Composite emulsifier with emulsification effect and water retention effect and application thereof

A technology for compounding emulsifier and function, applied in the field of food additives, can solve the problems of insufficient function of powder emulsifier, increased amount of emulsifier, and short action time, and achieves unique effect, improved product taste and texture. Even and delicate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

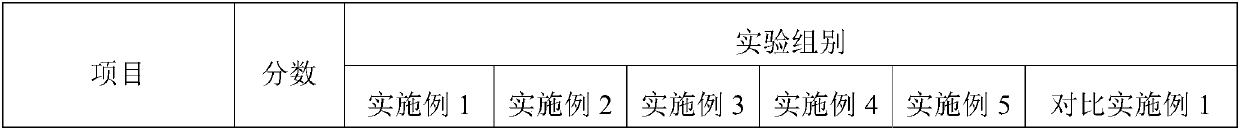

Embodiment 1

[0032] The complex emulsifier of the present embodiment comprises the following components in mass fraction: 30% of water, 27% of sorbitol, 11% of glycerin, 7% of sucrose fatty acid ester, 8% of glyceryl monostearate, 8% of sorbitan mono Stearate (Span 60) 10%, polyoxyethylene sorbitan monostearate (Tween 60) 5%, soluble soybean polysaccharide 2%.

[0033] The application of the compound emulsifier of the present embodiment on making bread comprises the following steps:

[0034] S1: Weigh 500g of flour, 8g of active dry yeast, 5g of salt, 100g of white sugar, 37g of butter, 220g of water, and 5g of compound emulsifier;

[0035] S2: Mix flour and active dry yeast slowly for 2 minutes;

[0036] S3: White sugar and water are mixed and stirred to dissolve, poured into S2 and slowly mixed to form a ball, then changed to fast stirring for 10-15 minutes until gluten is formed;

[0037] S4: Stir at a slow speed, add salt, butter and a compound emulsifier with both emulsification and...

Embodiment 2

[0043] The complex emulsifier of the present embodiment comprises the following components in mass fraction: 30% of water, 10% of sorbitol, 26% of glycerin, 7% of sucrose fatty acid ester, 10% of glyceryl monostearate, 10% of sorbitan mono Stearate (Span 60) 10%, polyoxyethylene sorbitan monostearate (Tween 60) 5%, soluble soybean polysaccharide 2%.

[0044] The application of the compound emulsifier of the present embodiment on making bread is the same as the method of embodiment 1.

Embodiment 3

[0046] The complex emulsifier of the present embodiment comprises the following components in mass fraction: 30% of water, 10% of sorbitol, 22% of glycerin, 7% of sucrose fatty acid ester, 12% of glyceryl monostearate, 12% of sorbitan mono Stearate (Span 60) 10%, polyoxyethylene sorbitan monostearate (Tween 60) 5%, soluble soybean polysaccharide 4%.

[0047] The application of the compound emulsifier of the present embodiment on making bread is the same as the method of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com