Environmentally-friendly natural multielement rock fertilizer

A multi-element, environmentally friendly technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve problems such as crop quality impact, eater diseases, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

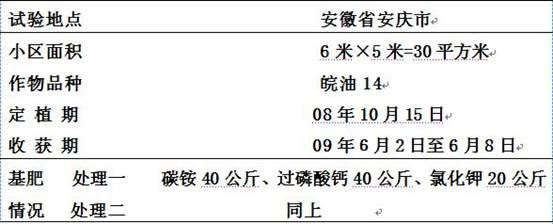

Image

Examples

Embodiment 1

[0045] Preparation of 1000kg environment-friendly natural multi-element rock fertilizer:

[0046] Step 1: Select SiO 2 >57%, A1 2 o 3 >14%, Na 2 O+K 2 O>5% quartz diorite ore, P 2 o 5 Phosphorous metamorphic rock ores >8%, CaO >18%, K 2 Potassium-rich shale ores with O>10% and potassium-containing minerals are mainly potassium feldspar and glauconite; dolomite ores with CaO>25% and MgO>20% are crushed and ground into powder by a crusher respectively, and passed through 200 mesh Sieve, the sieved powder is used for later use, and the particles that do not pass the sieve are repeatedly crushed, ground into powder and sieved for reincarnation to obtain quartz diorite powder, phosphorus-containing metamorphic rock powder, potassium-rich shale powder and dolomite rock powder, and are used for future use;

[0047] Step 2: Weigh the quartz diorite powder, phosphorus-containing metamorphic rock powder, potassium-rich shale powder and dolomite rock powder...

Embodiment 2

[0049] Preparation of 1000kg environment-friendly natural multi-element rock fertilizer:

[0050] Step 1: Select SiO 2 >57%, A1 2 o 3 >14%, Na 2 O+K 2 O>5% quartz diorite ore, P 2 o 5 Phosphorous metamorphic rock ores >8%, CaO >18%, K 2 Potassium-rich shale ores with O>10% and potassium-containing minerals are mainly potassium feldspar and glauconite; dolomite ores with CaO>25% and MgO>20% are crushed and ground into powder by a crusher respectively, and passed through 200 mesh Sieve, the sieved powder is used for later use, and the particles that do not pass the sieve are repeatedly crushed, ground into powder and sieved for reincarnation to obtain quartz diorite powder, phosphorus-containing metamorphic rock powder, potassium-rich shale powder and dolomite rock powder, and are used for future use;

[0051] Step 2: Weigh the quartz diorite powder, phosphorus-containing metamorphic rock powder, potassium-rich shale powder and dolomite rock powder...

Embodiment 3

[0053] Preparation of 1000kg environment-friendly natural multi-element rock fertilizer:

[0054] Step 1: Select SiO 2 >57%, A1 2 o 3 >14%, Na 2 O+K 2 O>5% quartz diorite ore, P 2 o 5 Phosphorous metamorphic rock ores >8%, CaO >18%, K 2 Potassium-rich shale ores with O>10% and potassium-containing minerals are mainly potassium feldspar and glauconite; dolomite ores with CaO>25% and MgO>20% are crushed and ground into powder by a crusher respectively, and passed through 200 mesh Sieve, the sieved powder is used for later use, and the particles that do not pass the sieve are repeatedly crushed, ground into powder and sieved for reincarnation to obtain quartz diorite powder, phosphorus-containing metamorphic rock powder, potassium-rich shale powder and dolomite rock powder, and are used for future use;

[0055] Step 2: Weigh the quartz diorite powder, phosphorus-containing metamorphic rock powder, potassium-rich shale powder and dolomite rock powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com