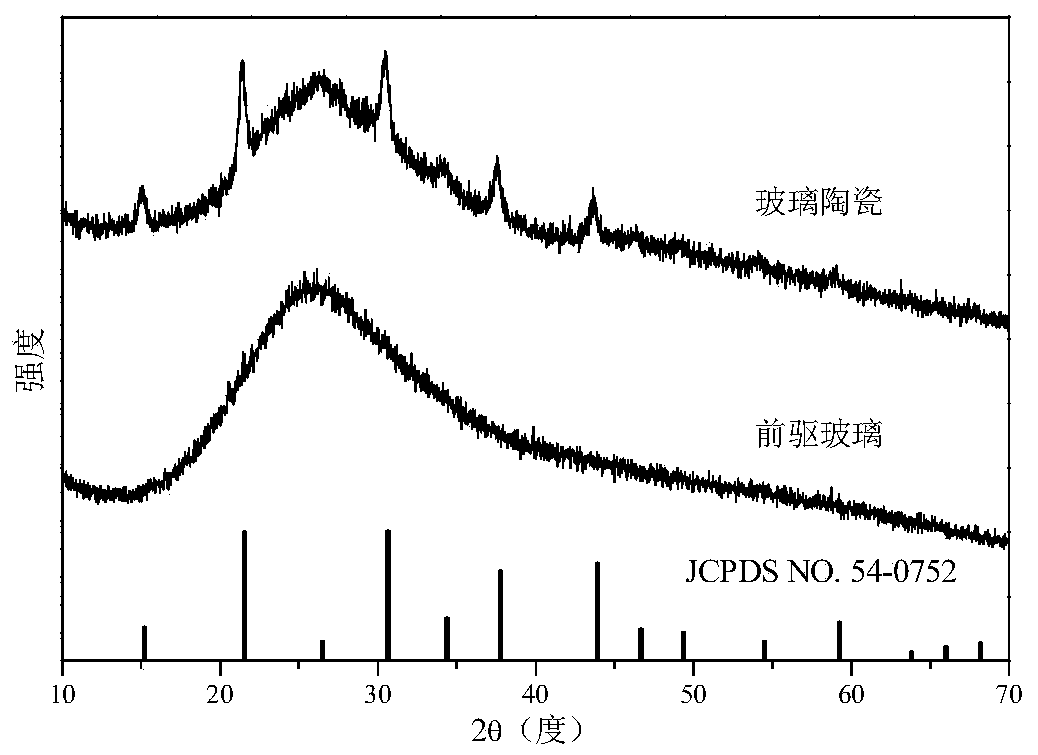

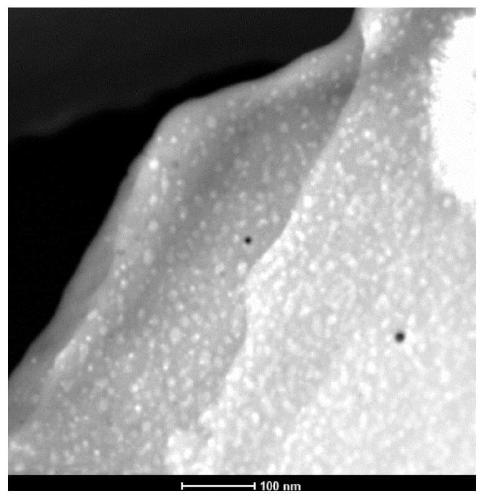

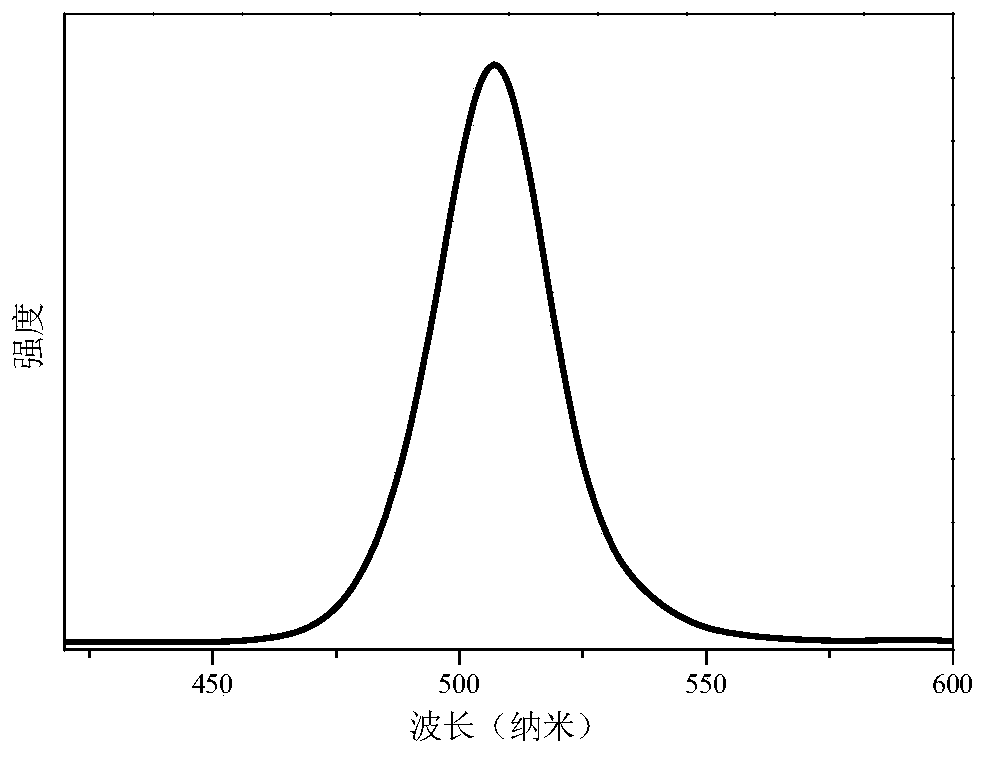

[0023] The X-ray diffraction pattern shows that the precursor glass is a typical amorphous structure, and the cubic structure CsPbBr is precipitated in the borosilicate glass substrate after heat treatment 3 quantum dots ( figure 1 ), the transmission electron microscope observation shows that there are a large number of CsPbBr with a size of about 10nm uniformly distributed in the glass 3 Grain ( figure 2 ), the integral ...

Embodiment 2

[0024] Embodiment 2: SiO 2 , B 2 o 3 , ZnO, Cs 2 CO 3 , PbBr 2 , NaBr and NH 4 F according to 40SiO 2 :20B 2 o 3 :10ZnO:15Cs 2 CO 3 :10PbBr 2 :5NaBr:20NH 4 The proportion of F (molar ratio) is accurately weighed, ground evenly in an agate mortar, placed in a crucible, heated to 1150°C in a resistance furnace for 8 minutes, and then the molten glass is quickly poured into a copper mold for molding ; Then the glass is heated and kept at 480°C for 6 hours to make it crystallize, and obtain CsPbBr 3 Embedded with perovskite quantum dot glass material, the sample emits bright green light under the irradiation of ultraviolet light.

Embodiment 3

[0025] Embodiment 3: SiO 2 , B 2 o 3 , ZnO, Cs 2 CO 3 , PbBr 2 , NaBr and YF 3 According to 40SiO 2 :20B 2 o 3 :10ZnO:15Cs 2 CO 3 :10PbBr 2 :5NaBr:10YF 3 The ratio of (molar ratio) is accurately weighed, ground evenly in an agate mortar, placed in a crucible, heated to 1150°C in a resistance furnace for 8 minutes, and then quickly poured molten glass into a copper mold for molding; Then the glass continues to be heated and kept at 480°C for 2 hours to make it crystallize to obtain CsPbBr 3 Embedded with perovskite quantum dot glass material, the sample emits bright green light under the irradiation of ultraviolet light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com