Silver ion antibacterial compatibilizer masterbatch suitable for inorganic filler modified pp

A silver ion antibacterial agent and inorganic filler technology, applied in the field of polypropylene polymer materials, can solve the problems of large amount of silver ion antibacterial agent, discoloration of compatibilizer masterbatch, high hardness, etc., to improve the degree of discoloration and solve the content of antibacterial agent Uniformity problem, the effect of solving the compatibility problem of inorganic filler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

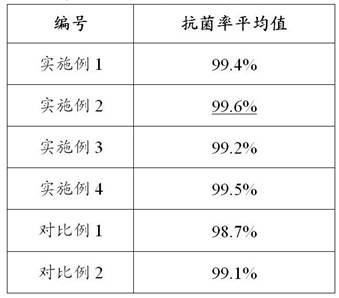

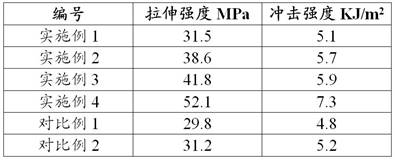

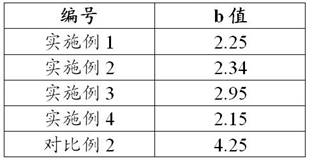

Examples

Embodiment 1

[0055] Composition of antibacterial compatibilizer masterbatch

[0056] Zirconium phosphate silver-loaded antibacterial agent 15 parts

[0057] The composition of antioxidant 1010 and 168 (ratio is 2:1) 9 parts

[0058] Dispersant PP wax 1 part

[0059] 75 parts of maleic anhydride grafted polypropylene

[0060] Preparation method of antibacterial compatibilizer masterbatch

[0061] Step 1: Add 15 parts of zirconium phosphate silver-loaded antibacterial agent (selected from Dongya Synthetic, model AG300), 9 parts of the composition of antioxidant 1010 and 168 (the ratio is 2:1), and 1 part of dispersant PP wax into the high-speed The mixer stirs evenly, and stirs for 3 minutes at 300 rpm.

[0062] Step 2: Using a 12-section screw extruder, add 75 parts of maleic anhydride grafted polypropylene (MAH-g-PP) from the main feed of the twin-screw extruder, antibacterial agent, antioxidant, dispersant The mixture enters from the 4th section side of the twin-screw. The temperatu...

Embodiment 2

[0066] Composition of antibacterial compatibilizer masterbatch

[0067] Zirconium phosphate silver-loaded antibacterial agent 15 parts

[0068] The composition of antioxidant 1010 and 168 (ratio is 2:1) 9 parts

[0069] Dispersant PP wax 1 part

[0070] 75 parts of maleic anhydride grafted polypropylene

[0071] Preparation method of antibacterial compatibilizer masterbatch

[0072] Step 1: Add 15 parts of zirconium phosphate silver-loaded antibacterial agent, 9 parts of the composition of antioxidants 1010 and 168 (the ratio is 2:1), 1 part of dispersant PP wax, and 7.5 parts of maleic anhydride grafted polypropylene into the high-speed The mixer stirs evenly, and stirs for 3 minutes at 300 rpm.

[0073] Step 2: With reference to the steps and process parameters of Step 2 of Example 1, the remaining 67.5 parts of maleic anhydride grafted polypropylene are added from the main feed of the twin-screw extruder, and the step 1 mixture is fed from the fourth section of the twin...

Embodiment 3

[0077] Composition of antibacterial compatibilizer masterbatch

[0078] Take by weighing each component of antibacterial compatibilizer masterbatch with reference to embodiment 2 form, maleic anhydride grafted polypropylene is divided into two parts, wherein the first part maleic anhydride grafted polypropylene is 35 parts, the second part is 35 parts. Toic anhydride grafted polypropylene is 40 parts.

[0079] Preparation method of antibacterial compatibilizer masterbatch

[0080] Step 1: Add 15 parts of zirconium phosphate silver-loaded antimicrobial agent, 9 parts of the composition of antioxidants 1010 and 168 (the ratio is 2:1), 1 part of dispersant PP wax, and 35 parts of maleic anhydride grafted polypropylene into the high-speed The mixer stirs evenly, and stirs for 3 minutes at 300 rpm.

[0081] Step 2: With reference to the steps and process parameters of Example 1 Step 2, the remaining 40 parts of maleic anhydride grafted polypropylene are added from the main feed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com