Preparation of Enrofloxacin microcapsule and method of preparing the same

A technology of enrofloxacin and preparations, which is applied in the field of enrofloxacin microcapsule preparations and its preparation, can solve the problems of poor production environment for workers, complicated process, incomplete packaging, etc., achieve no toxic side effects, high total yield, The effect of expanding the range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

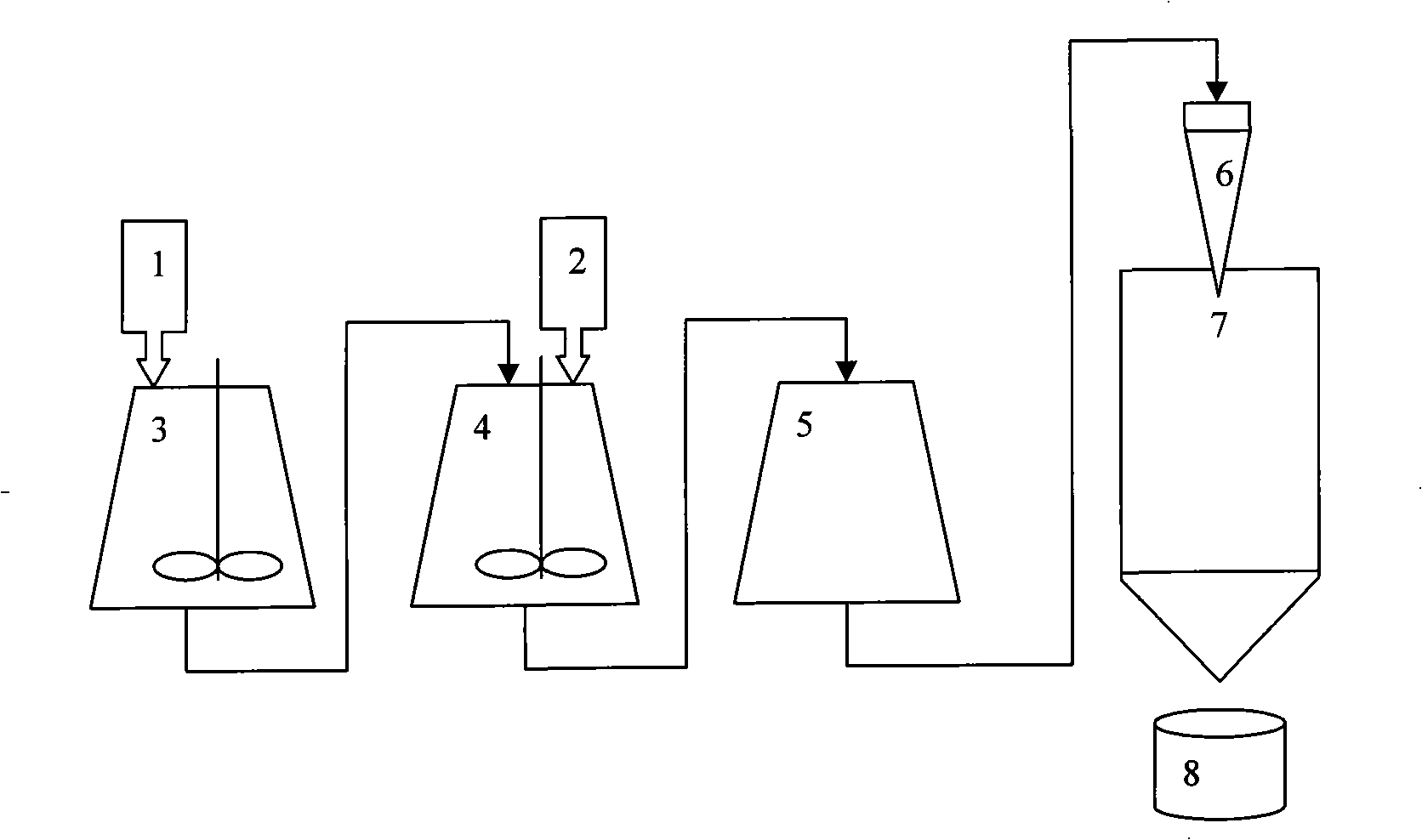

[0032] Select auxiliary material 1 stearic acid (conform to " Chinese Pharmacopoeia " or " United States Pharmacopoeia ", " European Pharmacopoeia ", the quality standard of stearic acid (Stearic Acid) in " British Pharmacopoeia ") 225kg drop into chemical tank 3, as figure 1 As shown, heat to 80°C, stir continuously, until the auxiliary material 1 is completely melted; pump the melted stearic acid from the chemical material tank into the batching tank 4, and at the same time put 25kg of enrofloxacin raw material 2 that has been accurately weighed into the batching tank 4. High-speed emulsification, shearing and stirring for 10 minutes, during which the temperature should be controlled at 80°C; import the prepared material into the storage tank 5, and heat the temperature to 80°C-100°C; start the feeding spray device 6, the spray device 6 can be a high-speed centrifugal spray dryer, which granulates the materials prepared in the storage tank 5 through spray cooling (cooling sys...

Embodiment 2

[0034] Select 120kg of auxiliary material glyceryl monostearate and put it into the chemical material tank, heat to 70°C, and stir continuously until the auxiliary material is completely melted; pump the melted calcium stearate monoglyceride from the chemical material tank Weigh 80kg of enrofloxacin into the batching tank, shear and stir for 8 minutes, during which the temperature should be kept at 80°C; import the prepared materials into the storage tank, and heat the temperature to 80°C-100°C; start feeding Spray device, granulate the materials in the storage tank through spray freezing equipment; sieve and collect the finished product particles with a 200μm-850μm vibrating sieve. Finally, 190 kg of finished enrofloxacin microcapsule preparation (40%) was obtained, the particle size was 200 μm-850 μm, and the yield could reach 95%.

Embodiment 3

[0036] Select 60kg of glyceryl monostearate, 60kg of fat powder, and 20kg of paraffin wax into the chemical material tank, heat to 90°C, and stir continuously until all the auxiliary materials are melted; pump the melted auxiliary materials from the chemical material tank into the batching tank, and at the same time put the Put 60kg of accurately weighed enrofloxacin into the batching tank, shear and stir for 8 minutes, during which the temperature should be kept at 80°C; import the prepared materials into the storage tank, and heat the temperature to 80°C-100°C; start the conveying The material spray device is used to granulate the materials prepared in the storage tank through spray freezing; the finished product particles are collected by sieving with a 200μm-850μm vibrating sieve. Finally, 190kg of finished enrofloxacin microcapsule preparations (30%) were obtained, the particle diameter was 200 μm-850 μm, and the yield could reach 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com