Alkaline cyanide-free brush plating solution for multielement coordination system and preparation method of alkaline cyanide-free brush plating solution

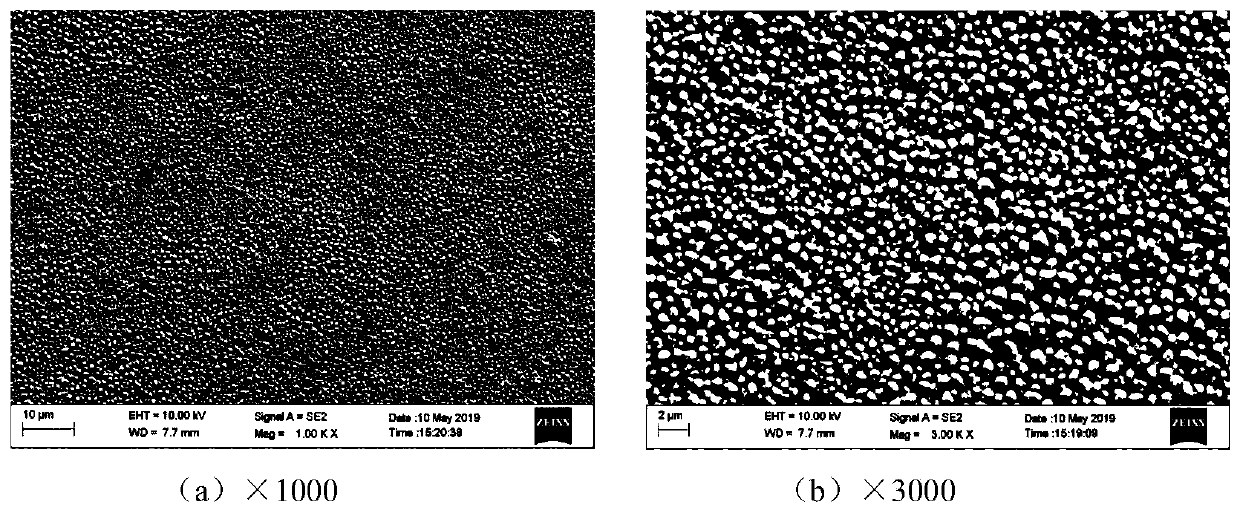

A technology of brush plating and coordination, applied in the field of brush plating, can solve the problem of easy yellowing and discoloration of the coating, and achieve the effect of good bonding and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of alkaline cyanide-free electric brush plating solution of multiple coordination system, comprises solvent water and following component:

[0043] AgNO 3 90g / L, 260g / L succinimide, 180g / L 5,5-dimethylhydantoin, 120g / L potassium pyrophosphate, 30g / L ammonium acetate, 250g / L potassium methanesulfonate, Potassium carbonate 25g / L, bismuth nitrate 2g / L, bipyridine 1g / L, thiosemicarbazide 0.8g / L, adjust the pH of the plating solution to be 9.

[0044] The preparation method of the alkaline cyanide-free brush plating solution of this multiple coordination system comprises the steps:

[0045] Mix and dissolve alkali, succinimide and 5,5-dimethylhydantoin to obtain a mixed solution;

[0046] Under stirring, slowly inject the silver nitrate solution into the mixed solution to obtain the second mixed solution;

[0047] Add potassium pyrophosphate and potassium methanesulfonate to the second mixed solution, dissolve completely, and add alkali to adjust the pH value of the...

Embodiment 2

[0052] A kind of alkaline cyanide-free electric brush plating solution of multiple coordination system, comprises solvent water and following component:

[0053] AgNO 3 80g / L, 300g / L succinimide, 100g / L 5,5-dimethylhydantoin, 80g / L potassium pyrophosphate, 160g / L potassium methanesulfonate, 40g / L ammonium acetate, Potassium carbonate 30g / L, bismuth nitrate 3g / L, bipyridine 0.8g / L, thiosemicarbazide 1.0g / L, adjust the pH of the plating solution to be 8.5.

[0054] The preparation method of the alkaline cyanide-free brush plating solution of multiple coordination system comprises the steps:

[0055] Mix and dissolve alkali, succinimide and 5,5-dimethylhydantoin to obtain a mixed solution;

[0056] Under stirring, slowly inject the silver nitrate solution into the mixed solution to obtain the second mixed solution;

[0057] Add potassium pyrophosphate and potassium methanesulfonate to the second mixed solution, dissolve completely, and add alkali to adjust the pH value of the...

Embodiment 3

[0060] A kind of alkaline cyanide-free electric brush plating solution of multiple coordination system, comprises solvent water and following component:

[0061] AgNO 3 160g / L, 240g / L succinimide, 200g / L 5,5-dimethylhydantoin, 160g / L potassium pyrophosphate, 320g / L potassium methanesulfonate, 15g / L ammonium acetate, Potassium carbonate 15g / L, bismuth nitrate 1.5g / L, bipyridine 1.2g / L, thiosemicarbazide 1.0g / L, adjust the pH of the plating solution to be 10.

[0062] The preparation method of the alkaline cyanide-free brush plating solution of multiple coordination system comprises the steps:

[0063] Mix and dissolve alkali, succinimide and 5,5-dimethylhydantoin to obtain a mixed solution;

[0064] Under stirring, slowly inject the silver nitrate solution into the mixed solution to obtain the second mixed solution;

[0065] Add potassium pyrophosphate and potassium methanesulfonate to the second mixed solution, dissolve completely, and add alkali to adjust the pH value of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com