Portable full nutritional yoghurt for spaceflight, yoghurt sheet, and preparation method thereof

A full-nutrition, portable technology, applied in milk preparations, applications, dairy products, etc., can solve the problems of flavor and nutritional deterioration, not full nutrition, high lactose content, and achieve adjustable flavor, neat and smooth slice shape, and sour taste. sweet and palatable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Mix 85% skimmed milk and 15% carbohydrates, homogenize, super-high temperature instantaneous sterilization, and cool.

[0033] 2. Lactase enzymatic hydrolysis, the amount of enzyme added is 0.2g / kg, the temperature is 25℃, the enzymatic hydrolysis time is 1h, the pH value is 6.0, and the hydrolysis rate is 50%.

[0034] 3. Inoculation and fermentation, and the fermentation strains are Bifidobacterium bifidum, B. longum, B. adolescentis, L. acidophilus, Streptococcus thermophilus 1:1 :1:1:1 mixture, the inoculation amount is 0.1u fermented strain per kg of skimmed milk, fermented at 35°C for 20h, after fermentation, placed in a refrigerator at 5°C.

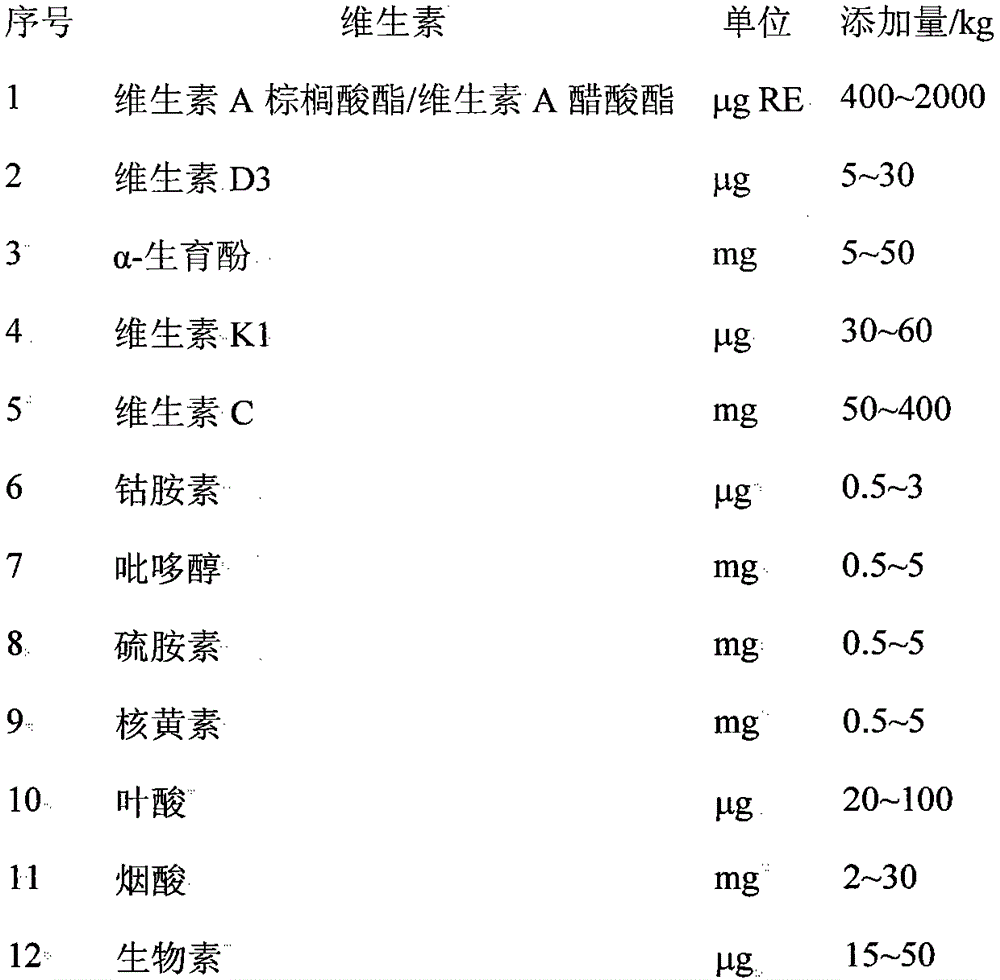

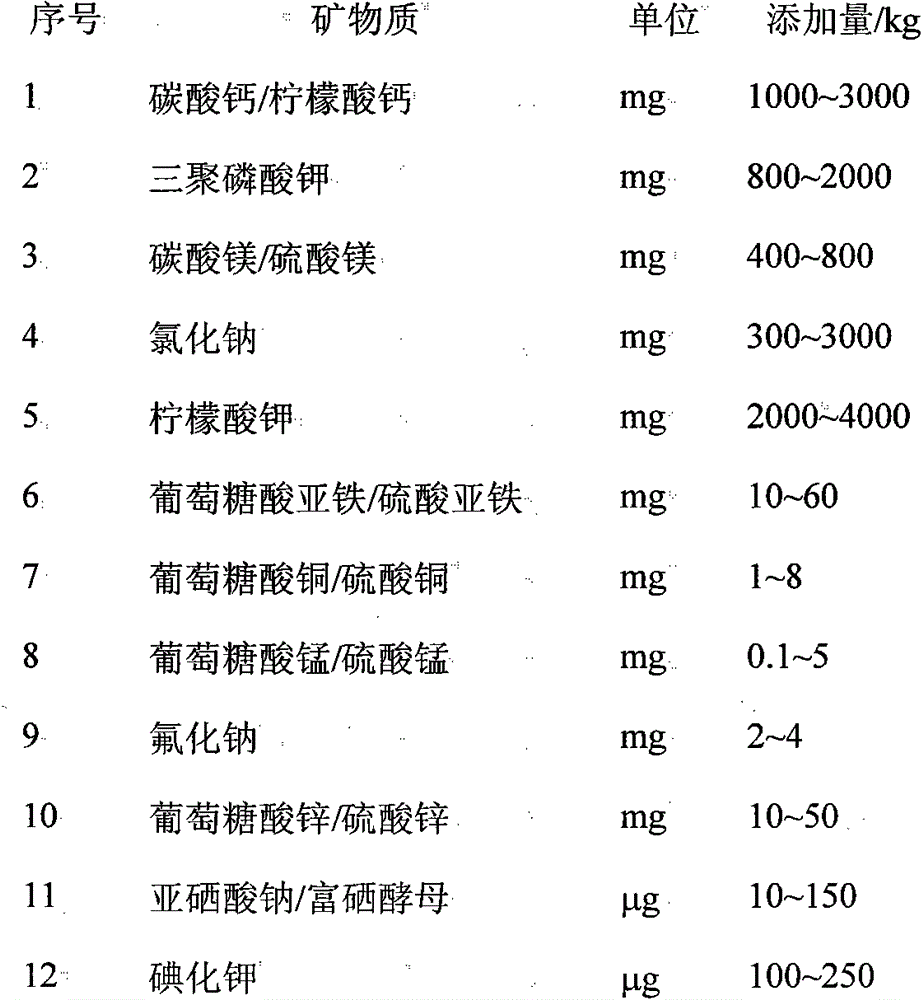

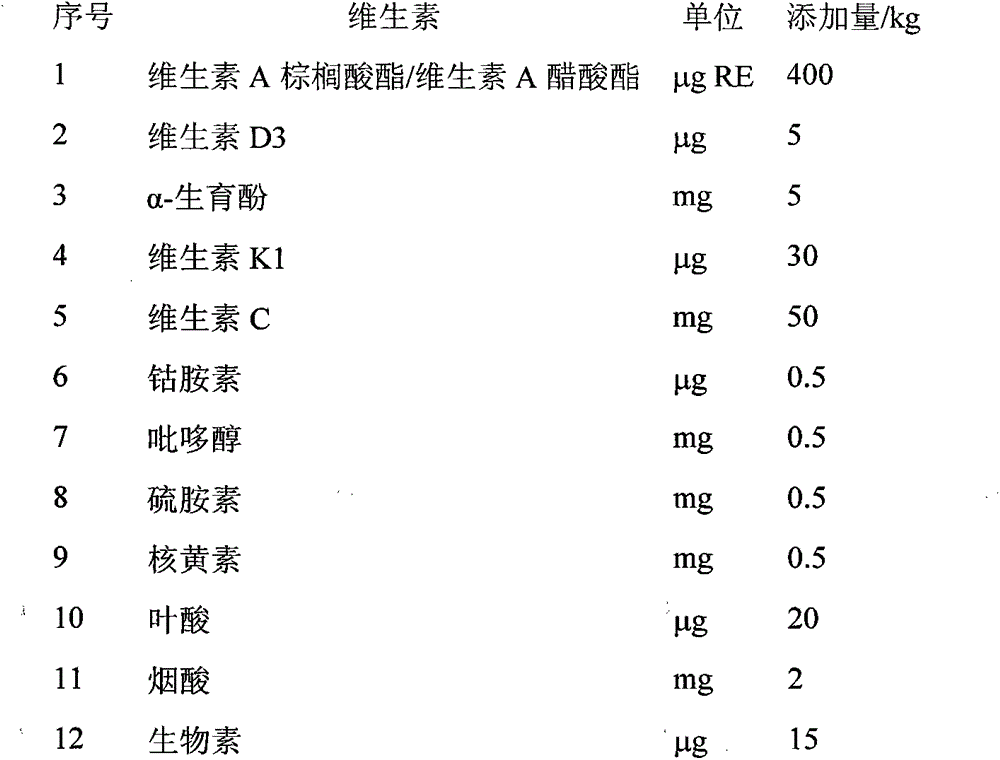

[0035] 4. Mix and mix, add the following components in order according to the weight ratio: multivitamin, multi mineral, taurine 0.001%, arginine 0.01%, coenzyme Q 10 0.001%, inositol 0.001%, L-carnitine 0.001%, nucleotide 0.001%, choline 0.01%, spirulina 0.05%, wheat dietary fiber 0.01%, composite emulsifier 0.01%, composite st...

Embodiment 2

[0055] 1. Mix 95% skimmed milk and 5% carbohydrates, homogenize, instantaneously sterilize at ultra-high temperature, and cool.

[0056] 2. Lactase enzymatic hydrolysis, enzyme addition amount is 2.0g / kg, temperature is 45℃, enzymolysis time is 5h, pH value is 7.5, hydrolysis rate is 80%.

[0057] 3. Inoculation fermentation, the fermentation strains are B. infantis B. infantis, B. breve B. breve, Lactobacillus. Bulgaricus, Lactobacillus casei subsp. casei and Lactobacillus reuteri Lactobacillus reuteri 1:1:1:1:1 mixture, the inoculation amount is 0.5u fermented strains per kg of skimmed milk, fermented at 42°C for 20h, after fermentation, placed in a refrigerator at 5°C.

[0058] 4. Mix and mix, add the following components in order according to the weight ratio: multi-vitamin, multi-mineral, taurine 0.05%, arginine 1%, coenzyme Q 10 0.02%, inositol 0.05%, L-carnitine 0.05%, nucleotide 0.05%, choline 0.05%, spirulina 0.5%, wheat dietary fiber 2%, compound emulsifier 0.03%, compound ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com