High toughness ring chain steel for mine and method for producing the same

A mining ring chain, high-strength and toughness technology, applied in the direction of temperature control, can solve the problems of uneven structure, low-strength plastic matching, poor and other problems, and achieve the effect of uniform and meticulous structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below through specific examples.

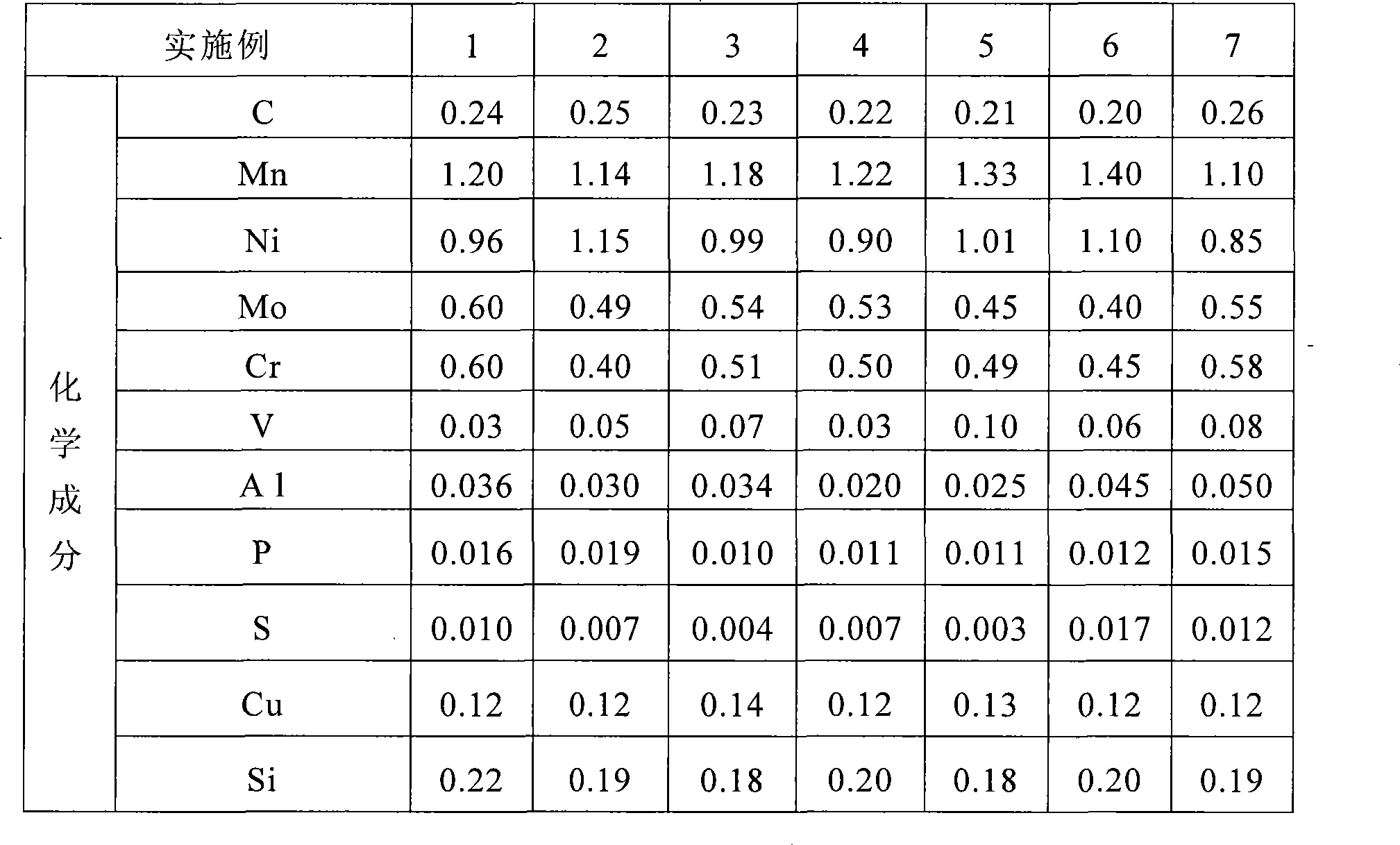

[0039] The chemical compositions of the examples of the present invention are shown in Table 2.

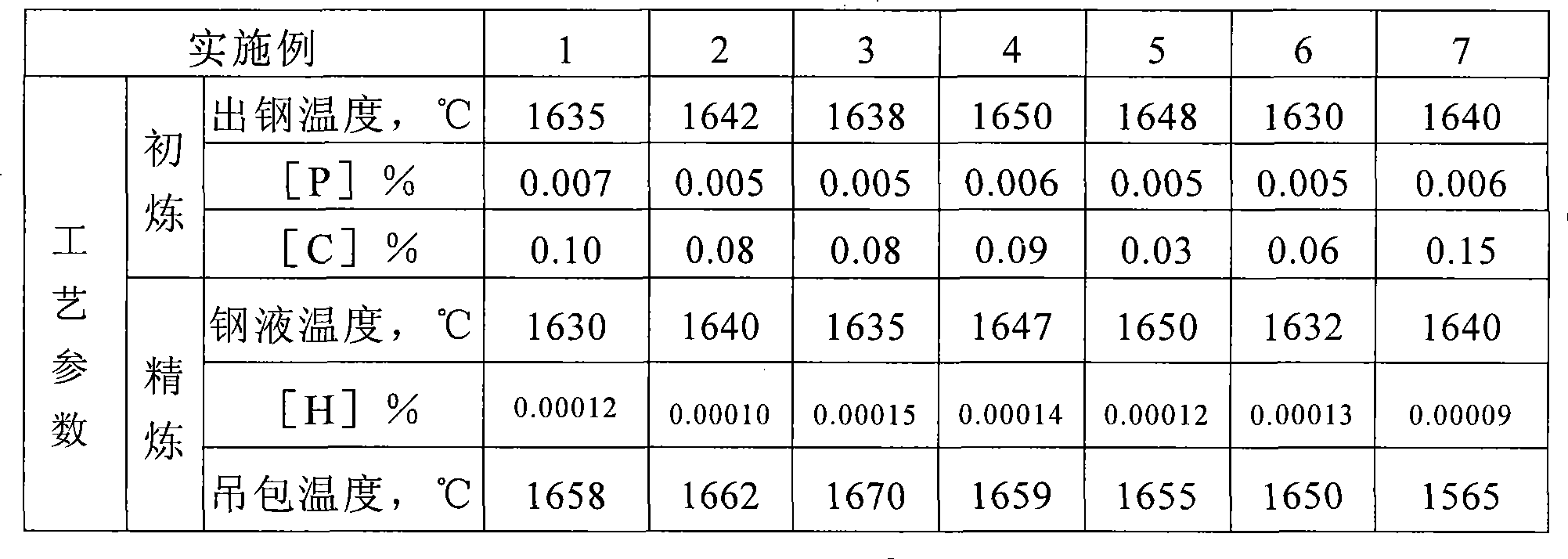

[0040] The preparation method of the embodiment of the present invention adopts a three-step technological process: the first step: primary smelting in electric arc furnace→vacuum refining in ladle furnace→continuous casting; Rod annealed. The specific process conditions are shown in Table 3.

[0041] The performance of the embodiment of the present invention is shown in Table 4.

[0042] The chemical composition of table 2 embodiment steel bar, wt%

[0043]

[0044] table 3

[0045]

[0046]

[0047] Table 4

[0048]

[0049] Table 5 is the contrast result of product performance of the present invention and the mechanical property index of national standard requirement and imported material requirement:

[0050] table 5

[0051]

tensile strength

MPa Yi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com