Compound extrusion preparation method of large-diameter high-quality tube blank or annular blank

A compound extrusion, large-diameter technology, used in the preparation and processing of tube blanks, the compound extrusion preparation of large-diameter and high-quality tube blanks or ring blanks, and the field of difficult-to-deform materials, which can solve the problem of coarse structure, poor structure uniformity, and forming force It can achieve the effect of uniform structure, small deformation resistance and small strain rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

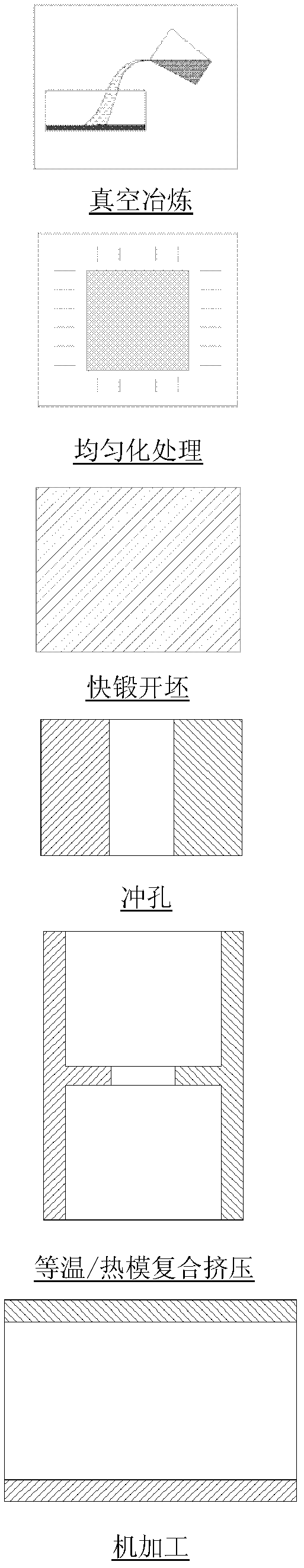

[0033] Such as figure 1 As shown, it is a process flow chart of the method for preparing large-diameter and high-quality tube billet or ring billet composite extrusion of the present invention. The composite extrusion preparation method of the present invention includes vacuum smelting, homogenization treatment, rapid forging billet opening, punching, and isothermal / Hot mold composite extrusion and machining, specifically include the following steps.

[0034](1) Vacuum smelting: vacuum smelting hard-to-deform materials such as nickel-based alloys, titanium alloys, high-strength steels or zirconium alloys to obtain alloy ingots; nickel-based alloys can be vacuum induction melting + electroslag remelting dual smelting process or Vacuum induction melting + electroslag remelting + vacuum consumable triple smelting process, high-strength steel can adopt vacuum induction melting + vacuum consumable dual smelting process, titanium alloy and zirconium alloy can adopt two or three vac...

Embodiment 1

[0041] According to the composition of In718 alloy, a vacuum induction furnace is used to smelt an electrode rod with a diameter of Φ300mm; after the surface of the electrode rod is polished and the riser is removed, an ingot with a diameter of Φ400mm is re-dissolved in an electroslag remelting furnace. The two-stage homogenization heat treatment process of In718 steel ingot is: 1160 ℃, heat preservation 24h and 1200 ℃, heat preservation 44h. Use ordinary carbon steel with a wall thickness of 10mm to wrap the homogenized In718 alloy ingot; put the wrapped ingot into the heating furnace, raise the temperature to 850°C, keep it for 2h, then raise the temperature to 1150°C, and keep it for 4h ;The billet is forged on the fast forging machine, and the forging is carried out for three fires, and the deformation of each fire is more than 70%, and it is rounded into a bar. A hollow blank with an outer diameter of Φ300mm and an inner diameter of 120mm. Preheat the prefabricated hollo...

Embodiment 2

[0043] According to the composition of the GH4698 alloy, the electrode rod with a diameter of Φ240mm was smelted in a vacuum induction furnace; after the surface of the electrode rod was polished and the riser was removed, the vacuum consumable electric arc furnace was used for secondary melting, and the diameter of the ingot was Φ320mm. Homogenization treatment process of GH4698 steel ingot: 1160°C, heat preservation for 60h. The homogenized GH4698 alloy ingot is sheathed by ordinary carbon steel with a wall thickness of 10 mm. Put the sheathed ingot into the heating furnace, raise the temperature to 860°C, keep it for 2 hours, then raise the temperature to 1200°C, and keep it for 4 hours; It is more than 70%, and it is rounded into a bar. After the forging bar is blanked, it is punched, forged and machined. It is prefabricated into a hollow blank with an outer diameter of Φ260mm and an inner diameter of 120mm. Prefabricate the hollow billet with a normal carbon steel ladle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com