Wave type inclined plate vibration device for preparing semisolid state alloy and preparation method thereof

A vibrating device and wave-shaped technology, which is applied in the field of preparing semi-solid alloys, achieves the effect of improving the effect of stirring, short process flow and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

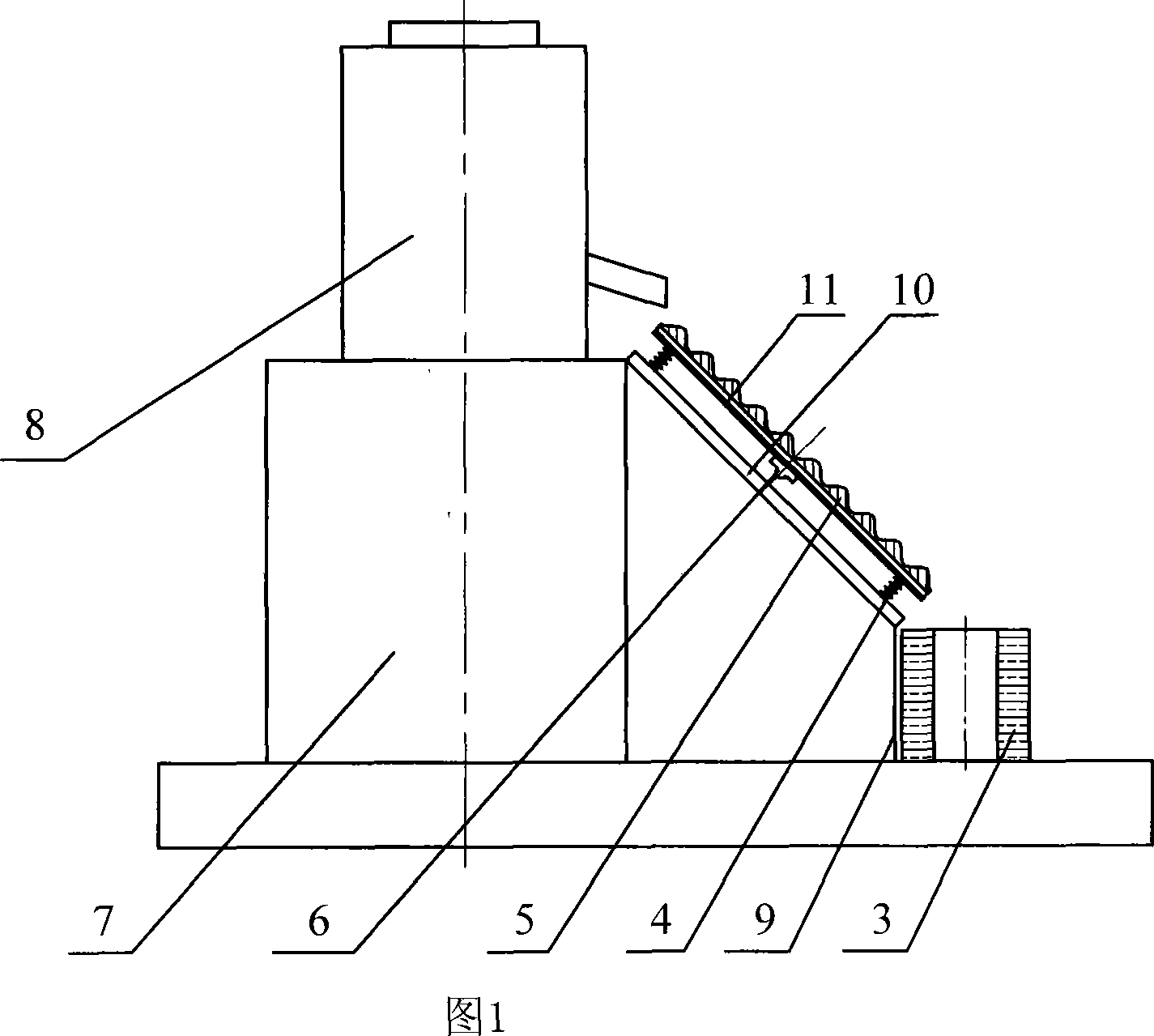

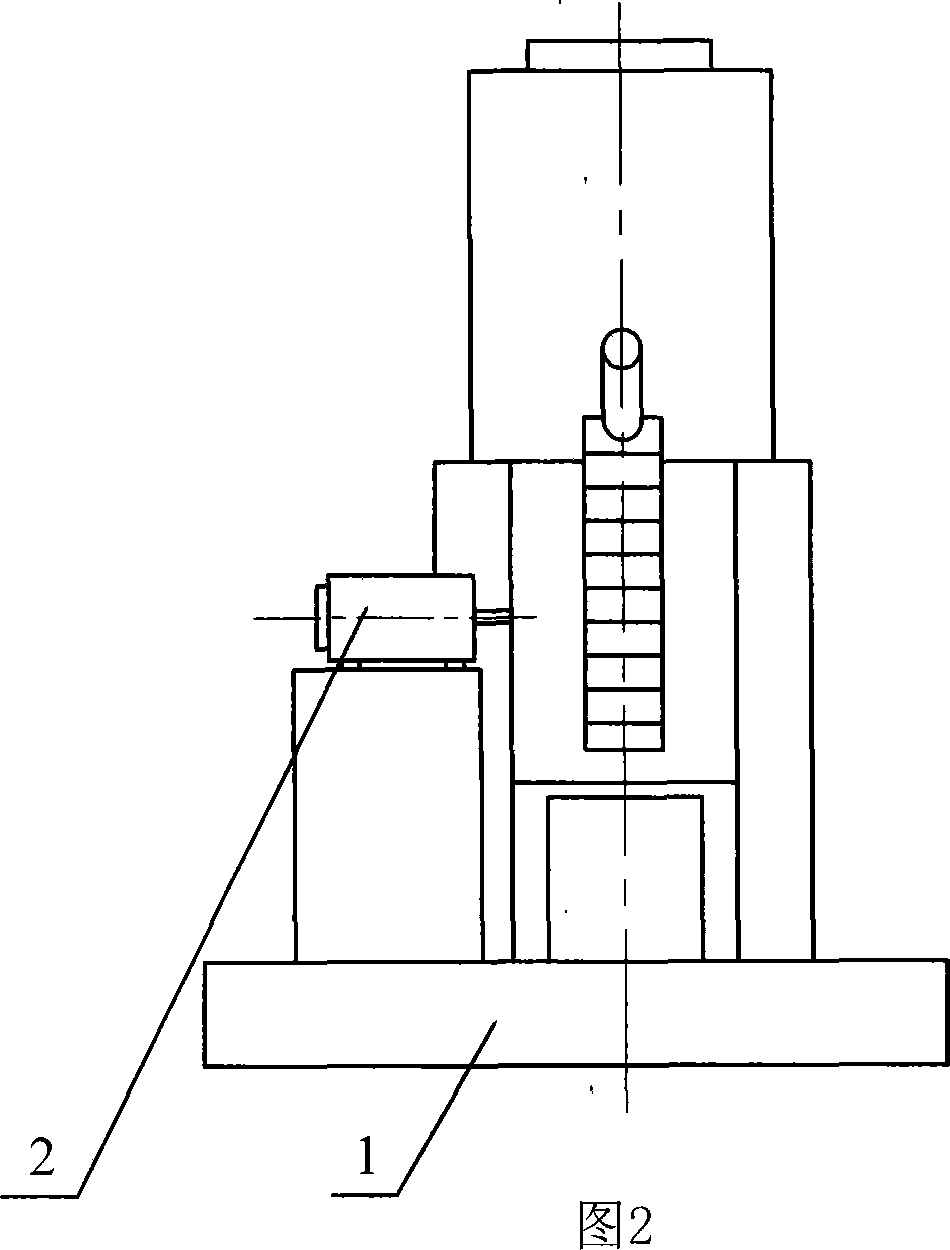

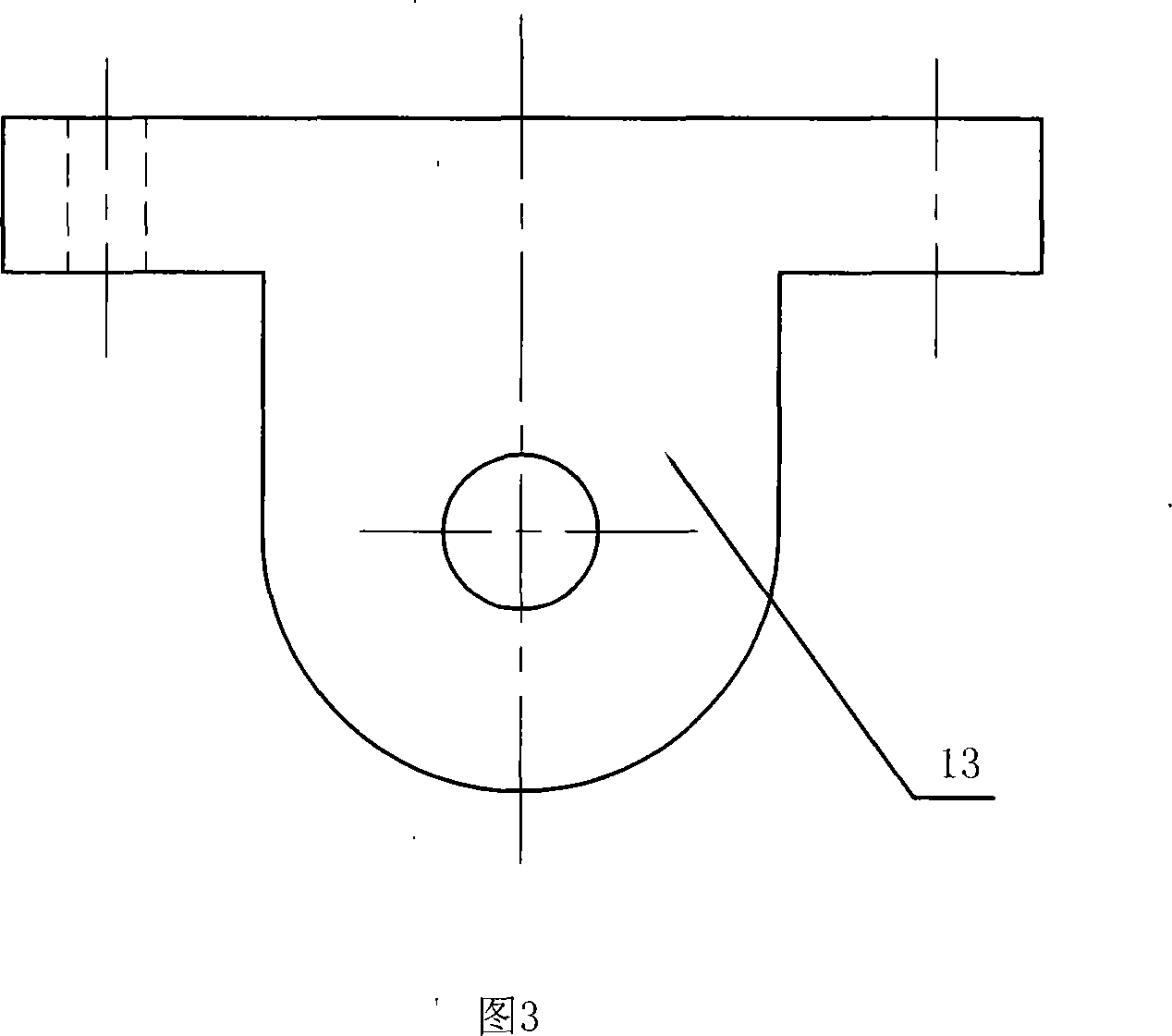

[0017] Embodiment 1: as shown in Fig. 1, Fig. 2, wave type inclined plate vibration device of the present invention comprises support 7, wave type metal plate 5, cam vibration mechanism 6, water-cooled copper mold 3, motor 2 and frequency modulation device, support 7 It is fixed on the concrete floor by anchor bolts to prevent resonance during vibration. The resonance voltage is 150V. A tundish 8 is fixed on the bracket 7. A support plate 9 is fixed parallel to the support plate 7. The side of the support plate 9 is water-cooled copper. Die 3, the fixed plate 10 that is used to fix the corrugated metal plate 5 is installed between the support plate 9 and the support 7, the fixed plate 10 connects the bracket 11 of the corrugated metal plate 5 by the spring 4, and the bracket 11 of the corrugated metal plate 5 A cam mechanism 6 is fixed on the frame 11, and the cam mechanism 6 and the motor 2 are softly connected by a steel wire rope with a rubber hose, and the motor is connecte...

Embodiment 2

[0024] Embodiment 2: the device of this example is the same as that of embodiment 1, and the preparation process of using this device to prepare Al6Si2Mg alloy semi-solid slurry and blank comprises the following steps:

[0025] (1) Put industrial pure aluminum and industrial Al-Si alloy in the crucible in the box-type resistance furnace to heat, after melting, control the melt temperature with a temperature control cabinet;

[0026] (2) When the temperature of the melt reaches 750°C, stop heating, wrap 1.8% pure Mg with aluminum foil, dry and press it into the Al-Si alloy melt for heating and melting;

[0027] (3) After all the melting reactions, stop heating, and when the temperature of the melt drops to 720°C, add 0.3% slag remover C 2 Cl 6 Wrap it with aluminum foil and dry it and press it into the bottom of the melt. In this case, the slag remover C 2 Cl 6 0.3%, for degassing and slag removal refining treatment of alloy melt;

[0028](4) When the temperature is 675°C, ...

Embodiment 3

[0029] Embodiment 3: the device of this example is the same as that of embodiment 1, and the preparation process of using this device to prepare Al6Si2Mg alloy semi-solid slurry and blank comprises the following steps:

[0030] (1) Put industrial pure aluminum and industrial Al-Si alloy in the crucible in the box-type resistance furnace to heat, after melting, control the melt temperature with a temperature control cabinet;

[0031] (2) When the temperature of the melt reaches 750° C., stop heating, wrap 2% pure Mg with aluminum foil, dry and press it into the Al-Si alloy melt for heating and melting;

[0032] (3) After all the melting reactions, stop heating, and when the temperature of the melt drops to 720°C, add 0.5% slag remover C 2 Cl 6 Wrap it with aluminum foil and dry it, then press it into the bottom of the melt, and carry out the degassing and slag removal refining treatment of the alloy melt;

[0033] (4) When the temperature is 675°C, after standing still for 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com