Selenium-enriched nutritious instant coarse cereal powder and preparation method thereof

A technology of instant powder and miscellaneous grains, which is applied in the field of deep processing of food, can solve the problems of rough taste, poor solubility, and single nutrition, and achieve the effects of better taste, strong instant solubility and comprehensive and balanced nutrition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

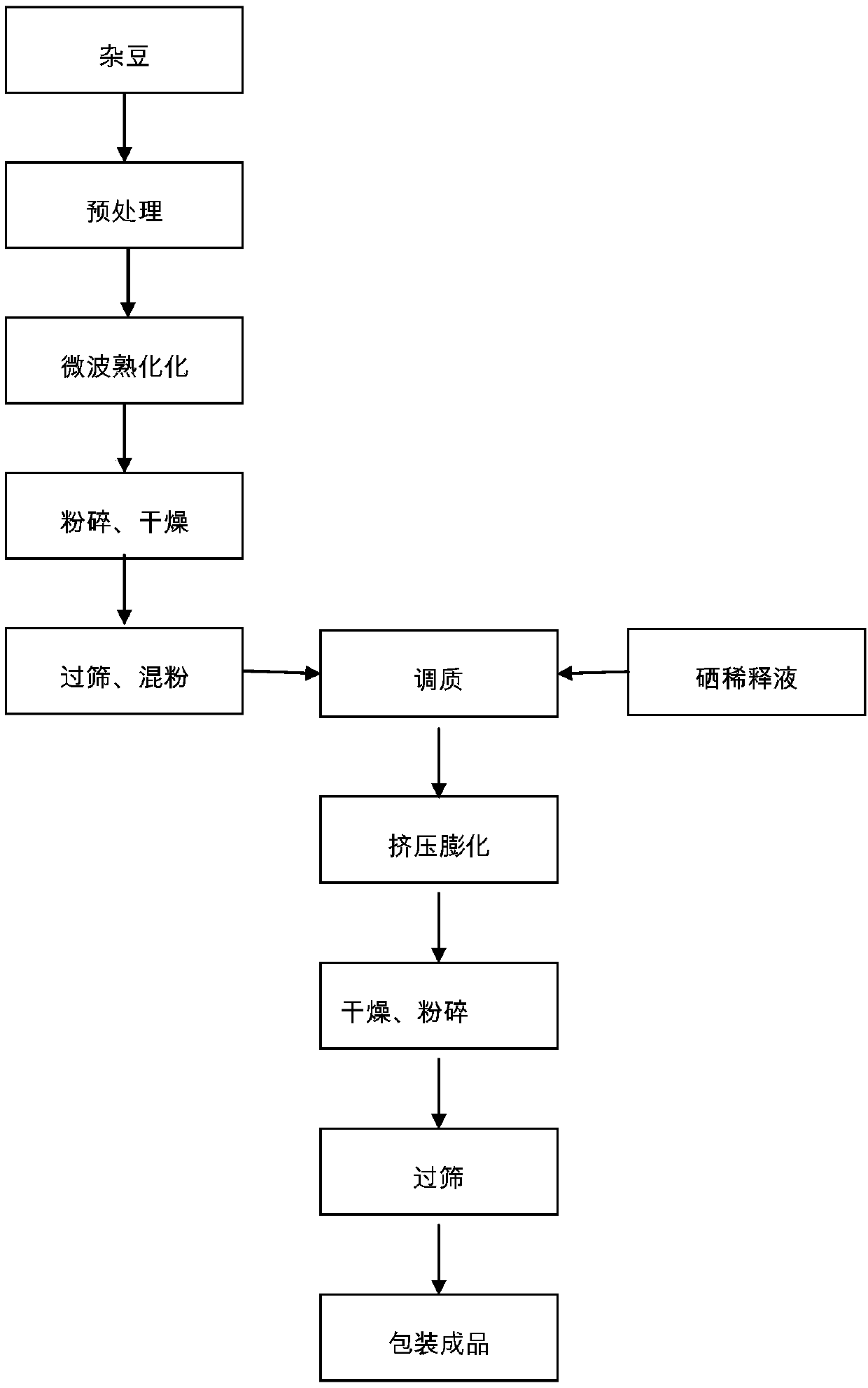

Method used

Image

Examples

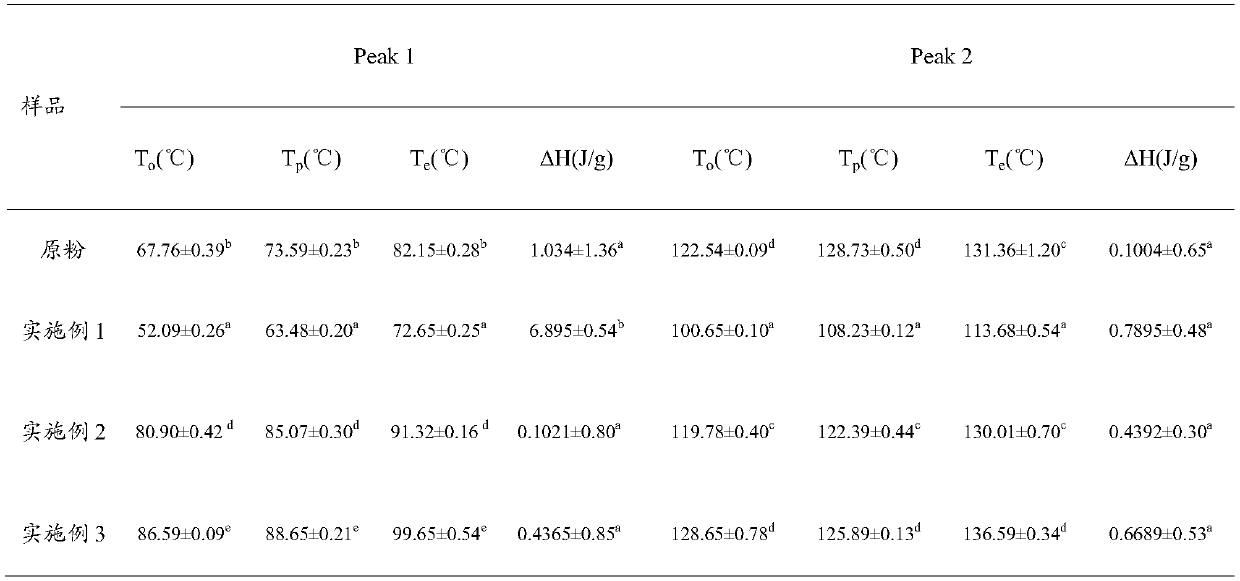

Embodiment 1

[0031] Soybean, green bean, broad bean, pea, mung bean, black bean, coix seed, lotus seed and red bean are cleaned and decontaminated, then pre-cooked in a microwave power of 1000w, microwave for 10min, material layer thickness of 0.2cm, and the processed miscellaneous grains are passed through a grinder Crush to 125 microns, accurately weigh 10% of rice flour, 8% of soybean flour, 8% of green bean flour, 8% of broad bean flour, 8% of pea flour, 8% of mung bean flour, 8% of red bean flour, 8% of black bean flour, small 4% rice flour, 5% barley flour, 5% buckwheat flour, 5% taro powder, 1% lotus seed powder, 1% yam powder, 1% sesame powder, 1% highland barley, 1% saffron, 5% maltodextrin, milk powder 5% and 1% selenium diluent are mixed in the mixer, adjust the water content of the mixed material to 30%, and then send it to the twin-screw extruder for molding and granulation, and set the cavity of each section of the twin-screw extruder to work Temperature: Zone I 40°C, Zone II...

Embodiment 2

[0033]Soybean, green bean, pea, broad bean, mung bean, black bean, coix seed, lotus seed and red bean are cleaned and decontaminated, and then pre-cooked at a microwave power of 1250w, microwave for 7.5min, and material layer thickness of 0.15cm, and the processed miscellaneous grains are crushed Machine crushed to 150 microns, accurately weigh 10% of rice flour, 8% of soybean flour, 8% of green bean flour, 8% of broad bean flour, 8% of pea flour, 8% of mung bean flour, 8% of red bean flour, 8% of black bean flour, 4% millet powder, 5% barley powder, 5% buckwheat flour, 5% taro powder, 1% lotus seed powder, 1% yam powder, 1% sesame powder, 1% highland barley, 1% saffron, 5% maltodextrin, 5% of milk powder and 1% of selenium diluent are placed in the mixer and mixed, the moisture content of the mixed material is adjusted to 35%, and then sent to the twin-screw extruder for molding and granulation, and the cavities of each section of the twin-screw extruder are set Body working ...

Embodiment 3

[0035] Mung beans, black beans, coix seeds, lotus seeds, and red beans are cleaned and decontaminated, and then pre-cooked in a microwave power of 1500w, microwave for 5min, and a material layer thickness of 0.1cm. Rice flour 10%, soybean flour 8%, green bean flour 8%, broad bean flour 8%, pea flour 8%, mung bean flour 8%, red bean flour 8%, black bean flour 8%, millet flour 4%, barley flour 5% , buckwheat flour 5%, taro head flour 5%, lotus seed powder 1%, yam powder 1%, sesame powder 1%, barley 1%, saffron 1%, maltodextrin 5%, milk powder 5% and selenium diluent 1% Mix in a mixer, adjust the moisture content of the mixed material to 40%, and then send it to a twin-screw extruder for molding and granulation. Set the working temperature of each section of the twin-screw extruder: 60°C in zone I, 60°C in zone II Zone 100°C, Zone III 160°C, Zone IV 160°C, Zone V 60°C, Zone VI 40°C, the screw speed is 350rpm, extruded through a rectangular die hole, the extruded material is dried...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com