Spherical calcium oxide adsorbent and preparation method thereof

A technology of calcium oxide adsorption and calcium oxide, applied in chemical instruments and methods, and other chemical processes, can solve problems such as low strength, low manufacturing cost, and easy breakage, and achieve reduced manufacturing costs, improved wear resistance and strength, Excellent adsorption performance

Inactive Publication Date: 2010-01-20

郑州天祥无机材料有限公司 +1

View PDF0 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In order to overcome the shortcomings of the existing calcium oxide desiccant with low strength and easy breakage, the present invention provides a spherical calcium oxide desiccant with high strength, good wear resistance, not easy to break after absorbing water, and low adsorption capacity for air. Low manufacturing cost, can replace 3A molecular sieve, used in insulating glass

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1-5

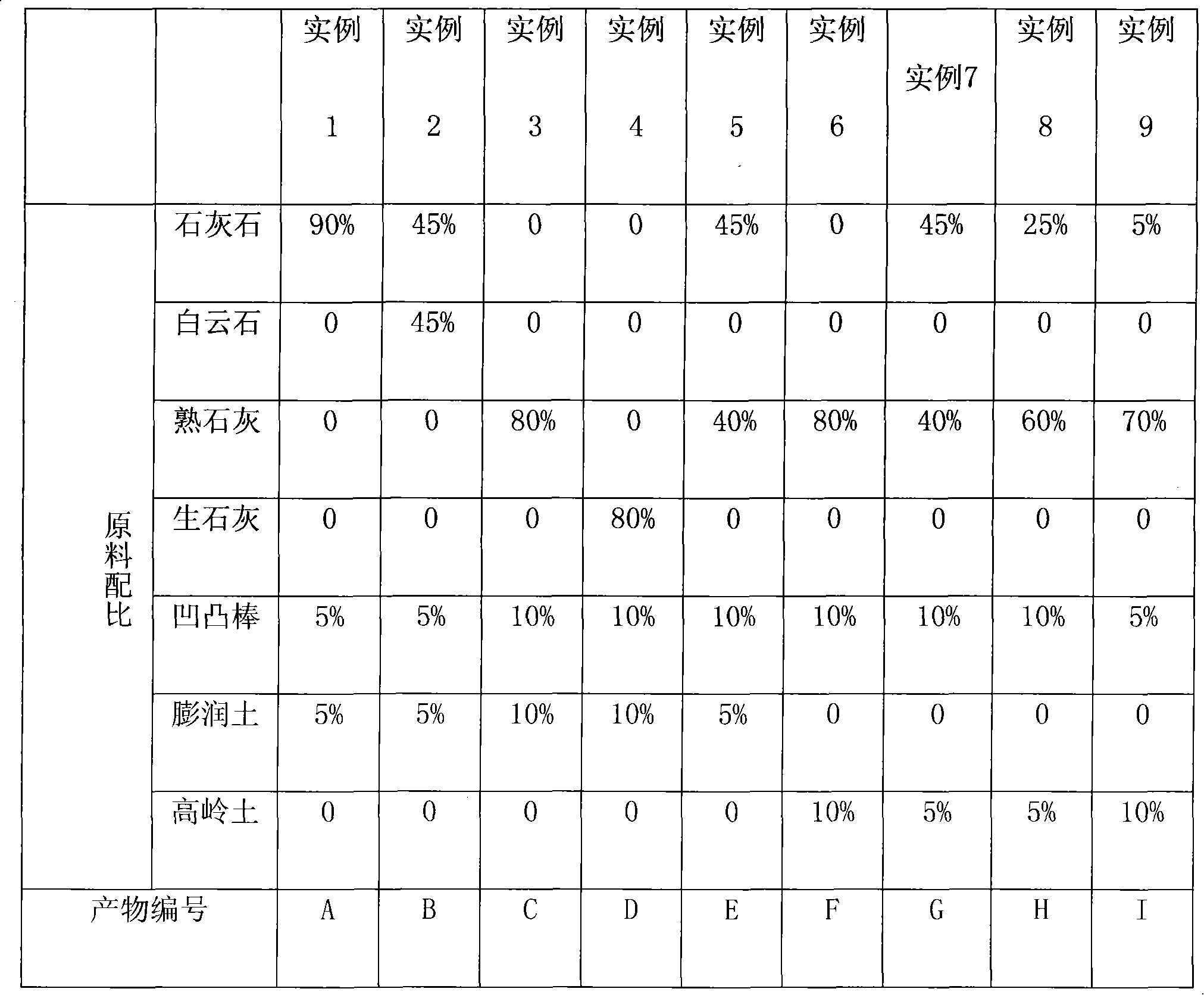

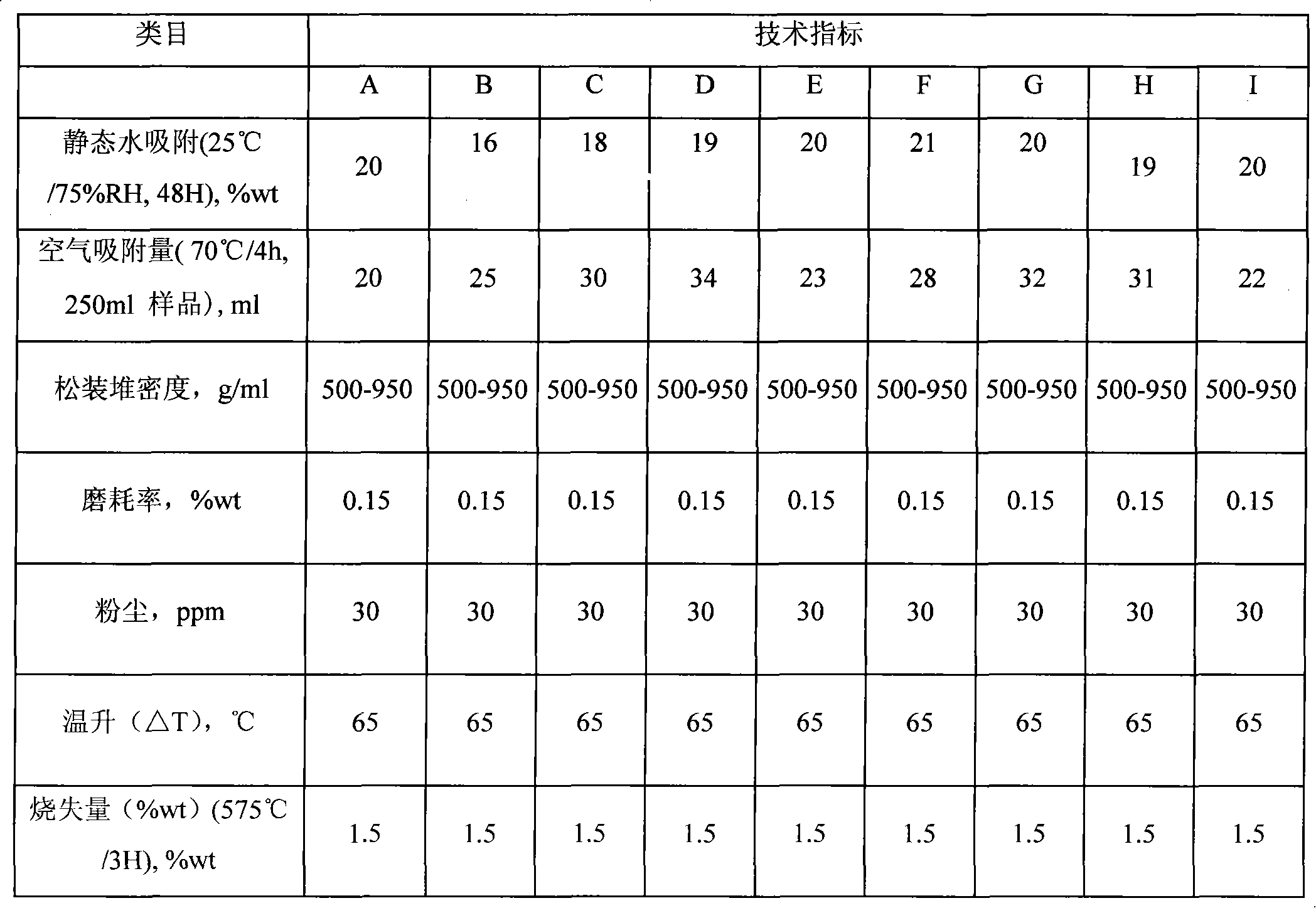

[0025] Prepare spherical calcium oxide desiccant with the method provided by the invention

[0026] Table 1

[0027]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Login to View More

Abstract

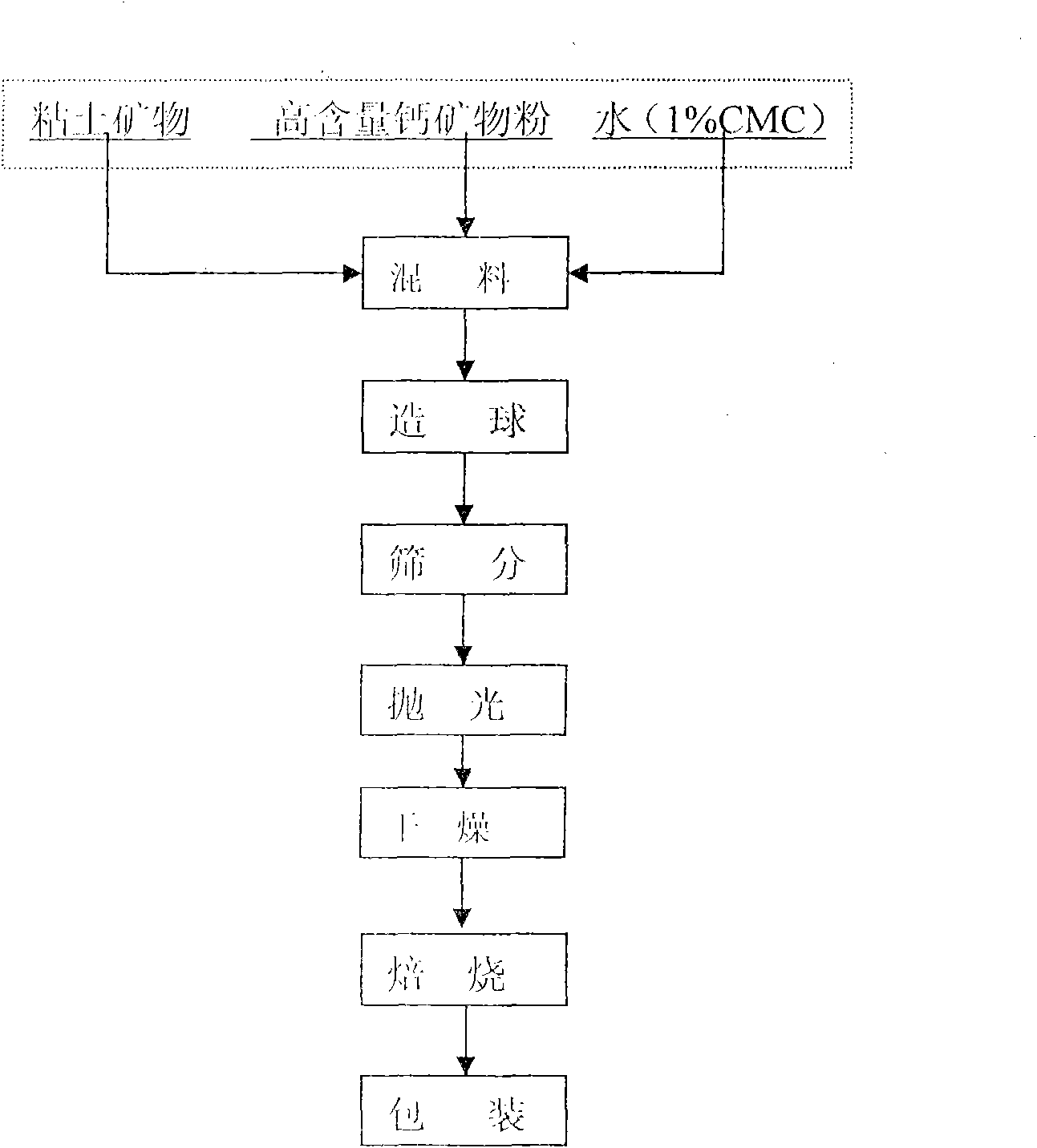

The invention discloses a spherical calcium oxide adsorbent and a preparation method thereof. High-content calcium oxide mineral and clay mineral are used as main raw materials, and the materials are mixed according to the following mixture ratio (in percentage by weight): 50 to 95 percent of the high-content calcium oxide mineral, and 10 to 50 percent of the clay mineral. The preparation method comprises the following steps: mixing the two minerals, molding the mixture in a spherical granulator by using 0 to 1 percent CMC water solution as assistant, screening out spherical granules with certain granularity range by using a two-layer sieve, and further drying, roasting and packing the spherical granules to obtain the spherical calcium oxide adsorbent. The spherical calcium oxide adsorbent comprises the following chemical components: 40 to 90 percent of calcium oxide, 0 to 50 percent of magnesium oxide, 5 to 30 percent of silicon dioxide, 5 to 30 percent of aluminum oxide, and 0 to 30 percent of sodium oxide. The adsorbent has good selective adsorption property and abrasion-resistant property, can be used as a drying agent in the hollow glass industry, can adsorb acid gases such as hydrogen sulfide, hydrogen chloride, sulfur dioxide, chlorine and the like, and can purify industrial waste gases.

Description

Technical field [0001] The patent of the present invention relates to a spherical calcium oxide adsorbent, which can be used as a desiccant and absorbent, used in the field of hollow glass manufacturing and industrial gas purification, and can absorb moisture in air and other gases to dry the gas and adsorb industrial gases Carbon dioxide, sulfur dioxide, hydrochloric acid, ammonia, hydrogen sulfide, etc. in the gas are purified. Background technique [0002] At present, calcium oxide is mostly used as a food desiccant, mainly by calcining, crushing, and screening natural minerals such as calcium carbonate to obtain irregularly shaped particles, which are packed into small bags with air-permeable paper and placed in food bags to absorb air. The moisture in the packaging bag ensures the drying of the food in the packaging bag; due to the irregular shape and low strength of this desiccant, it is easy to be damaged during use, and it is easy to heat up, break and pulverize afte...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01J20/12B01J20/30

Inventor 金松张永全

Owner 郑州天祥无机材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com