Manufacturing method for silicon-contained aluminum alloy welding wire rod for spaceflight

A silicon-aluminum alloy and manufacturing method technology, which is applied in the direction of manufacturing tools, welding/cutting media/materials, welding media, etc., can solve the problems of prone to pores, slag inclusions and cracks, poor internal structure, etc., and achieve uniform and fine structure. Uniform structure and good formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

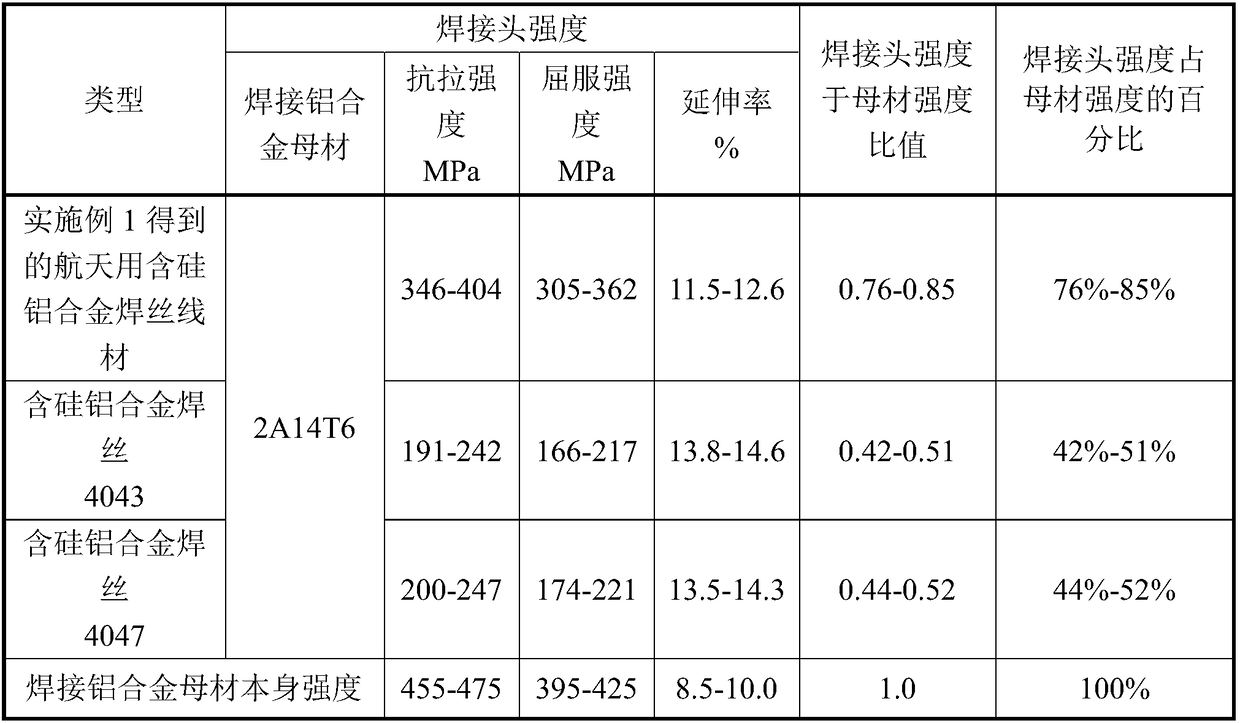

Examples

specific Embodiment approach 1

[0016] Specific implementation mode 1: This implementation mode is a manufacturing method of silicon-containing aluminum alloy welding wire for aerospace, which is specifically completed according to the following steps:

[0017] 1. Melting: According to the mass fraction of Si in the silicon-containing aluminum alloy welding wire is 3.0%-4.0%, the mass fraction of Cu is 1.5%-2.8%, the mass fraction of Cr is 0.001%-0.08%, and the mass fraction of V is 0.05%~0.20%, the mass fraction of Be is 0.0001%~0.0015%, the mass fraction of Ti is 0.08%~0.18%, the mass fraction of Zr is 0.08%~0.28%, the mass fraction of impurities is ≤0.1%, and the balance is Al weighs low magnesium aluminum alloy ingots, copper ingots, silicon aluminum alloys, chromium aluminum alloys, vanadium aluminum alloys, zirconium aluminum alloys, beryllium aluminum alloys and titanium aluminum alloys, and low magnesium aluminum alloy ingots, copper ingots, silicon aluminum alloys, Chromium-aluminum alloy, vanadium-...

specific Embodiment approach 2

[0027] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step one, the mass fraction of Si in the silicon-containing aluminum alloy welding wire is 3.5%, the mass fraction of Cu is 2.05%, and the mass fraction of Cr is 0.02%, the mass fraction of V is 0.10%, the mass fraction of Be is 0.0006%, the mass fraction of Ti is 0.11%, the mass fraction of Zr is 0.13%, and the balance is Al. Weigh low-magnesium aluminum alloy ingots, copper ingots, Silicon-aluminum alloys, chrome-aluminum alloys, vanadium-aluminum alloys, zirconium-aluminum alloys, beryllium-aluminum alloys, and titanium-aluminum alloys. Others are the same as the first embodiment.

specific Embodiment approach 3

[0028] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: in step 1, melt at a temperature of 740° C. for 5.5 hours to obtain a silicon-containing aluminum alloy melt. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com