Method for preparing rare earth doped yttrium aluminum garnet transparent ceramics by utilizing spray granulation modified powder

A doping technology of yttrium aluminum garnet and rare earth, which is applied in the field of laser ceramic materials, can solve the problems of unfavorable late molding and serious powder agglomeration, and achieve the effects of increasing molding density, good mechanical properties, and improving powder fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

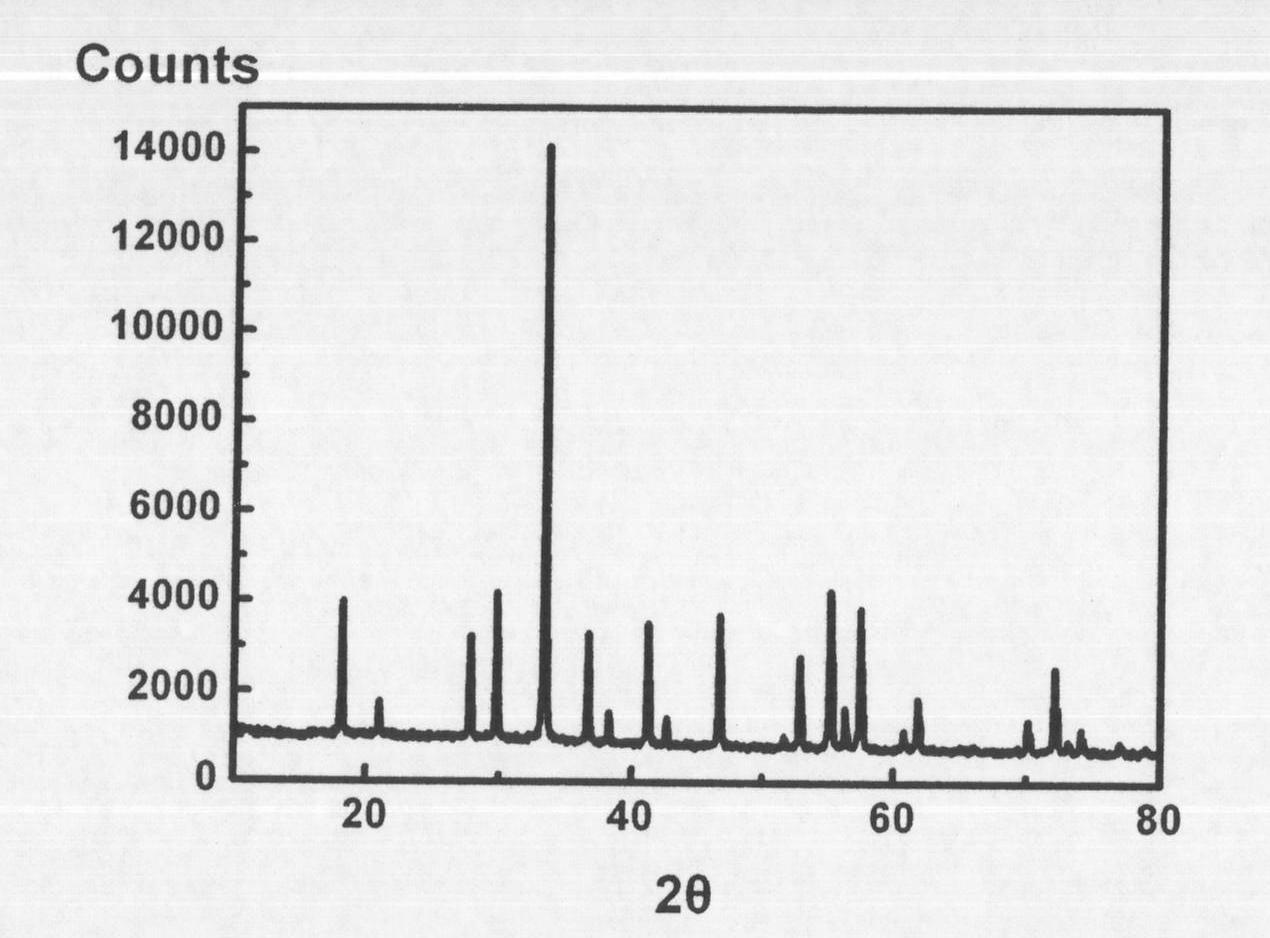

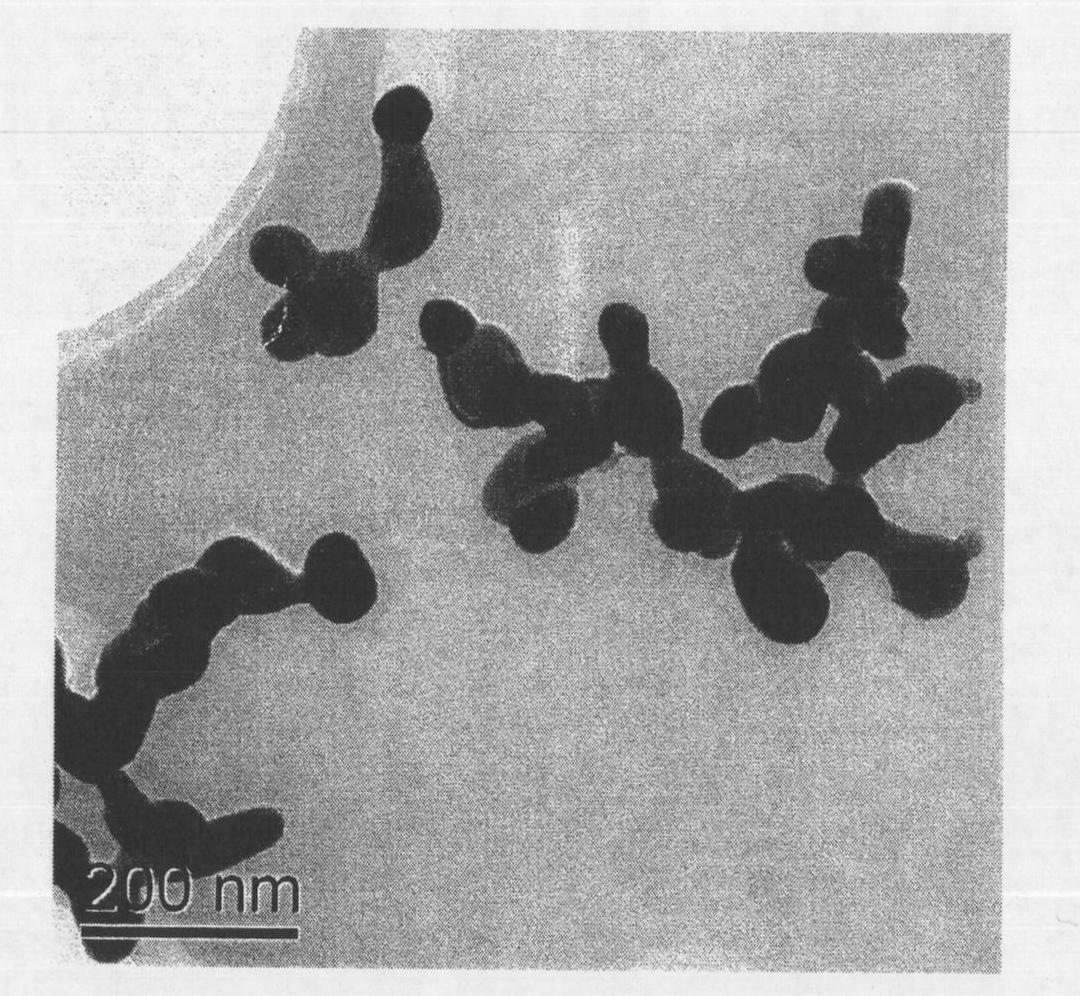

[0026] According to Nd 0.06 Y 2.94 al 5 o 12 Molecular formula, respectively weigh 11.5629g of Al(NO3)3, 6.8190g of Y(NO3)3, 0.1510g of Nd(NO3)3, and prepare a metal mother solution with a total metal ion concentration of 0.1mol / L, under stirring , dropwise into 0.5mol / L excess ammonium bicarbonate solution at a rate of 5ml / min, wherein the two solvents are ethanol-water system, aged for 36 hours, filtered with suction, washed 5 times with deionized water, and washed 2 times with alcohol , the obtained filter cake was dried at 50°C for 24 hours, pulverized and sieved, and the obtained precursor was calcined at 1200°C for 2 hours to obtain 2at% Nd:YAG powder. The powder X-ray diffraction pattern is shown in figure 1 , the transmission electron microscope photo see figure 2 .

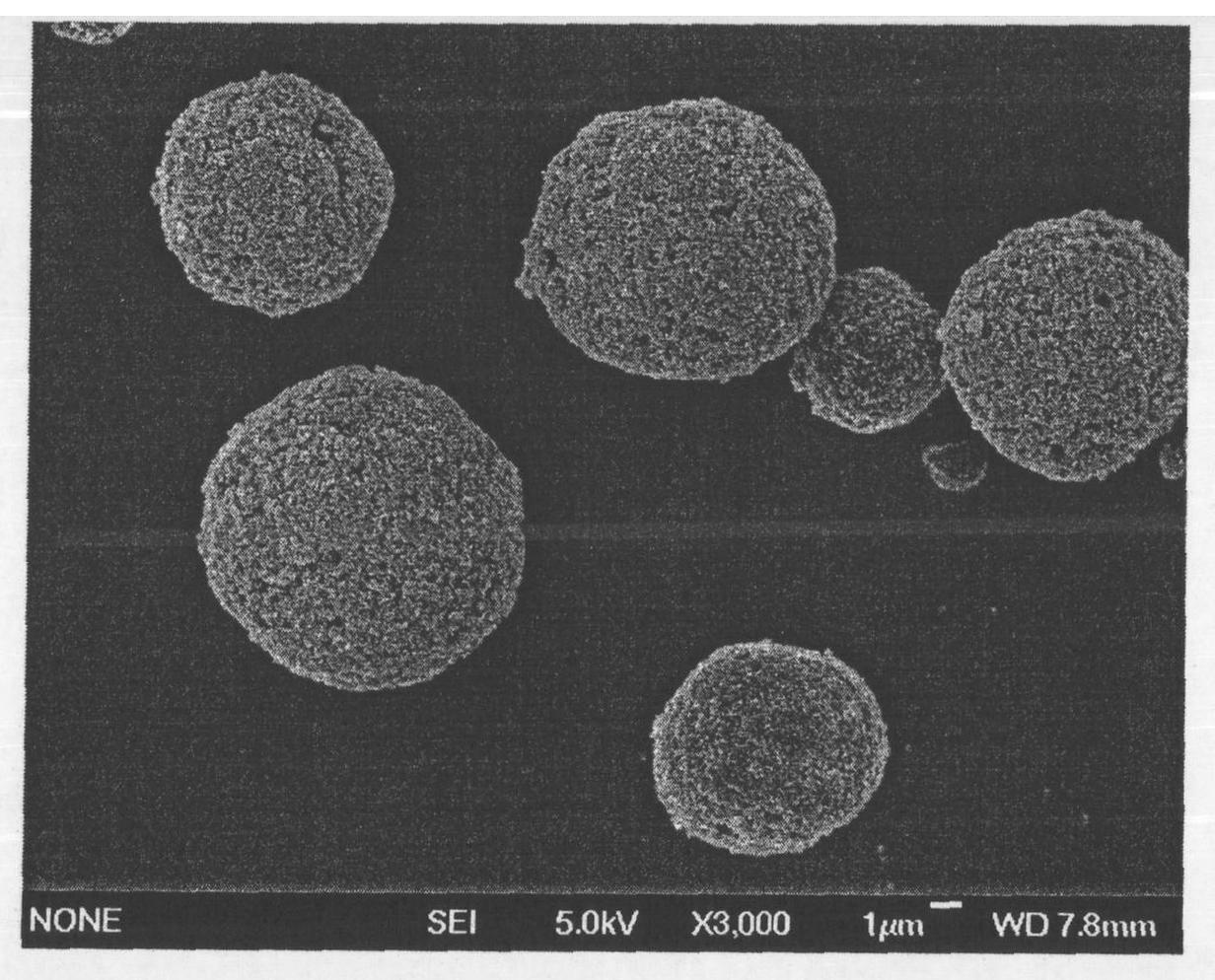

[0027] Put 3.0000g of self-made 2at% Nd:YAG powder, 0.0150g of TEOS and 0.0300g of PVB into a high-purity agate ball mill jar, add 12g of high-purity agate balls, 6g of absolute ethanol, and mix for...

Embodiment 2

[0030] According to Nd 0.06 Y 2.94 al 5 o 12 Molecular formula, weigh 11.5629g of Al(NO3)3, 6.8190g of Y(NO3)3, and 0.1510g of Nd(NO3)3 respectively, and prepare a metal mother solution with a total metal ion concentration of 0.2mol / L. , was added dropwise to 1.0mol / L excessive ammonium bicarbonate solution at a speed of 5ml / min, wherein the two solvents were aged in ethylene glycol-water system for 24 hours, filtered with suction, washed with deionized water for 3 times, and washed with alcohol for 2 The second time, the obtained filter cake was dried at 55°C for 48 hours, crushed and sieved, and the obtained precursor was calcined at 1100°C for 3 hours to obtain 2at% Nd:YAG powder.

[0031] Put 3.0000g of homemade 2at% Nd:YAG powder, 0.0150g of TEOS and 0.0450g of PVB into a high-purity agate ball mill jar, add 12g of high-purity agate balls, 9g of absolute ethanol, and mix for 20 hours with a planetary ball mill. The resulting slurry was spray-dried with an inlet temper...

Embodiment 3

[0033] According to Nd 0.06 Y 2.94 al5 o 12 Molecular formula, respectively weigh 11.5629g of Al(NO3)3, 6.8190g of Y(NO3)3, 0.1510g of Nd(NO3)3, and prepare a metal mother solution with a total metal ion concentration of 0.5mol / L, under stirring , was added dropwise at a speed of 10ml / min to 2.0mol / L excessive ammonium bicarbonate solution, wherein the two solvents were isopropanol-water system and aged for 12 hours, filtered with suction, washed with deionized water for 5 times, and washed with alcohol for 2 The second time, the obtained filter cake was dried at 60°C for 24 hours, crushed and sieved, and the obtained precursor was calcined at 1200°C for 3 hours to obtain 2at% Nd:YAG powder.

[0034] Put 3.0000g of homemade 2at% Nd:YAG powder, 0.0150g of TEOS and 0.0450g of PVB into a high-purity agate ball mill jar, add 12g of high-purity agate balls, 7.5g of absolute ethanol, and mix for 20 hours using a planetary ball mill . The resulting slurry was spray-dried with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com