Halogen flame-retardant high-temperature nylon composition and preparation method thereof

A technology of composition and nylon, which is applied in the field of polymer composite materials, can solve the problems of low dosage, inability to obtain light-colored and white products, and discoloration of materials, and achieve the effect of improving discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

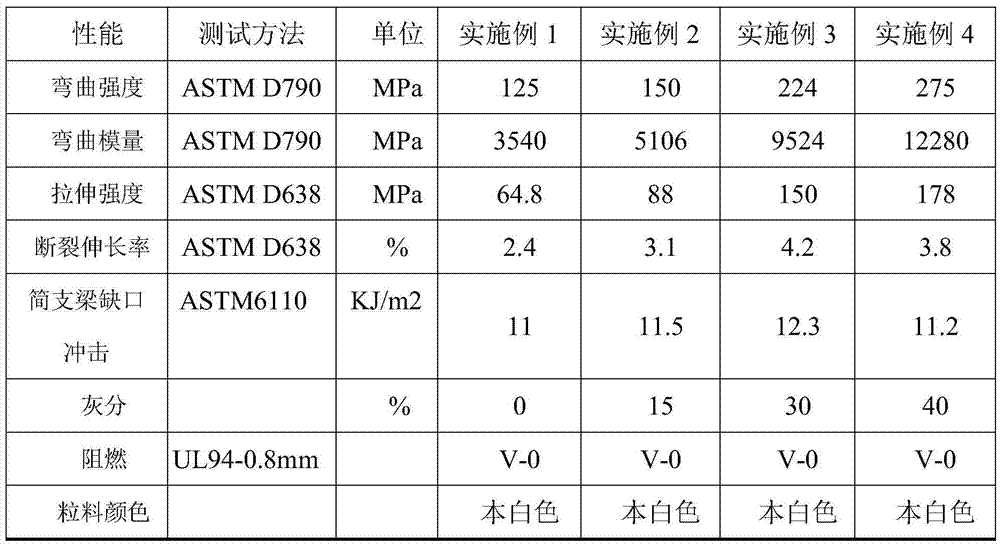

Examples

Embodiment 1

[0028] (1) Dry the high-temperature nylon PA MXD6 at a temperature of 100-120°C for 4-5 hours;

[0029] (2) Add 64.5 parts of dry PA MXD6, 0.3 parts of antioxidant 1098, and 0.2 parts of lubricant A-C540A into the high-speed mixer, and stir in the high-speed mixer for 1-2min; then add 25 parts of Halogenated flame retardant brominated polystyrene, 10 parts of zinc stannate;

[0030] (3) Stir the material weighed in the above step (2) in a high-speed mixer for 3-5min;

[0031] (4) Then the above-mentioned uniformly mixed material is added to the feeding port of the twin-screw extruder;

[0032] (5) The material is melted and extruded by a twin-screw extruder, and granulated;

[0033] The processing technology of the twin-screw extruder is as follows: the temperature of the first zone of the twin-screw extruder is 280°C, the temperature of the second zone is 300°C, the temperature of the third zone is 330°C, the temperature of the fourth zone is 330°C, the temperature of the f...

Embodiment 2

[0035] (1) Dry high-temperature nylon PA66 / 6T at a temperature of 100-120°C for 4-5 hours;

[0036] (2) Add 56 parts of dry PA66 / 6T, 0.5 parts of antioxidant 1098, and 0.5 parts of lubricant A-C540A into the high-speed mixer, and stir in the high-speed mixer for 1-2min; then add 20 parts of Halogenated flame retardant polybrominated styrene, 8 parts of zinc stannate;

[0037] (3) Stir the material weighed in the above step (2) in a high-speed mixer for 3-5min;

[0038] (4) Then the above-mentioned uniformly mixed material is added to the feeding port of the twin-screw extruder, and 15 parts of glass fibers are added through the side feeding port;

[0039] (5) The material is melted and extruded by a twin-screw extruder, and granulated;

[0040] The processing technology of the twin-screw extruder is as follows: the temperature of the first zone of the twin-screw extruder is 270°C, the temperature of the second zone is 290°C, the temperature of the third zone is 320°C, the te...

Embodiment 3

[0042] (1) Dry high-temperature nylon PA9T at a temperature of 100-120°C for 4-5 hours;

[0043] (2) Add 43.5 parts of dry PA9T, 1 part of antioxidant 1098, and 0.5 parts of lubricant A-C540A into a high-speed mixer, and stir in the high-speed mixer for 1-2 minutes; then add 20 parts of halogenated Flame retardant bromotriazine, 5 parts of zinc stannate;

[0044] (3) Stir the material weighed in the above step (2) in a high-speed mixer for 3-5min;

[0045] (4) Then the above-mentioned uniformly mixed material is added to the feeding port of the twin-screw extruder, and 30 parts of glass fibers are added through the side feeding port;

[0046] (5) The material is melted and extruded by a twin-screw extruder, and granulated;

[0047] The processing technology of the twin-screw extruder is as follows: the temperature of the first zone of the twin-screw extruder is 270°C, the temperature of the second zone is 290°C, the temperature of the third zone is 310°C, the temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com