Steel safety shell welding technology without post weld heat treatment

A technology for steel containment and post-weld heat treatment, which is used in manufacturing tools, welding equipment, welding accessories, etc., can solve problems such as difficult to control heat treatment temperature, inability to solve on-site electric power, and inability to follow post-weld heat treatment, so as to reduce construction hidden dangers , the mechanical properties are satisfied, the effect of reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

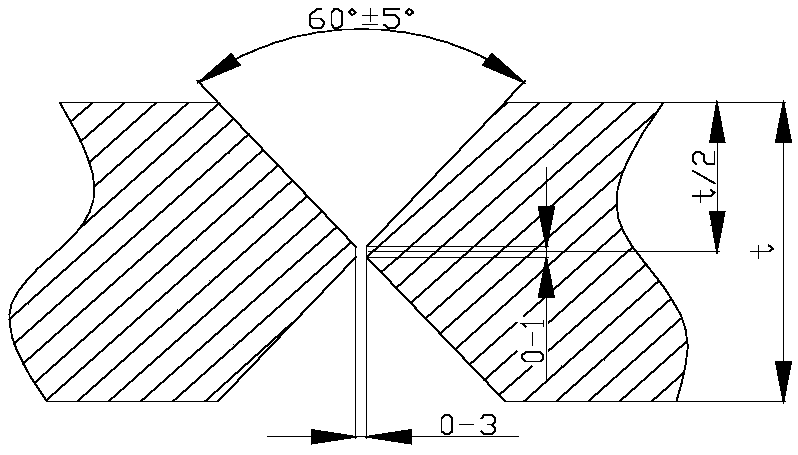

[0026] In view of the large volume of the steel containment in the on-site installation of the nuclear power plant, and certain difficulties and potential safety hazards in the on-site post-weld heat treatment, the present invention provides a reasonable welding process for exempting the post-weld heat treatment of the 60mm thick SA 738Gr. It meets the requirements of the production process that requires post-weld heat treatment for the nominal wall thickness of nuclear power plant steel containment vessels greater than 44mm and less than or equal to 60mm.

[0027] Such as figure 1 As shown, the role of post-weld heat treatment has two aspects: 1) to improve the mechanical properties of welded joints; 2) to reduce the residual str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com