Tin-alloy powder for preparing electronic grade silver-bearing high strength lead-free solder paste

A lead-free solder and tin alloy technology, applied in the field of tin alloy powder, can solve problems such as cracking of solder joints, insufficient impact resistance, poor electrical properties of products, etc., and achieve the effect of firm solder joints and good ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

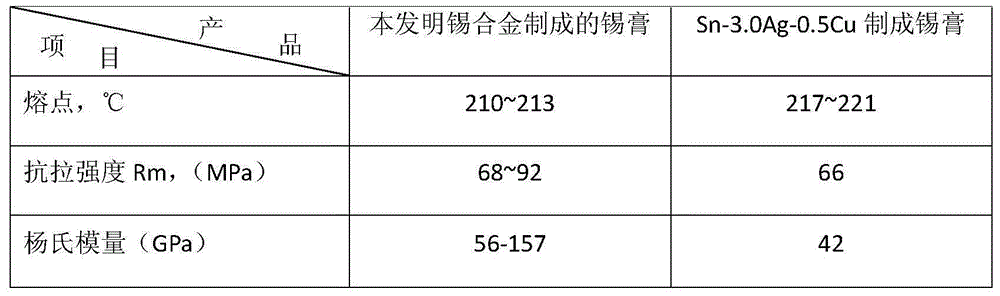

[0016] Take Ag2.0kg, Cu0.5kg, Bi1.5kg, Ce0.07kg, Nd0.007kg and the balance Sn95.923kg to make 45 micron tin alloy powder, take the above tin alloy powder 88kg and flux 12kg to make silver-containing high-strength Lead-free solder paste, test results are shown in Table 2.

Embodiment 2

[0018] Take Ag2.5kg, Cu0.7kg, Bi2.5kg, Ce0.08kg, Nd0.005kg and the balance Sn94.215kg to make 35 micron tin alloy powder, take the above tin alloy powder 88kg and flux 12kg to make silver-containing high-strength Lead-free solder paste, test results are shown in Table 2.

Embodiment 3

[0020] Take Ag3.0kg, Cu0.8kg, Bi3.5kg, Ce0.03kg, Nd0.003kg and the balance Sn92.667kg to make 25 micron tin alloy powder, take the above tin alloy powder 88kg and flux 12kg to make silver-containing high-strength Lead-free solder paste, test results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com