Anti-discoloration mesh bag of laundry bag and laundry bag

A laundry bag and anti-discoloration technology, which is applied in the field of washing, can solve the problems of non-protective effect on the color of clothes in the bag, increase the degree of color change, and cannot improve the color change of colored/white fibers, etc., so as to improve the color change of mixed washing. , Improve the effect of contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

[0047] Embodiments 1-2 adopt nylon fiber to make laundry bag mesh bag.

[0048] After testing, the laundry bag mesh bag pore size distribution results of Example 1 are shown in Table 1.

[0049] The pore size distribution result of table 1 embodiment 1 laundry bag net bag

[0050] Pore size / μm 116.3 115.0 110.0 105.0 100.0 95.0 90.0 85.0 80.0 75.0 Pore size distribution / % 0.011 0.036 0.138 0.137 0.137 0.138 0.137 0.137 1.540 2.500 Pore size / μm 70.0 65.0 60.0 55.0 50.0 45.0 40.0 35.0 32.3 - Pore size distribution / % 39.475 47.417 1.054 0.888 0.495 0.322 0.880 1.925 0.971 -

[0051] Example 1 The pore size range of the laundry bag mesh bag is 32-117 μm, and the cumulative ratio of the pore size ≤ 110 μm is 98.29%, and the average pore size is 69.5 μm.

[0052] The laundry bag mesh bag of Example 1 has a warp linear density of 2.38 tex, a weft linear density of 3.21 tex, a warp density of 110.0 threads / c...

Embodiment 3~7

[0059] Embodiments 3-7 respectively adopt polyester fiber to make laundry bag mesh bag.

[0060] After testing, the laundry bag mesh bag pore size distribution results of Example 3 are shown in Table 3.

[0061] The pore size distribution result of table 3 embodiment 3 laundry bag mesh bag

[0062] Pore size / μm 22.7 22.0 21.0 20.0 19.0 18.0 17.0 16.0 15.0 14.0 Pore size distribution / % 0.017 0.143 0.196 0.196 0.197 0.214 0.214 0.416 0.801 2.387 Pore size / μm 13.0 12.0 11.0 10.0 9.0 8.0 7.0 6.0 5.5 - Pore size distribution / % 3.225 6.169 4.267 35.074 45.580 0.202 0.197 0.309 0.035 -

[0063] Example 3 The pore size range of the mesh bag of the laundry bag is 5-23 μm, and the cumulative ratio of the pore size ≤ 110 μm is 100%, and the average pore size is 10 μm.

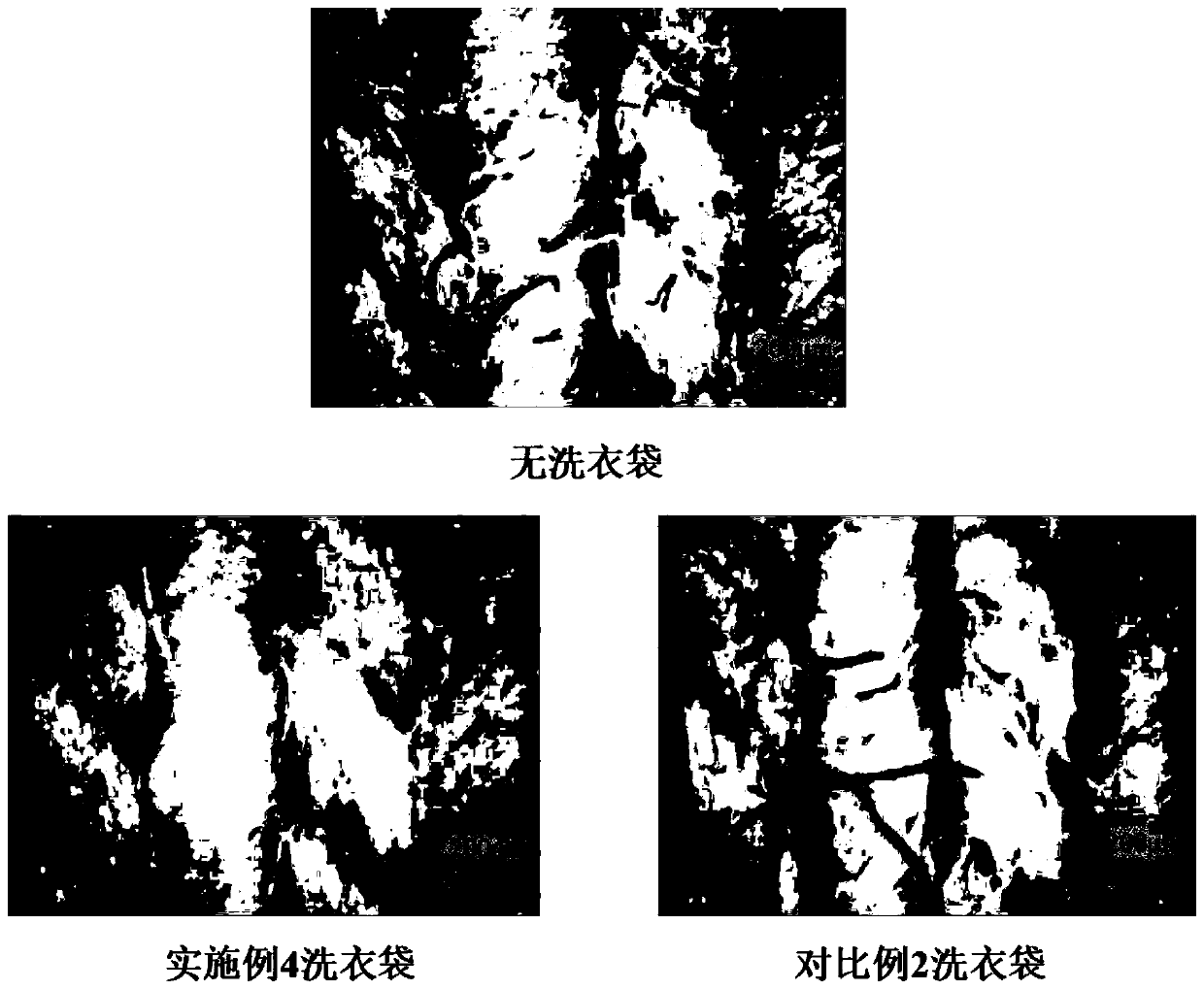

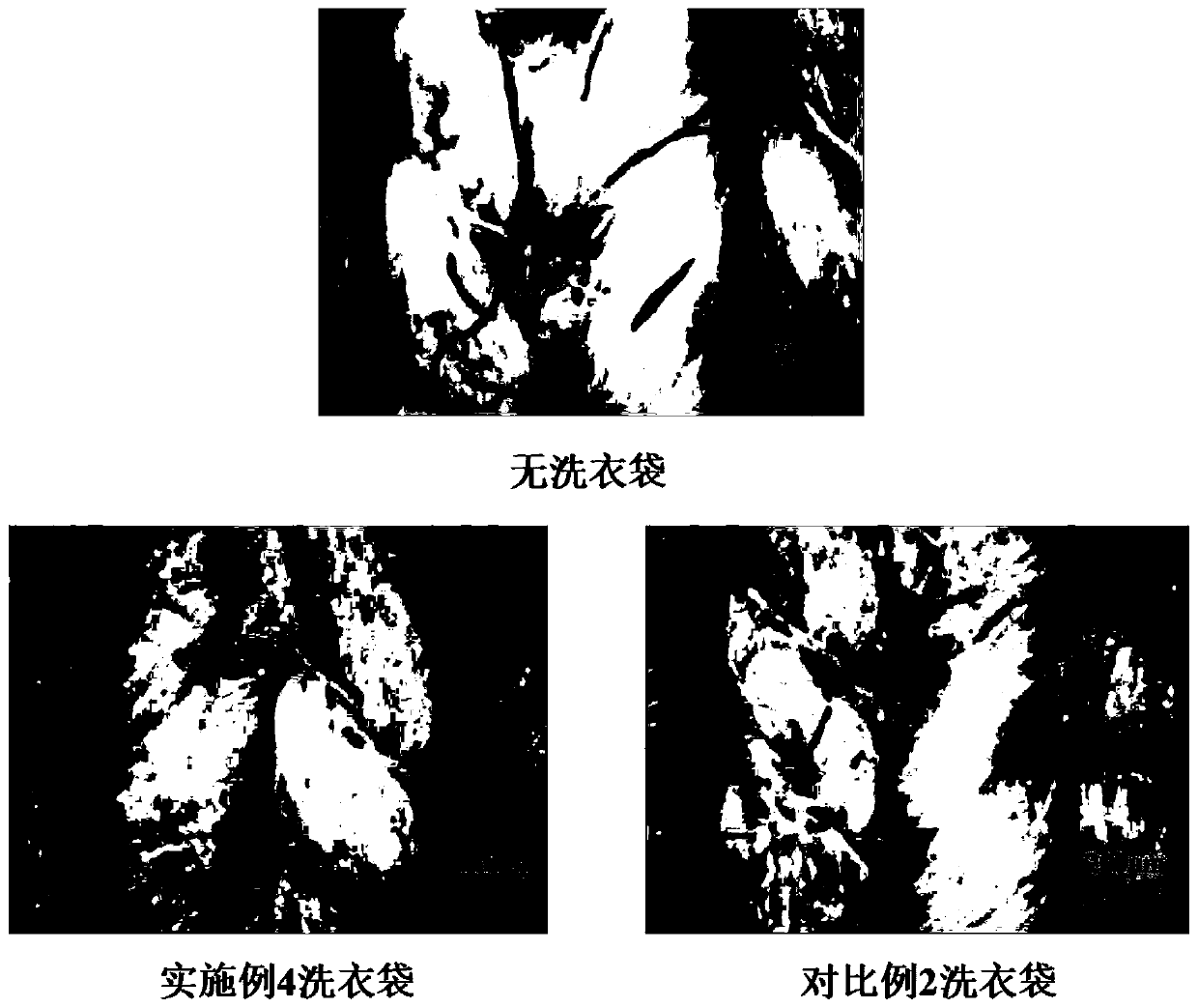

[0064] After testing, the laundry bag mesh bag pore size distribution results of Example 4 are shown in Table 4.

[0065] The pore size distri...

Embodiment 8~11

[0083] Embodiments 8-11 adopt cotton fiber to make laundry bag net bag respectively.

[0084] After testing, the laundry bag mesh bag pore size distribution results of Example 8 are shown in Table 8.

[0085] The pore size distribution result of table 8 embodiment 8 laundry bag mesh bag

[0086] Pore size / μm 27.3 27.0 26.0 25.0 24.0 23.0 22.0 21.0 Pore size distribution / % 0.022 0.061 0.212 0.213 0.212 0.212 0.389 0.402 Pore size / μm 20.0 19.0 18.0 17.0 16.0 15.0 14.0 13.0 Pore size distribution / % 0.716 0.751 0.860 0.979 1.154 1.491 1.533 1.614 Pore size / μm 12.0 11.0 10.0 9.0 8.0 7.0 6.0 - Pore size distribution / % 2.186 2.908 2.217 2.247 3.020 19.967 56.634 -

[0087] Example 8 The pore size range of the mesh bag of the laundry bag is 6-28 μm, and the cumulative ratio of the pore size ≤ 110 μm is 100%, and the average pore size is 6.9 μm.

[0088] The laundry bag mesh bag of Examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com