Amorphous nickel-free zirconium alloy

a nickel-free zirconium alloy and nickel-free technology, applied in the field of amorphous alloys (or metallic glass), to achieve the effects of high fracture toughness, high strength and easy formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

exemplary embodiment 1

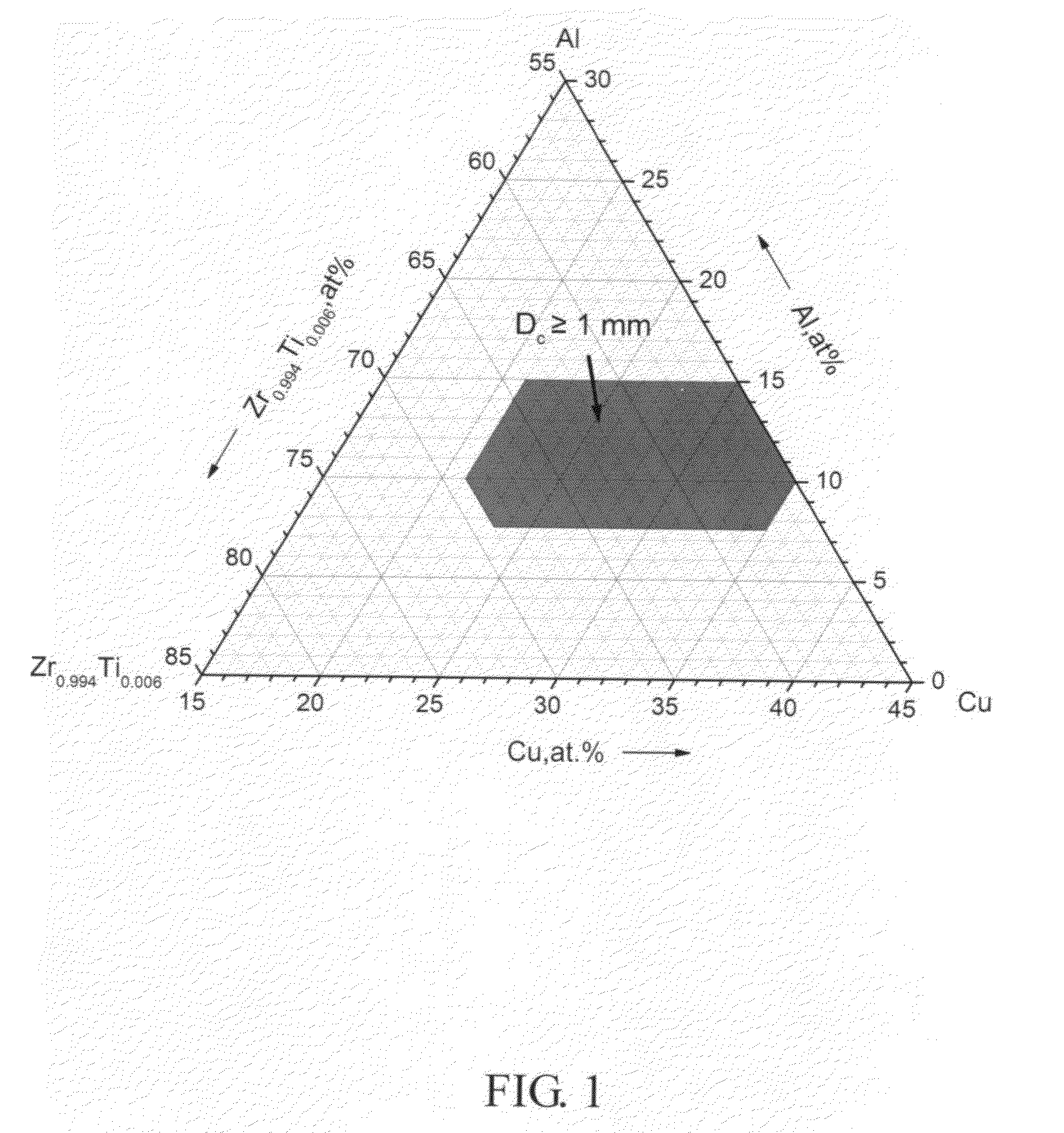

b>2.1Cu25Al12 Alloy (Numeric References Refer to Atomic Percentage)

[0043]The starting materials are pure Zr, Ti, Cu, Al in the forms of rod, bulk, ingot, sheet brought in the market (the purity is higher than 99.5% in percentage weight), which are processed under Ti-gettered argon atmosphere in a water-cooled copper hearth by arc melting to form a quaternary master alloy ingot. The master alloy ingot is melted for several times in order to ensure compositional homogeneity. Place 55 g master alloy ingot in a water-cooled copper crucible. Arc melting the ingot to a temperature which is higher than the melting point for forming an alloy melt. After melting, turning the copper crucible to pour the alloy melt to a copper mold for casting. The copper mold has an inner cavity with a preset size of φ10 mm×110 mm (other dimension with different diameter and length or various geometry can also be selected). After cooling, the alloy melt forms an alloy rod with a diameter of 10 mm and a length...

exemplary embodiment 2

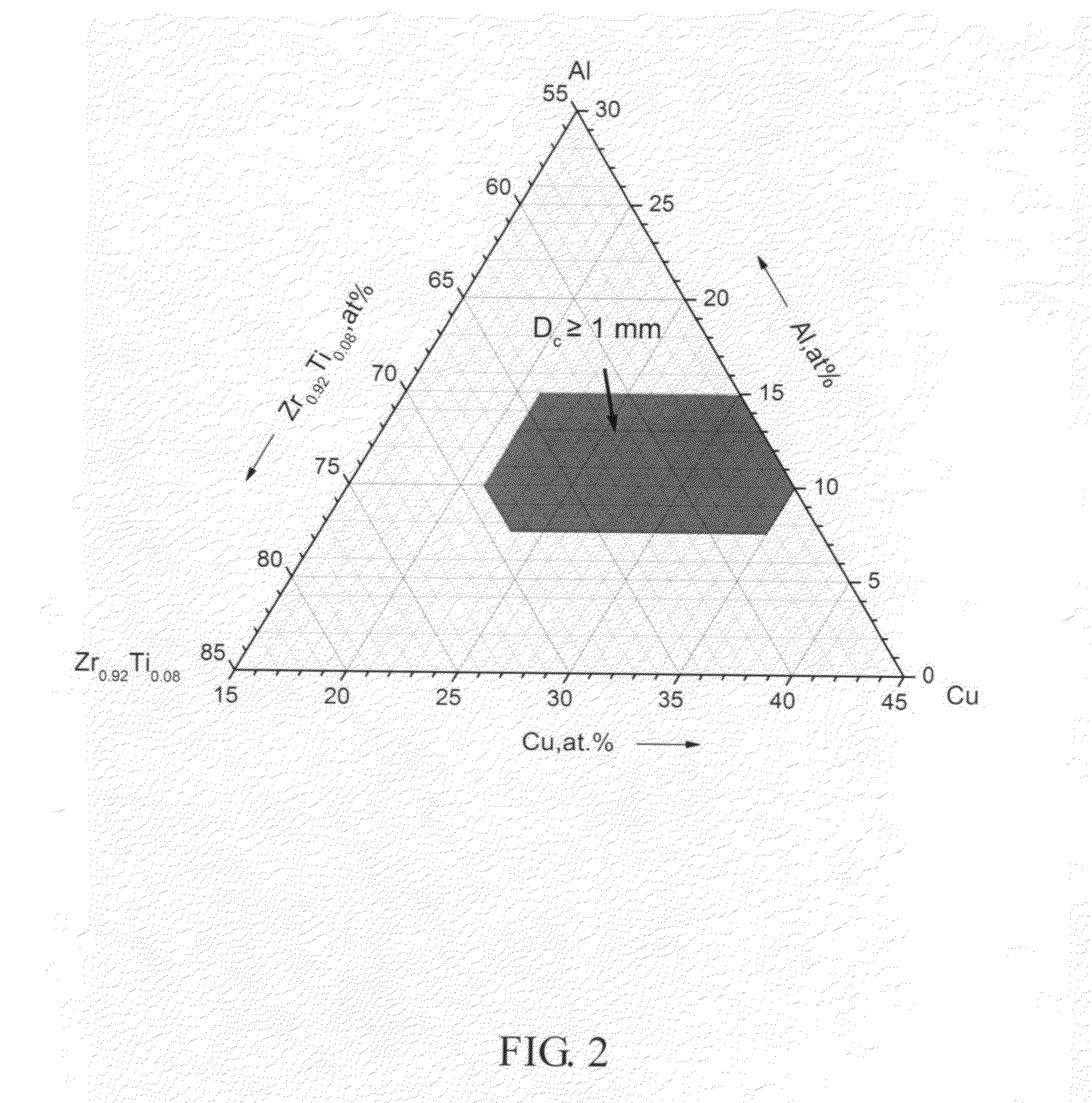

b>4.4Cu24Al10 Alloy

[0044]The starting materials are pure Zr, Ti, Cu, Al in the forms of rod, bulk, ingot, sheet brought in the market (the purity is higher than 99.5% in percentage weight), which are processed under Ti-gettered argon atmosphere in a water-cooled copper hearth by arc melting to form a quaternary master alloy ingot. The master alloy ingot is melted for several times in order to ensure compositional homogeneity. Place 40 g master alloy ingot in a water-cooled copper crucible. Arc melting the ingot to a temperature which is higher than the melting point for forming an alloy melt. After melting, turning the copper crucible to pour the alloy melt to a copper mold for casting. The copper mold has an inner cavity with a preset size of φ8 mm×110 mm (other dimension with different diameter and length or various geometry can also be selected). After cooling, the alloy melt forms an alloy rod with a diameter of 8 mm and a length of 70 mm. The cross-section of the alloy rod is p...

exemplary embodiment 3

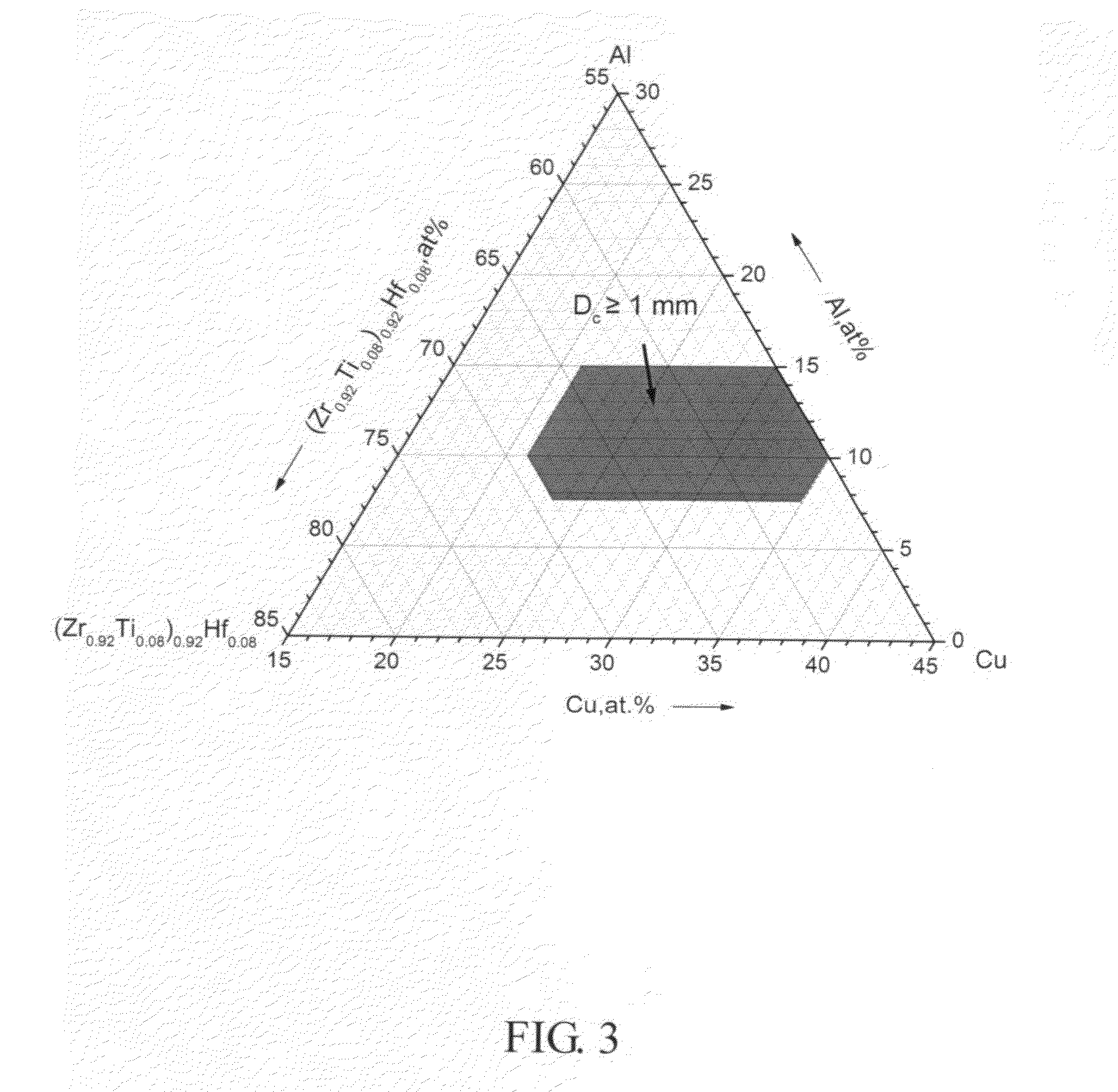

ub>2.02Hf2.52Cu25Al12 Alloy

[0045]The starting materials are pure Zr, Ti, Cu, Al, Hf in the forms of rod, bulk, ingot, sheet brought in the market (the purity is higher than 99.5% in percentage weight), which are processed under Ti-gettered argon atmosphere in a water-cooled copper hearth by arc melting to form a quinary master alloy ingot. The master alloy ingot is melted for several times in order to ensure compositional homogeneity. Place 55 g master alloy ingot in a water-cooled copper crucible. Arc melting the ingot to a temperature which is higher than the melting point for forming an alloy melt. After melting, turning the copper crucible to pour the alloy melt to a copper mold for casting. The copper mold has an inner cavity with a preset size of φ10 mm×110 mm (other dimension with different diameter and length or various geometry can also be selected). After cooling, the alloy melt forms an alloy rod with a diameter of 10 mm and a length of 70 mm. The cross-section of the all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com