Powdery potassium chloride granulation method taking synthesised urea resin as binder

A technology of urea-formaldehyde resin and potassium chloride, applied in fertilizer mixture, fertilization device, application, etc., can solve the problems of high production cost of binder, low strength of fertilizer particles, complicated preparation process, etc., and achieve low production cost and smooth surface , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

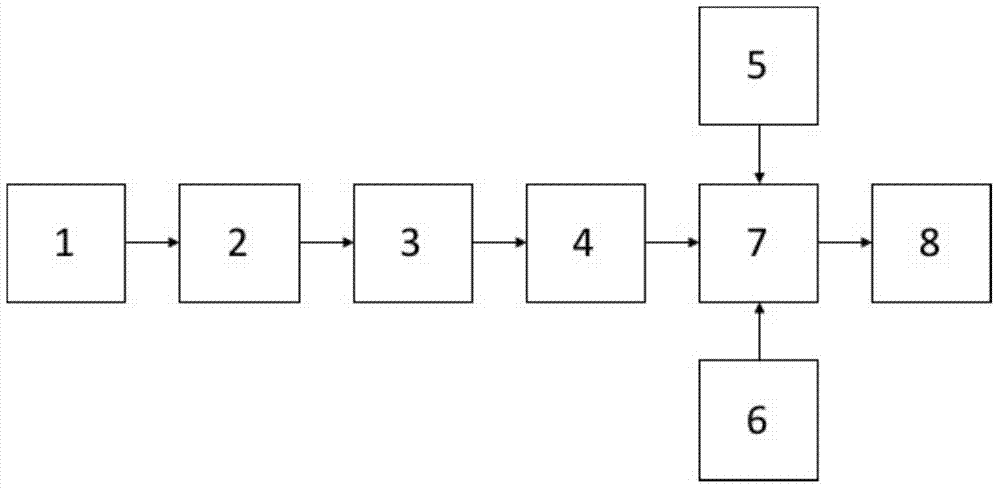

Image

Examples

Embodiment 1

[0020] Weigh 0.15kg of urea and 0.0675kg of formaldehyde solution (the molar ratio of urea and formaldehyde is 2) in the reactor, set the temperature of the reactor to 50°C, and under the action of the stirrer, after the urea is completely dissolved, add a concentration of 1 % sodium hydroxide solution to adjust the pH to 9, add 1.29g of ammonium chloride as a catalyst after a constant temperature reaction at 50°C for 1 hour, adjust the pH to 4 with dilute hydrochloric acid solution, keep the temperature at 50°C, and react for 1 hour before the urea-formaldehyde resin is cured The reactant was transferred to an atomizing tank and water was added to prepare a urea-formaldehyde resin binder suspension with a mass concentration of 25%.

[0021] Sieve the powdery potassium chloride, the sieve fineness is 60 mesh, and remove the irregular large particle potassium chloride of agglomeration. Take by weighing 5kg of sifted powdered potassium chloride in a disc granulator with a disc d...

Embodiment 2

[0023] The processing is as in Example 1, but only differs in the types and amounts of auxiliary substances added. Add 0.3 kg of calcium superphosphate through a 60-mesh sieve. The prepared spherical particle potassium chloride has a spherical rate of 75% and a particle strength of 22N. The content of each component in the dry weight of the spherical potassium chloride granule is: 3.64% of urea-formaldehyde resin, 5.45% of superphosphate, and 90.91% of potassium chloride (54.55% of available potassium).

Embodiment 3

[0025] The processing is as in Example 1, but only the type and amount of auxiliary substances added and the concentration of the urea-formaldehyde resin binder suspension are different. Add 0.15 kg of gypsum powder through a 60 mesh sieve, and the concentration of the urea-formaldehyde resin binder suspension used is 40%. The spheroidization rate of the prepared spherical granular potassium chloride is 65%, and the granule strength is 90N. The content of each component in the dry weight of the spherical potassium chloride granule is: 7.21% of urea-formaldehyde resin, 2.70% of gypsum powder, 90.09% of potassium chloride (54.05% of available potassium).

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com